42

English

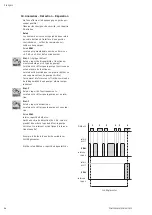

Principal dimensions and connection

MULTI-VE (Fig. 3)

NEXIS-VE (Fig. 3)

7.4 Electrical connections

DANGER!

Danger of death!

Inadequate installation and electrical connections

can be life-threatening.

• Electrical connections shall only be made by

approved specialised electricians and in compli-

ance with the applicable regulations.

• Accident prevention regulations must be

observed.

• Do not forget to connect to earth.

CAUTION!

Danger of mains overload!

An inadequate mains design can lead to system

failures and can lead to cable fires due to mains

overload.

CAUTION!

Danger of material damage!

A connection error would damage the converter.

The power cable shall never touch the pipe or the

pump ; make sure that it is protected against any

humidity.

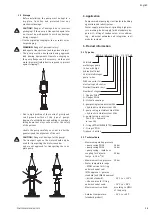

(Pos. a) The power cable (3 earth) must be

fed through the cable gland M25. Nonallocated

cable glands must remain sealed with the plugs

provided by the manufacturer (see below).

- (Pos. b) The sensor, external setpoint and

[aux.]/[ext.off] input cable must be necessarily

screened and must be inserted into the gland M12

or M16. The cable glands of the converter are

adapted to the assembly with a shielding braid

(see below).

• The electric characteristics (frequency, voltage,

nominal current) of the motor-converter are

mentioned on the pump identification sticker

(item 19). Check that the motor-converter com-

plies with the mains supply used.

• The electric protection of the motor is integrated

into the converter. The parameters take into

account the characteristics of the pump and must

ensure its protection and the one of the motor.

• In case of impedance between earth and neutral

point, install a protection before motor-convert-

er.

• Provide a fuse-disconnecting switch (type gF) to

protect the mains installation (Fig. 1, 2, item 11).

a

b

١

٢

٣

٤

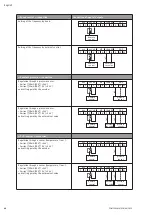

Pump type

Version PN16

Version PN25

A

B

C

D

E

F

G

ØH

D

E

F

G

ØH

6”

200/400

100

212

180

157

204

50

G1“ 2xM10 172

250

75

DN25 4xM12

600

100

212

180

157

204

50

G1“1/4 2xM10 172

250

75

DN32 4xM16

1000

130

255

215

190

250

80

G1“1/2 2xM12 190

280

80

DN40 4xM16

1600

130

255

215

190

250

90

G2“ 2xM12 190

300

90

DN50 4xM16

8”

