21

SALICRU

4.3.7. Connection in parallel.

4.3.7.1. Introduction to the redundancy.

N+X is usually the most reliable power structure. N means the

minimum quantity of equipments that the total load needs; X

means the quantity of redundant equipments, so it means, the

quantity of faulty UPSs that the system can allow at the same

time. As higher is X, the highest will be the reliability of the

system. For those cases where the reliability is the most impor-

tant point, N+X will be the optimal mode.

Up to 4 equipments can be connected in parallel to set a share

and redundant output in power.

4.3.7.2. Installation and parallel operating.

•

Communication line (COM) is a very low voltage circuit

of safety. To preserve the quality, it has to be installed

separate from other lines that have dangerous voltages (energy

distribution line).

•

Parallel connection bus

. Use the bundle with 25 signal ca-

bles with mesh and DB25 connectors in the ends to joint up

to 4 equipments as maximum. Each bundle has a male and

female connector in the ends, which have to be connected in

the correlative equipments. It is essential to close the loop of

the parallel bus.

The length of the parallel cable has 3 metres and it can't be

extended under any other concept due to the risk of interfer-

ences and communication failures that it could cause.

•

In those installations with only one UPS, the “Jumper”

(cable as bridge mode) connected from factory be-

tween the terminals

JP1

and

JP2

has to be kept in this place.

For equipments connected in a parallel system, this “Jumper”

has to be removed.

Proceed according to your installation or otherwise the UPS

or parallel system will not work.

•

The installation of the parallel systems, has to be provided

by a switchgear panel with individual protections for input,

output, static bypass (this last one for

TWIN/3 PRO

> 10 kVA

models only), also a manual bypass with mechanical lock,

see figures 12 and 13.

This switchgear panel allows isolating only one equipment from

the system, against any failure and feed the loads with the rest

of equipments during the preventive maintenance or its fixing. In

the same way, it allows removing an equipment in parallel and

replace it or put it in parallel again once it is fixed, but without

breaking the power supply to the loads.

Under request a manual Bypass panel can be supplied for a

single equipment or particular system.

•

Regarding the protection panel, it is better to size it for future

foreseen upgrading. This way, both the installation of any new

UPS in the parallel system is easier, and the risks due to elec-

trical discharge are minimized because the low voltage panel

is manoeuvred for those cases that it is not possible to shut-

down the loads.

•

Respect the connection procedure for input and bypass

(

TWIN/3 PRO

> 10 kVA) described in the previous sections

of this chapter.

•

Respect the established procedure to make the connection of the

battery modules for those equipments with extended back up time,

which has been described in the previous sections of this chapter.

•

Respect the established procedure to make the connection of

the output (loads), which has been described in the previous

sections of this chapter.

• • •

Input circuit breakers

Output circuit breakers

M

anu

al

B

yp

as

s

UPS nr 1

UPS nr 2

UPS nr

"N"

Input

To loads

• • •

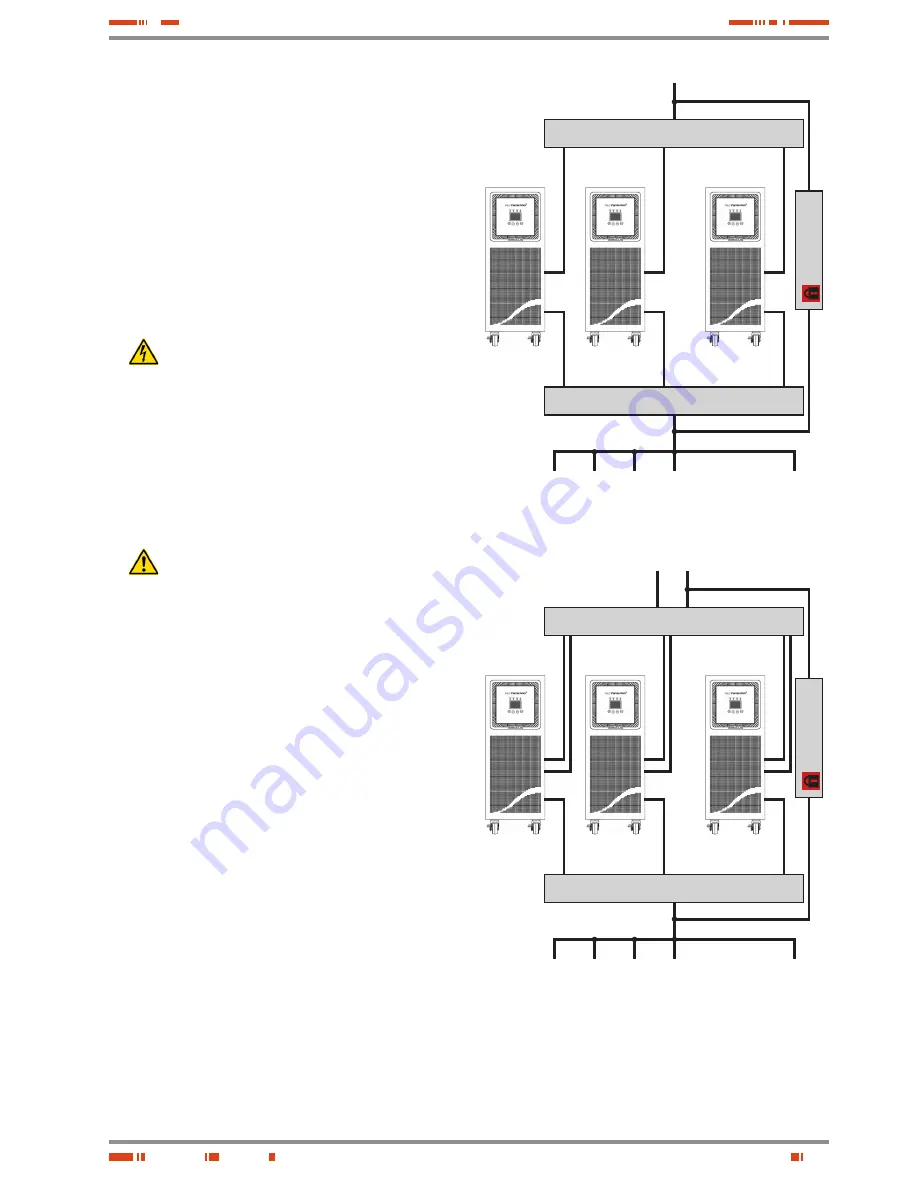

Fig. 12.

Parallel installation of TWIN PRO and TWIN/3 PRO UPSs up to 10

kVA, with protection and manual bypass panel.

• • •

Input and bypass circuit breakers

Output circuit breakers

M

anu

al

B

yp

as

s

UPS nr 1

UPS nr 2

UPS nr

"N"

Input

To loads

• • •

Bypass line

Fig. 13.

Parallel installation of TWIN/3 PRO series > 10 kVA, with

manual bypass and protection panel.

•

Respect the established procedure to make the connection

of the output and batteries of the equipment, which has been

described in the previous sections of this chapter.

Summary of Contents for SLC TWIN PRO Series

Page 2: ......

Page 43: ...43 SALICRU...