57

English

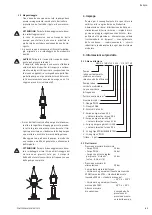

8.4 Starting up

WARNING!

Danger of burn!

Depending on conveyed fluid and the operating

cycles of the pump, surface temperature (pump,

motor) can exceed 68°C.

• Take necessary means to avoid injuries!

CAUTION!

Danger of material damage!

The pump must not operate at zero flow (closed

discharge valve) for more than 10 minutes with

cold water (T°C < 40°C) and more than 5 minutes

beyond 60° C.

• We recommend to ensure a minimum flow of

about 10 % of the pump nominal flow to avoid

any vapour lock at the top of the pump.

• Keep the discharge valve closed.

• Start the pump.

• Open draining plug to drain air. If no water leaks

within 20s, close the plug and stop the pump,

then wait for 20s to allow the settling of the air.

• Start again the pump.

NOTE: If necessary (particularly if the suction

height exceeds 5 m) repeat these operations.

• If water leaks at draining plug (it means the pump

delivers its pressure), slowly open the discharge

valve. The pump has to be primed.

• Check pressure stability at discharge with a

manometer, if instability, perfect air draining.

• In case of failure, do the filling in again and start

the operation again.

• To perfect air draining, close the discharge valve

and the draining plug, then stop the pump 20s,

start the pump again and open the draining plug.

Do it as long as air comes out.

• Open the discharge valve in order to have the

wished working point.

• Check that the current input does not exceed the

value indicated on the motor-converter data

plate.

9. Maintenance

Maintenance and repairs may only be carried

out by qualified experts !

It is recommended to have the pump maintained and

checked by an after-sales service technician.

DANGER!

Danger of death!

There is a danger of electrocution, when working

on electrical equipments.

• Only electricians approved by the local electricity

supplier are allowed to work on electrical equip-

ments.

• Before working on electrical equipment, switch it

off and prevent it from being switched on again!

WARNING!

Risk of burn!

High surface temperatures may be reached.

• Allow the pump to cool off before all works.

• Always wear protective clothing and gloves when

working!

• No special maintenance in operation.

• Keep the pump and the motor-converter per-

fectly clean.

• In case of prolonged stopping, if there is no risk

of frost, it is better not to drain the pump.

• The bearing holding the coupling and the motor

bearings are lubricated for their total lifetime and

do not require any lubrication.

• The mechanical seal does not require any main-

tenance in operation. It must never operate dry.

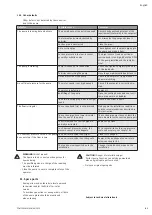

Replacement frequencies

NOTE: These are only recommendations, the

replacement frequency depends on the operat-

ing conditions of the unit , i.e.:

• Temperature, pressure and type of conveyed

fluid for the mechanical seal.

• Load and ambient temperature for the motor and

the other components.

• Starting frequency: continuous or intermittent

running.

