ENGLISH

10

With

:

c=calorific

capacity

of

fluid

in

J/Kg.K

g=gravity

in

m/s²

H=pump

head

in

m

T

f

=liquid

temperature

in

°C

T

o

=surface

temperature

in

°C

=hydraulic

efficiency

at

duty

point

v

=differential

temperature

Maximum

flow

vs

lifting

height

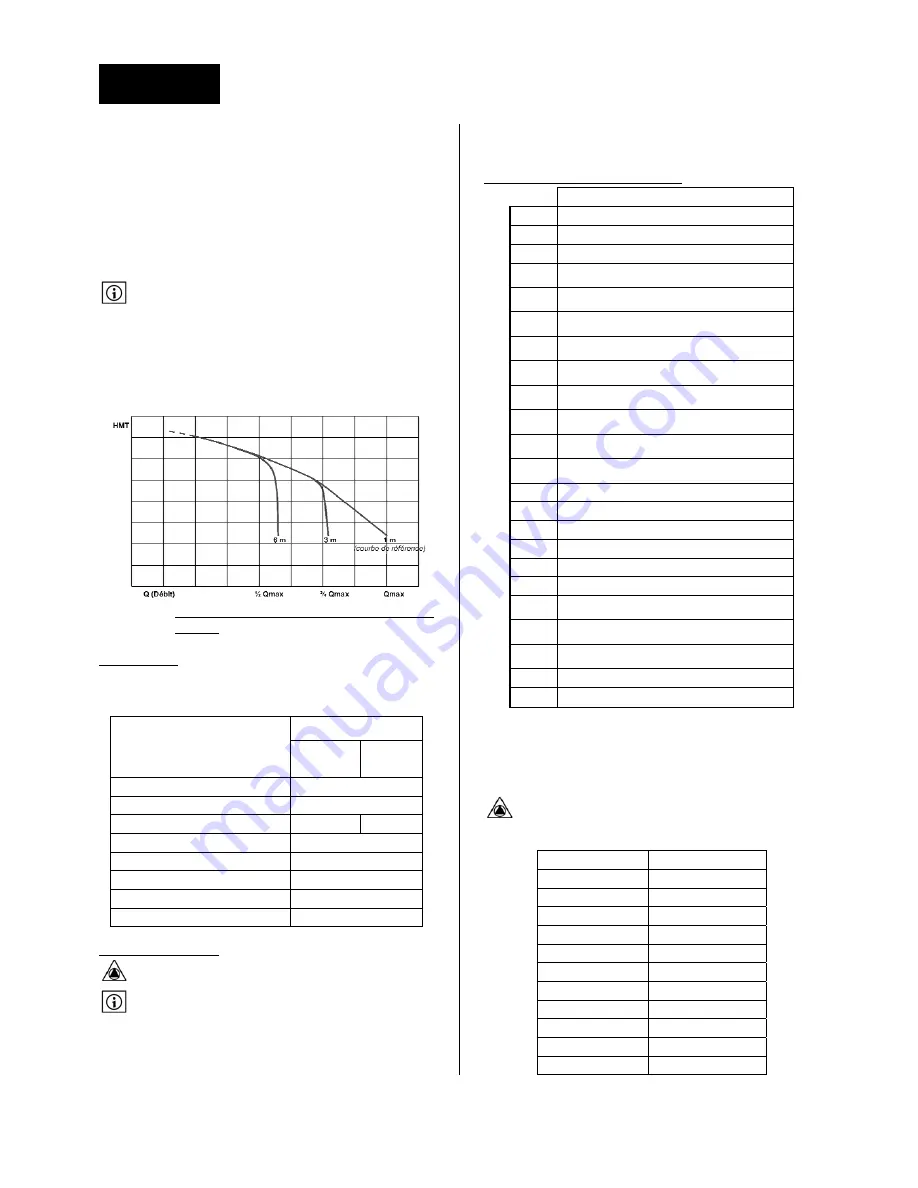

Hydraulic

curves

are

given

for

a

suction

height

of

1

meter.

If

suction

lift

is

higher

than

1

meter

then

the

maximum

pump

flow

will

be

limited

as

follows

:

‐

¾

of

max

flow

if

suction

height

is

3

m

under

suction

flange

level.

‐

½

of

max

flow

if

suction

height

is

6

m

under

suction

flange

level.

See

sketch

below

:

5.2.2.4

Maximum

allowable

speed

and

number

of

starts

per

hour

Maximum

speed

:

The

maximum

speeds

are

indicated

in

the

table

below.

