19

5. INSTALLATION.

•

Read and respect the Safety Information, described

in section 2 of this document. Failure to obey some

of the instructions described in this manual can result in a

serious or very serious accident to persons in direct contact

or in the vicinity, as well as faults in the equipment and/or

loads connected to it.

•

In addition to the user manual itself and the safety instruc-

tions, other documents are available on the Website, on the

CD-ROM or the Pen Drive, referred to as "Recommended

installation". Consult and use them as a guide to define the

sections and protections of the installation.

•

This section introduces the relevant requirements for lo-

cating and wiring the SLC ADAPT X modular UPS. Because

each site has its particularities of location and installation,

it is not the purpose of this section to provide precise step-

by-step instructions, rather it should be used as a guide for

general procedures and practices to be observed by

quali-

fied

personnel (figure recognized and defined in safety in-

structions EK266*08).

5.1. RECEPTION.

•

All subracks are supplied on wood pallet mechanically at-

tached to it, with a cardboard packaging or protection wood

according to model. While the risk of dump is minimized, it

will be handled with caution, especially for subracks with 6

slots because of their greater height and when there is slope.

It is dangerous to manipulate the equipment on

the pallet in an unwise way, as it could overturn

and cause serious or very serious injury to the operators

as a result of the impact due to possible fall and/or en-

trapment. Pay attention to section 1.2.1. of the safety

instructions -EK266 * 08- in all matters relating to the

handling, movement and location of the unit.

•

Use the most suitable means to move the UPS while it is

packed, with a transpalet or forklift.

•

Any manipulation of the equipment will be done according

to the weights indicated in the section «9. Annexes» in the

technical specifications according to model.

5.1.1. Reception, unpacking and contents.

•

Reception. Check that:

The data on the label affixed to the packaging corre-

spond to those specified in the order. Once the UPS is

unpacked, check the previous data with those of the

equipment nameplate.

If there are discrepancies, file the disagreement as

soon as possible, quoting the equipment serial number

and the delivery note references.

It has not suffered any mishaps during transportation

(packaging and impact indicator in perfect condition).

Otherwise, follow the protocol indicated on the label at-

tached to the impact indicator, located on the packaging.

•

Unpacking.

To check the contents it is necessary to remove the

packaging.

Complete the unpacking according to the proce-

dure of section 5.1.3.

•

Content.

The equipment itself.

Documentation of the equipment in computer support

CD-ROM or Pen Drive. In default download from the

Web.

•

Once the reception is completed, it is advisable to re-pack

the UPS until it is put into service in order to protect it

against mechanical shock, dust, dirt, etc.

5.1.2. Storage.

•

Equipment storage shall be done in a dry, ventilated place

and protected from rain, dust, water splashes or chemical

agents. It is advisable to keep each equipment in its original

packaging as it has been specifically designed to ensure

maximum protection during transport and storage.

•

Do not store the devices where the ambient temperature

exceeds the thresholds given in section 'Annexes’.

•

When a battery pack is supplied with the subrack of the

UPS, either in a cabinet, loose to be installed in a cabinet

of its property, to be installed on a rack or in any other way

and not installed together immediately, it will be stored in

a cool, dry and ventilated place, at a controlled temperature

between 20 and 25ºC.

