English

88

Salmson 05/2015

motor impeller unit from the pump housing (pay attention to the

previous dismantling and subsequent installation of the spacer).

• Transport eyes that have been installed at the motor housing are

not approved for the transport of the whole pump and not for sep-

arating or pulling out of the motor impeller unit from the pump

housing.

• Only lift the pump with approved lifting gear (e.g.

block and tackle,

crane, etc.; see chapter 3 “Transport and interim storage” on

page 71).

• When installing the pump, an axial minimum wall/roof clearance of

the motor’s fan cover of 400 mm is to be maintained.

NOTE:

Shut-off devices shall be installed upstream and downstream from

the pump in all cases, in order to avoid having to drain the entire sys-

tem when checking or renewing the pump.

CAUTION! Risk of property damage!

A volume flow going against or with the direction of flow (turbine

operation or generator operation) can cause irreparable damage to

the drive.

• A non-return valve shall be installed on the pressure side of each

pump.

NOTE:

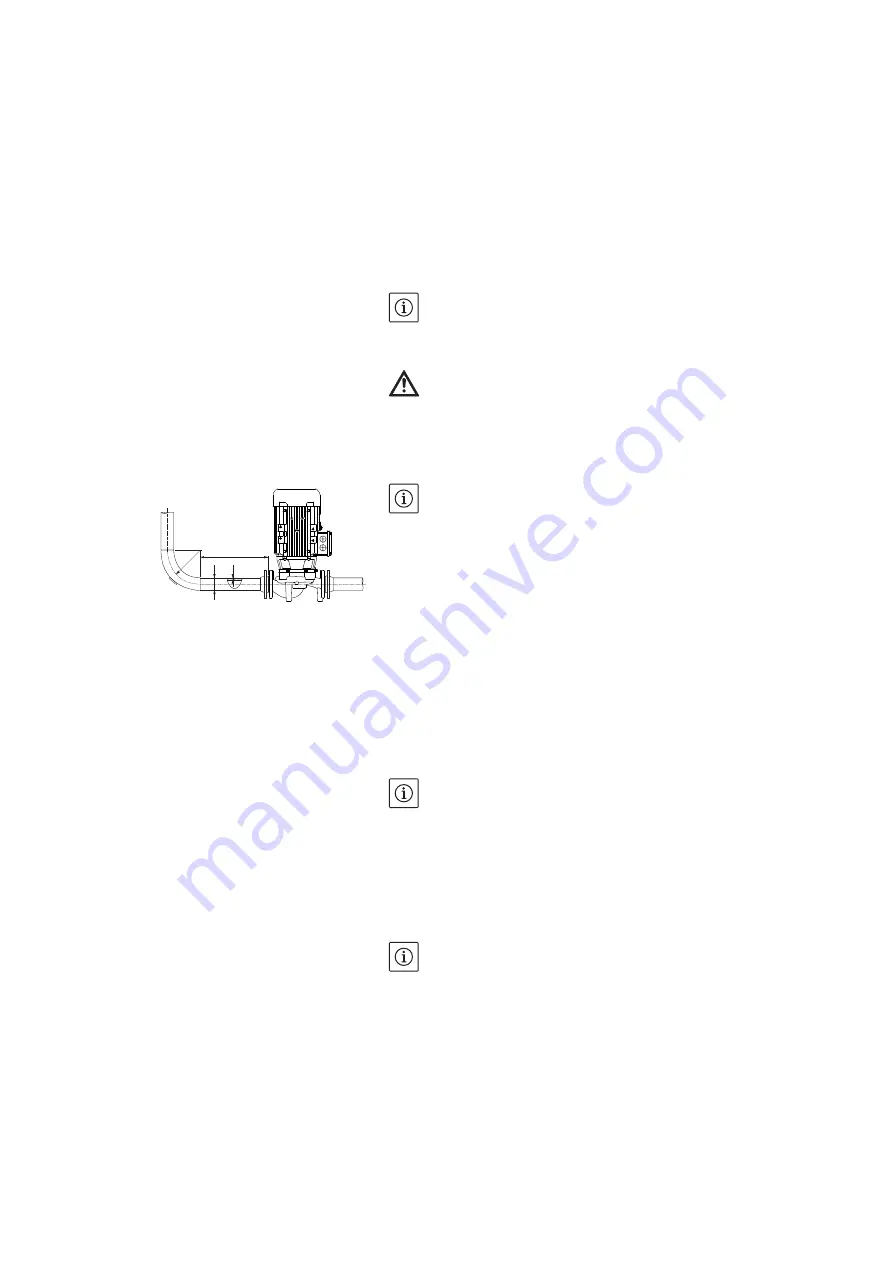

A settling section must be provided before and after the pump, in the

form of a straight pipe. The length of this settling section should be at

least 5 x DN of the pump flange (Fig. 26). This measure serves to avoid

flow cavitation.

• The pipes and pump must be free of mechanical stress when installed.

The pipes must be fixed in such a way that the pump is not supporting

the weight of the pipes.

• The direction of flow must correspond with the direction arrow on the

pump housing flange.

• The air vent valve at the lantern (Fig. 7, Item 19) always has to be

pointed upwards if the motor shaft is horizontal (Fig. 6/7). If the motor

shaft is vertical, any orientation is permitted.

• All installation positions except for “motor facing down” are allowed.

• The electronic module must not face downwards. If required, the

motor can be turned after loosening the hexagon head screws.

NOTE:

After loosening the hexagon head screws, the differential pressure

sensor is attached to the pressure measuring lines only. When turning

the motor housing, make sure that the pressure measuring lines are not

bent or kinked. Furthermore, while rotating the motor housing, it must

be ensured that the housing O-ring seal does not become damaged.

• For the permitted installation positions, see chapter 7.1 “Permitted

NOTE:

Ixens Bloc series monobloc pumps are to be mounted on a sufficiently

strong base or mounting brackets.

• The pump support foot for the Ixens Bloc must be firmly screwed onto

the foundation to ensure that the pump has a secure footing.

Fig. 26: Settling section before and after

the pump

r

5 x DN

d

s

r

⬇

2,5 · (d · 2s)

Summary of Contents for IXENS

Page 2: ......

Page 3: ......

Page 8: ...Fig 7 Ixens 13 20 22 21 15 16 17 18 19 14 13 12 11 10 9 8 7 4 3 2 1 6 5 20b 20a ...

Page 75: ...Français Notice de montage et de mise en service Ixens Ixens Bloc 67 ...

Page 137: ...English Installation and operating instructions Ixens Ixens Bloc 129 ...

Page 203: ...Italiano Istruzioni di montaggio uso e manutenzione Ixens Ixens Bloc 195 ...

Page 335: ......