POMPES SALMSON 06/2013

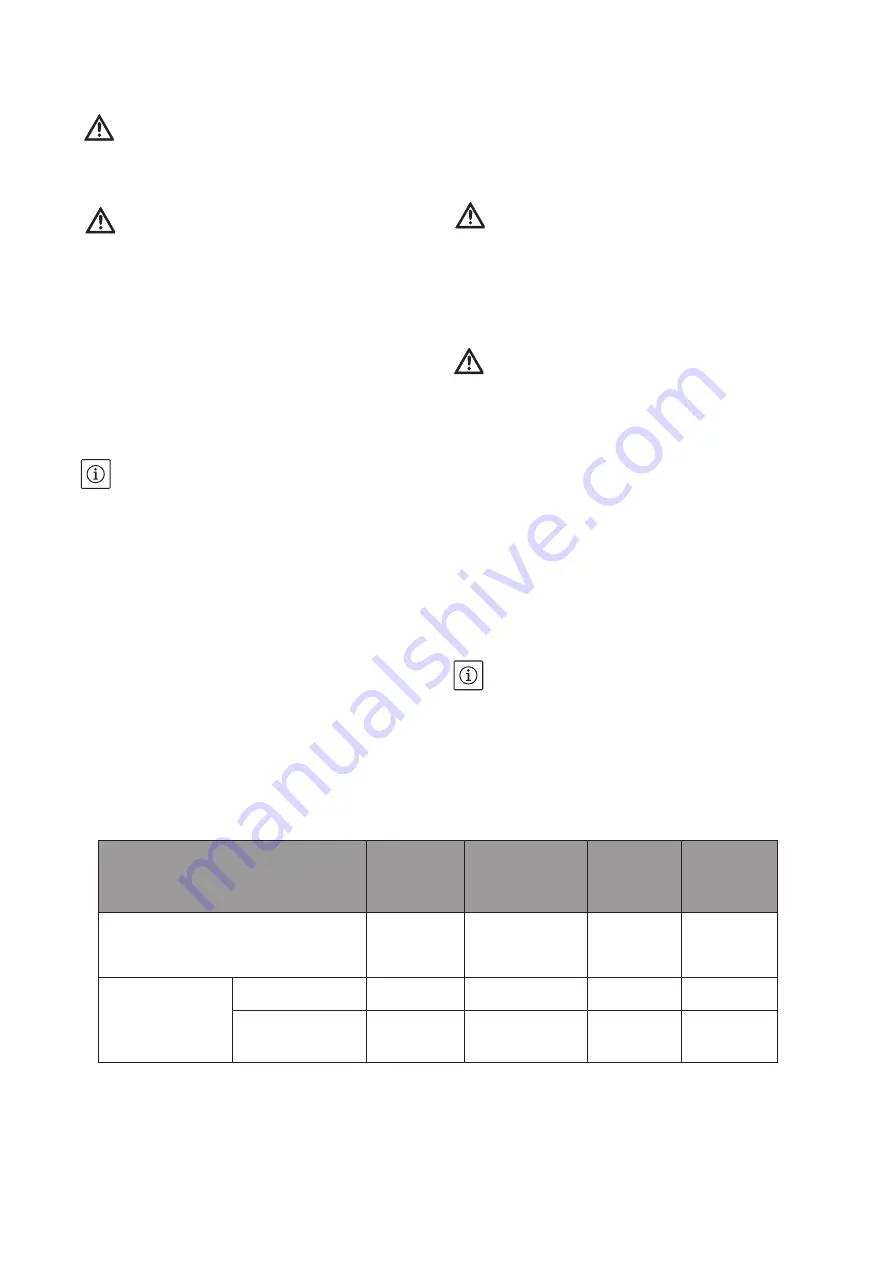

Parts or components subject to wear

Mechanical

seal

Pump and motor

bearings

Converter

Motor

winding

Indicative operating lifetime

10 000 h to

20 000 h

12 000 h to

50 000 h

≥ 15 000 h

Amb. maxi

40°C

25 000 h

Amb. maxi

40°C

Replacement

frequency

Continuous

1 to 2 years

1,5 to 5 years

1 to 3 years

3 years

15 hours per day

9 months per year

2 to 4 years

3 to 10 years

-

6 years

Summary of Contents for MULTI-VE Series

Page 2: ......

Page 3: ......

Page 5: ...5 11 7 6 1 13 3 2 7 100 mm Mini 200 mm Mini 100 mm Mini HA 2 BP Fig 1...

Page 6: ...8 9 12 5 11 2 3 2 7 7 4 4 6 13 10 ou or ou or 100 mm Mini HC Fig 2...

Page 8: ...Fig 4...

Page 9: ...2 14 1 Fig 5...

Page 10: ...10 17 16 ou or 15 Fig 6 10 ou or 17 15 16 Fig 7...

Page 11: ...17 16 15 Fig 8...

Page 12: ...19 18 Fig 9 Fig 10...

Page 13: ...Fig 11...