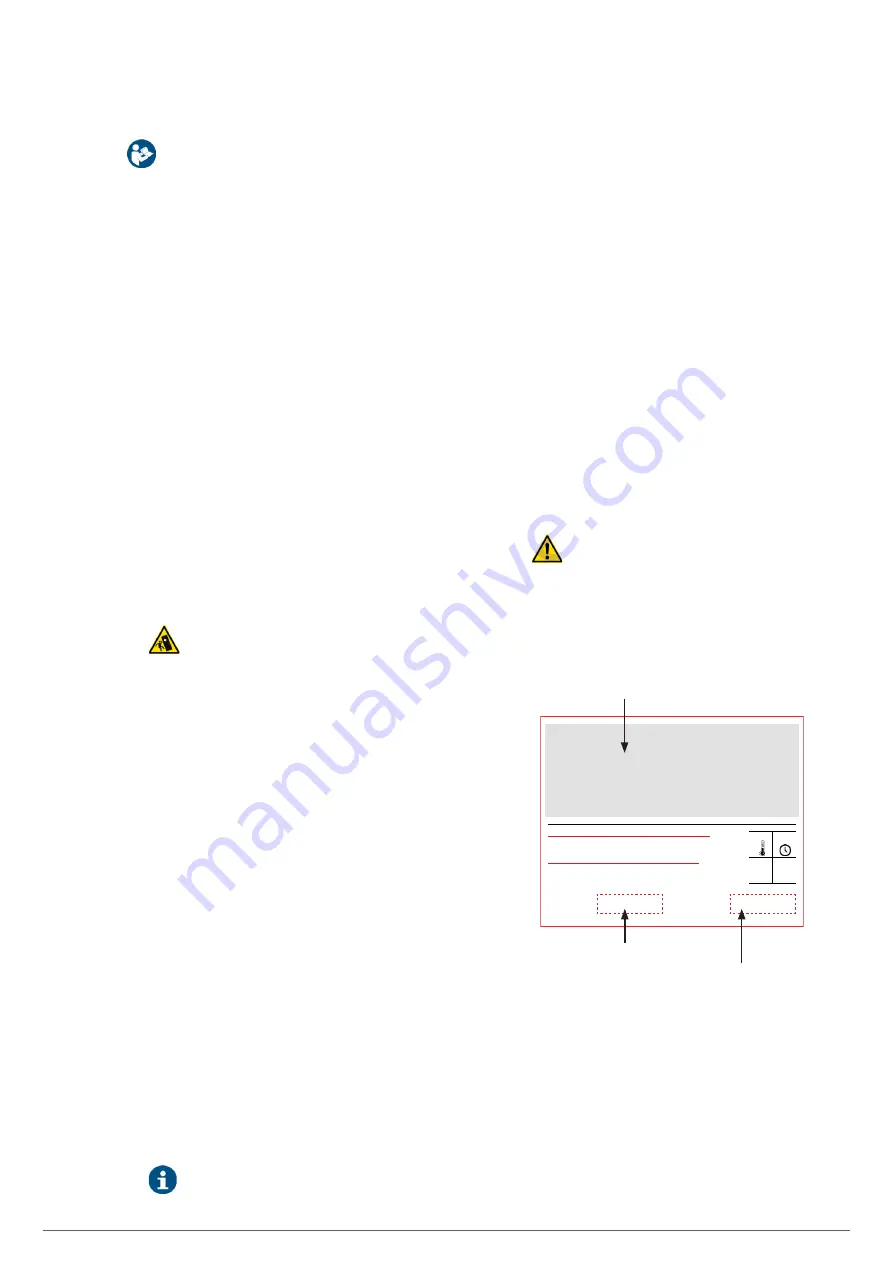

In general and except in particular cases when

batteries are supplied they are hermetically

sealed lead-calcium batteries. To avoid degradation

during storage, they must be recharged at the indicated

intervals according to the temperature at which they

are exposed (see date of last charge noted on the label

affixed to the packaging of the battery unit Fig. 17).

Fecha carga /

Fecha recarga /

Charging date :

Recharging date:

DY933B00 - 401AF000001

BACK MA

TERIAL

MUY IMPORTANTE PARA LA VIDA DE LAS BATERÍAS DE Pb-Ca:

Para evitar

su degradación deben ser recargadas en los intervalos indicados. Respetar

el procedimiento referido en el manual de usuario del equipo.

VERY IMPORTANT FOR THE LIFETIME OF Pb-Ca BATTERIES:

In order to avoid

their degradation, they must be recharged according to the stated interval

times. Respect the procedure referred in the equipment user’s manual.

0 - 20

12

21 - 30

9

31 - 40

5

41 - 50

2,5

Meses /

Months

ºC

Charge date shipped from factory.

Space to write down the date of the new recharge.

**-**-****

Data label corresponding to the model .

Fig. 17.

Label on the packaging of the battery pack.

After the period of time, connect the batteries with the

equipment and this to the mains following the safety

and connection instructions.

Proceed to commissioning. See Section 6.

Leave it in this mode for at least 12 hours.

Once the battery recharging is completed proceed to

stop the equipment, disconnect it electrically and save

the UPS and the batteries in their original packaging,

EMi3

SERVOMOTOR VOLTAGE STABILISER

USER'S MANUAL