2200

130

296

215

250

300

90

DN50 4xM16 250

300

90

DN50 4xM16

3600

170

296

240

250

320

105

DN65 4xM16 250

320

105

DN65 8xM16

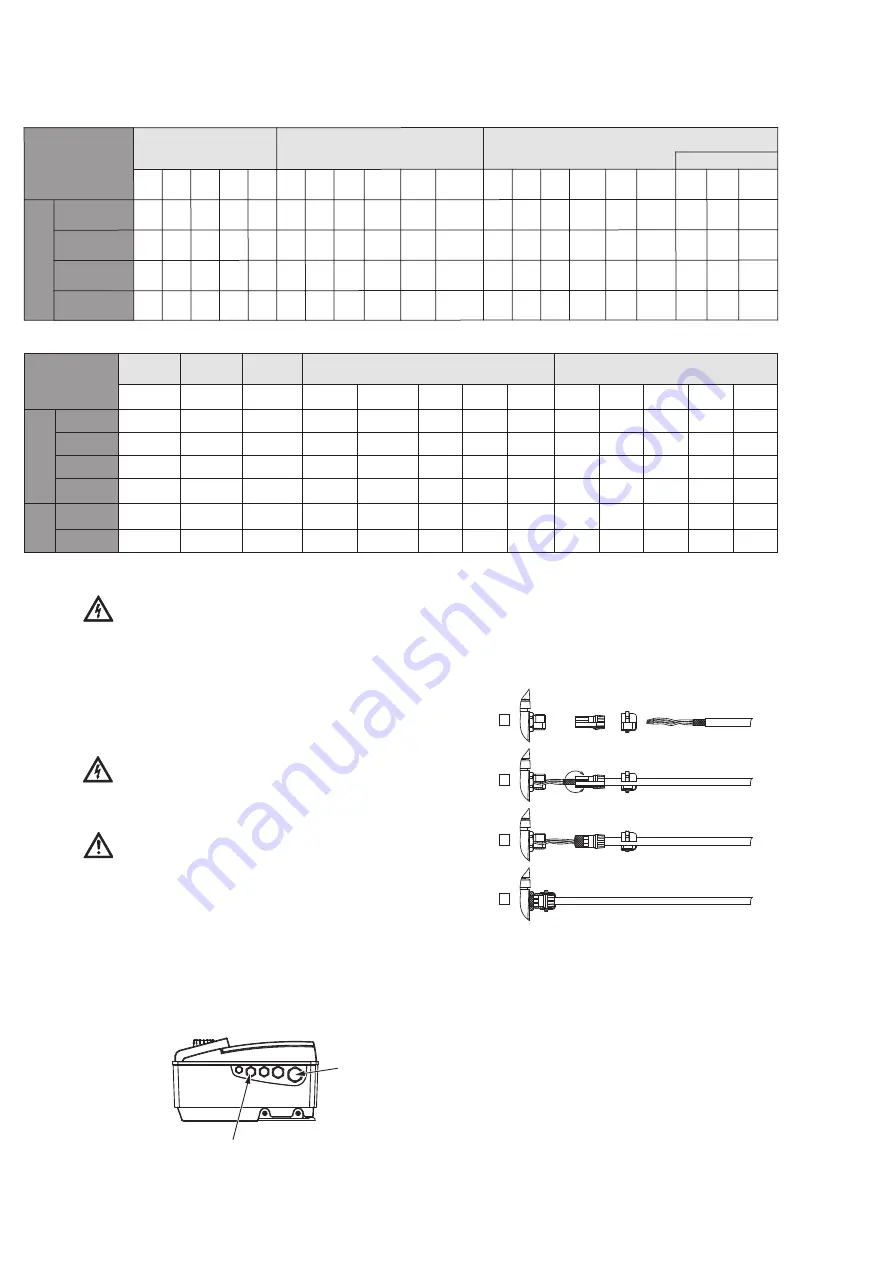

Pump type

Version PN16

Version PN25

Victaulic

B

C

D

G ØT

A

E

F

S

ØU

R

A

E

F

ØS

ØU

R

E

F

R

6”

200

212 180 100 20 12 157 204 50

75 M10

G1”

172 250 75

85

14 DN25 210 50 Ø42,4

400

212 180 100 20 12 157 204 50

75 M10 G1”1/4 172 250 75 100 18 DN32 210 50 Ø42,4

800

252 215 130 20 12 187 250 80 100 M12 G1”1/2 187 280 80 110 18 DN40 261 80 Ø60,3

1600/6

252 215 130 20 12 187 250 90 100 M12

G2”

187 300 90 125 18 DN50 261 80 Ø60,3

POMPES SALMSON 06/2013

Summary of Contents for MULTI-VE Series

Page 2: ......

Page 3: ......

Page 5: ...5 11 7 6 1 13 3 2 7 100 mm Mini 200 mm Mini 100 mm Mini HA 2 BP Fig 1...

Page 6: ...8 9 12 5 11 2 3 2 7 7 4 4 6 13 10 ou or ou or 100 mm Mini HC Fig 2...

Page 8: ...Fig 4...

Page 9: ...2 14 1 Fig 5...

Page 10: ...10 17 16 ou or 15 Fig 6 10 ou or 17 15 16 Fig 7...

Page 11: ...17 16 15 Fig 8...

Page 12: ...19 18 Fig 9 Fig 10...

Page 13: ...Fig 11...