59

SALMSON 12/2013

English

10. Faults, causes and remedies

WARNING! Risk of electrical shock!

Ensure that any electrical hazard is avoided.

Ensure that the power supply is switched off and

secured against unauthorised switching before

performing any work on the electric system.

WARNING! Risk of scalding!

In case of high water temperatures and high sys-

tem pressures, close the insulating valves upstream

and downstream of the pump.

First, allow pump to cool down.

If the fault cannot be resolved, please

contact the Salmson customer service.

Fault

Possible causes

Remedies

Pump does not operate

No current

Check fuses, wiring and connections

Thermistor tripping device has tripped,

cutting off power

Eliminate any cause of overloading of the

motor

Pumps is running but output is insuffi-

cient

Incorrect direction of rotation

Check the direction of rotation of the

motor and correct it if necessary

Parts of the pump are obstructed by for-

eign bodies

Check and clean the pump

Air in suction pipe

Seal the suction pipe so that it is airtight

Suction pipe too narrow

Install a larger suction pipe

Valve opening is insufficient

Open the valve properly

Pump output is erratic

Air inside the pump

Vent the pump; check that the suction

pipe is airtight. If required, start the

pump for 20 – 30 s – open the venting

plug to remove air – close the venting

plug and repeat the procedure several

times until no more air escapes from the

pump

Pump vibrates or is noisy

Foreign bodies inside the pump

Remove the foreign bodies

Pump is not correctly attached to ground

Retighten the screws

Bearing damaged

Call Salmson customer service

Motor overheats, motor protection trips

Open circuit in one of the phases

Check fuses, wiring and connections

Ambient temperature too high

Provide cooling

Mechanical seal leaks

Mechanical seal is damaged

Replace the mechanical seal

Flow is erratic

In „Constant pressure“ or „Variable pres-

sure“ mode, the pressure sensor is not

adequate

Replace with a sensor with matching

pressure range and accuracy

In „Constant pressure“ mode, the pump

does not stop if the flow is zero

The non-return valve is not tight

Clean it or replace it

The non-return valve is not adequate

Replace it by an adequate non-return

valve

Low tank capacity due to installation

Change it or add a tank to the installa-

tion

Summary of Contents for Nexis-VE 10

Page 2: ......

Page 3: ......

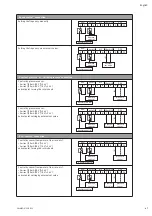

Page 4: ...Fig 1 ...

Page 5: ...Fig 2 ...

Page 6: ...Fig 3 Fig 6 Fig 4 ...

Page 7: ...Fig A1 1 1 ...

Page 8: ...2 4 3 Fig A2 Fig A3 4 3 2 Fig A4 3 4 2 ...

Page 118: ...118 SALMSON 12 2013 Notes ...

Page 119: ...119 SALMSON 12 2013 Notes ...