Maximum

allowable

speed

depends

on

critical

speed

of

each

impeller

size

and

on

bearing

bracket

maximum

allowable

speed.

PUMP

SIZE

MAXIMUM

SPEED

RPM

Bi

‐

bloc

and

bearing

bracket

variants

Close

‐

coupled

pumps

S40

;

S41

;

S42

4000

S50

;

S51

;

S80

;

S82

3600

S45

;

S46

;

S60

;

S61

3600

3000

S45

‐

4

;

S63

;

S68

;

S69

;

S83

;

S88

;

S100

;

S108

3000

S65

;

S66

;

S85

;

S105

;

S150

2400

S91

;

S121

;

S161

;

S201

2000

S180

;

S230

1600

S170

;

S220

1200

Number

of

starts

per

hour

:

Wait

for

pump

full

stop

before

starting

up

the

pump

again

to

avoid

damaging

the

motor

and

the

pump.

Starting

frequency

depends

on

motor

type.

Ask

manufacturer

if

necessary.

A

maximum

of

6

starts

per

hour

is

recommended.

5.2.2.5

AUTHORIZED

SPEED

AND

NUMBER

OF

STARTS

PER

HOUR

Operating

limits

for

contiuous

duty

at

50Hz

:

Continuous

duty

S

40

YES

S

45

YES

S

50

YES

S

60

If

flow

much

higher

than

Q

BEP

or

if

abrasive

content

is

high,

choose

bigger

pump

size.

S

63

If

flow

much

higher

than

Q

BEP

or

if

abrasive

content

is

high,

choose

bigger

pump

size.

S

68

If

flow

much

higher

than

Q

BEP

or

if

abrasive

content

is

high,

choose

bigger

pump

size.

S

80

If

flow

much

higher

than

Q

BEP

or

if

abrasive

content

is

high,

choose

bigger

pump

size.

S

83

If

flow

much

higher

than

Q

BEP

or

if

abrasive

content

is

high,

choose

bigger

pump

size.

S

88

If

flow

much

higher

than

Q

BEP

or

if

abrasive

content

is

high,

choose

bigger

pump

size.

S100

If

flow

much

higher

than

Q

BEP

or

if

abrasive

content

is

high,

choose

bigger

pump

size.

S108

If

flow

much

higher

than

Q

BEP

or

if

abrasive

content

is

high,

choose

bigger

pump

size.

S

65

If

flow

much

higher

than

Q

BEP

or

if

abrasive

content

is

high,

choose

bigger

pump

size.

S

85

YES

S105

YES

S121

YES

S150

YES

S161

YES

S180

YES

S201

If

flow

much

higher

than

Q

BEP

or

if

abrasive

content

is

high,

choose

bigger

pump

size.

S230

If

flow

much

higher

than

Q

BEP

or

if

abrasive

content

is

high,

choose

bigger

pump

size.

S170

If

flow

much

higher

than

Q

BEP

or

if

abrasive

content

is

high,

choose

bigger

pump

size.

S220

YES

S300

YES

5.2.2.6

TYPE

OF

HANDLED

FLUIDS

The

pump

is

used

to

handle

clear

or

laden

liquids

with

a

maximum

viscosity

of

500

cSt

(mm²/s).

For

viscosity

higher

than

50cSt,

the

discharge

pressure,

the

flow

and

the

hydraulic

efficiency

must

be

re

‐

calculated.

The

solids

content

in

the

liquid

should

be

limited

to

80g/l

with

no

long

fibers

content.

Dryness

max

=

8%.

Free

passage

depends

on

pump

size:

PUMP

MAX

GAP

(mm)

S45

S46

14x19

S40

S41

S42

Ø20

S60

S61

Ø17

S63

Ø22

S50

S51

S65

S66

S68

S69

Ø25

S83

Ø27

S80

S82

Ø32

S88

S108

Ø35

S91

Ø37

S85

S180

Ø40

S100

S105

S121

Ø45

Summary of Contents for S series

Page 2: ...S INSTALLATION ET MISE EN SERVICE N M S n 4071640 Ed 5 10 13 FRAN AIS...

Page 23: ...FRAN AIS 23...

Page 24: ...24...

Page 25: ...S INSTALLATION AND OPERATING INSTRUCTIONS N M S n 4071640 Ed 5 10 13 ENGLISH...

Page 26: ...2...

Page 48: ...24...