25

of the connection cables, as it avoids the entry of foreign

materials and vermin into the enclosure -see Fig. 24-.

If any of these means is not enough or another mode is

preferred, at the base of the subrack there is a mechanized

cover at the user's discretion and in which it can be fitted

with larger cable glands than those ones provided -see Fig.

25-.

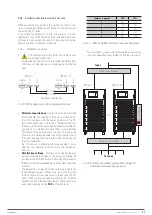

•

The 6-slot subracks have two elliptical holes in the base

of the subrack -see Fig 26-. Make the necessary cuts that

allow the passage of cables.

On the same base and between the two elliptical holes

there is a metal plate that can be extracted and mechanized

for the assembly of cable glands.

It is imperative to fix the cables to the points pro-

vided as shown in Fig. 26, so as do not obstruct the

air cooling outlet.

5.4. PROTECTIVE DEVICES AND CROSS SECTION OF THE

CONNECTION CABLES.

5.4.1. Input, bypass and output.

•

The subracks do not incorporate protections, nor switches

to operate by the user, except a manual bypass switch in

the rear side of the equipment.

In addition, models with 2 and 4 slots have a static bypass

circuit breaker switch on the rear side, but should be con-

sidered as internal protection.

•

Protection or external manual bypass panel:

It is necessary to have an external protection panel

provided with the switches of input, output, and static

bypass (the last one on models with separate bypass

line only).

In addition it is highly recommended to include a

manual bypass switch to facilitate preventive mainte-

nance or repairing operations, so we will refer to it as

a manual bypass panel instead of a protection panel.

For parallel systems of 6-slot subracks, it is essential to

have a manual bypass panel. The panel switches must

allow a subrack to be isolated from the set of systems

in parallel in the event of any anomaly and to feed the

loads with the rest, either during preventive mainte-

nance or during the failure and repair of some of them.

•

On request we can supply an external protection panel or

manual bypass panel for a single unit or a manual bypass

panel for a parallel system.

You can also choose to manufacture it, depending on the

version and configuration of the equipment or system avail-

able and the documentation downloaded from the Website

or attached on the CD-ROM or Pen Drive related to the

"Recommended installation".

•

On the nameplate of the subrack you can check all

the values referring to the main characteristics re-

lated to the equipment. However, the currents indicated

correspond to the higher power model manufactured in that

subrack at the same voltage and configuration of the input

and output. That is, considering that it incorporates all the

modules for which it has capacity.

•

In the documentation downloaded from the website

or supplied with the CD-ROM or Pen Drive, the user

manual, the EK266*08 safety instructions and the informa-

tion on the "Recommended installation", technical data and

single-line diagrams on the connection of the system to the

installation, are also available.

These data are useful for determining the minimum protec-

tions and cross cable sections to be installed at the input

and output of the ADAPT X, taking into account their nom-

inal voltage, input-output configuration and the number of

modules installed in parallel in the subrack.

It is possible to opt for any of the two solutions in

relation to the size of the panel protections:

a.

Protections size according to the power installed in the

subrack. For future upgrading will require the updating

of the sizes when the protection is adjusted to the in-

stallation.

b.

Protections size considering maximum upgrading

power or up to where future scaling extension is envis-

aged. This option is the most economically beneficial if

future expansions are envisaged.

It is recommended that the cross cable section of the panel

be suitable for option “

b.

”.

•

In order to determine the particular technical features of

the system in the respective table of specifications, only

the number of modules working in parallel will be taken

into account, but not those ones that operate in redundant.

Pay attention to the notes indicated in the tables and that

are conditioning to determine the respective data provided,

although the installer will be responsible for defining the

particularities of the installation (cross cble sections, pro-

tections size, ...), since it is the person who has all the infor-

mation regarding the system's location environment.

All values given in the tables are calculated for a

max-

imum total cable length of 30 m

between the distribu-

tion panel, equipment and loads.

For longer lengths correct the cross sections to avoid

voltage drops, respecting the regulations or standards

corresponding to the country.

In the same documentation and for each configuration,

the information for «N» units in parallel (in 6-slot sub-

rack), as well as the characteristics of «Backfeed pro-

tection» is available.

•

In parallel systems, the length and cross section of

the cables from the protection panel to each UPS

and from the UPS to the panel will be the same for all of

them without exception.

•

The cross section of the cables must always be considered

in relation to the size of the terminals of the power block

and/or switches, so that they are correctly fastened in their

entire section for optimum contact between the two ele-

ments.

•

Only rated currents are printed on the nameplate of the

equipment as indicated by the EN-IEC 62040-1 safety

standard. For the calculation of the input current, the power

factor and the equipment's own performance have been

considered.

•

If peripheral input, output or bypass elements such as

transformers or autotransformers are added to the UPS or

parallel system, the currents indicated on the nameplates

of these elements must be considered in order to use the

appropriate sections, in compliance with the local and/or

national Low Voltage Electrotechnical Regulation.

•

When a galvanic isolation transformer is added to an UPS

EMi3

SERVOMOTOR VOLTAGE STABILISER

USER'S MANUAL