38

SALMSON 12/2013

English

• Highly flammable materials are always to be kept

at a safe distance from the product.

• Danger from electrical current must be eliminat-

ed. Local directives or general directives [e.g. IEC,

VDE etc.] and local power supply companies

must be adhered to.

2.6 Safety instructions for installation and mainte-

nance work

The operator must ensure that all installation and

maintenance work is carried out by authorised

and qualified personnel, who are sufficiently

informed from their own detailed study of the

operating instructions.

Work on the product/unit must only be carried

out when at a standstill. It is mandatory that the

procedure described in the installation and oper-

ating instructions for shutting down the prod-

uct/unit be complied with.

Immediately on conclusion of the work, all safety

and protective devices must be put back in posi-

tion and/or recommissioned.

2.7 Unauthorised modification and manufacture of

spare parts

Unauthorised modification and manufacture of

spare parts will impair the safety of the prod-

uct/personnel and will make void the manufac-

turer's declarations regarding safety.

Modifications to the product are only permissible

after consultation with the manufacturer. Original

spare parts and accessories authorised by the

manufacturer ensure safety. The use of other

parts will absolve us of liability for consequential

events.

2.8 Improper use

The operating safety of the supplied product is

only guaranteed for conventional use in accor-

dance with Section 4 of the operating instruc-

tions. The limit values must on no account fall

under or exceed those specified in the cata-

logue/data sheet.

3. Transport and interim storage

When receiving the material, check that it has not

been damaged during transport. If the material

has been damaged during transport, take all nec-

essary steps with the forwarding agent within the

claim period.

CAUTION!

Potential damage due to external

influences. If the delivered material is to be

installed at a later date, store it in a dry place and

protect it from impacts and any external influ-

ences (humidity, frost etc.).

Handle the pump carefully to avoid any damage prior

to installation.

4. Intended use

This pump has been designed to pump hot or cold

water, water/glycol mixtures or other low-viscos-

ity liquids that are free of mineral oil, solid or

abrasive substances, or materials containing long

fibres. Pumping corrosive chemicals requires the

manufacturer’s approval.

CAUTION! Risk of explosion!

Do not use this pump for any flammable or explo-

sive liquids.

4.1 Applications areas

- water distribution and pressure boosting,

- industrial circulation systems,

- process fluids,

- cooling-water circuits,

- fire-fighting and washing stations,

- irrigation systems, etc.

Summary of Contents for Nexis-VE 10

Page 2: ......

Page 3: ......

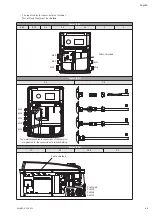

Page 4: ...Fig 1 ...

Page 5: ...Fig 2 ...

Page 6: ...Fig 3 Fig 6 Fig 4 ...

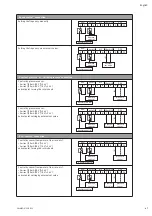

Page 7: ...Fig A1 1 1 ...

Page 8: ...2 4 3 Fig A2 Fig A3 4 3 2 Fig A4 3 4 2 ...

Page 118: ...118 SALMSON 12 2013 Notes ...

Page 119: ...119 SALMSON 12 2013 Notes ...