3

IMPORTANT

Make sure all wires securely attached to vehicle or

spreader’s frame. Use wire ties and/or wire clamps to

attach wires. All excess wires must be rolled into bungles

and attached to vehicle or spreader.

2.

Make sure lid is installed and latches are secured

when spreader is in use.

3.

Do not leave material in hopper between uses.

4.

Do not drive with material in hopper.

5.

Always clean/wash hopper at the end of the day.

6.

Spray lubricant around motor shaft to prevent

water from penetrating into the motor.

7.

Apply dielectric grease to all electrical connectors

between uses and for long term storage.

CAUTION

Do not attempt to install or remove spreader with material

in it.

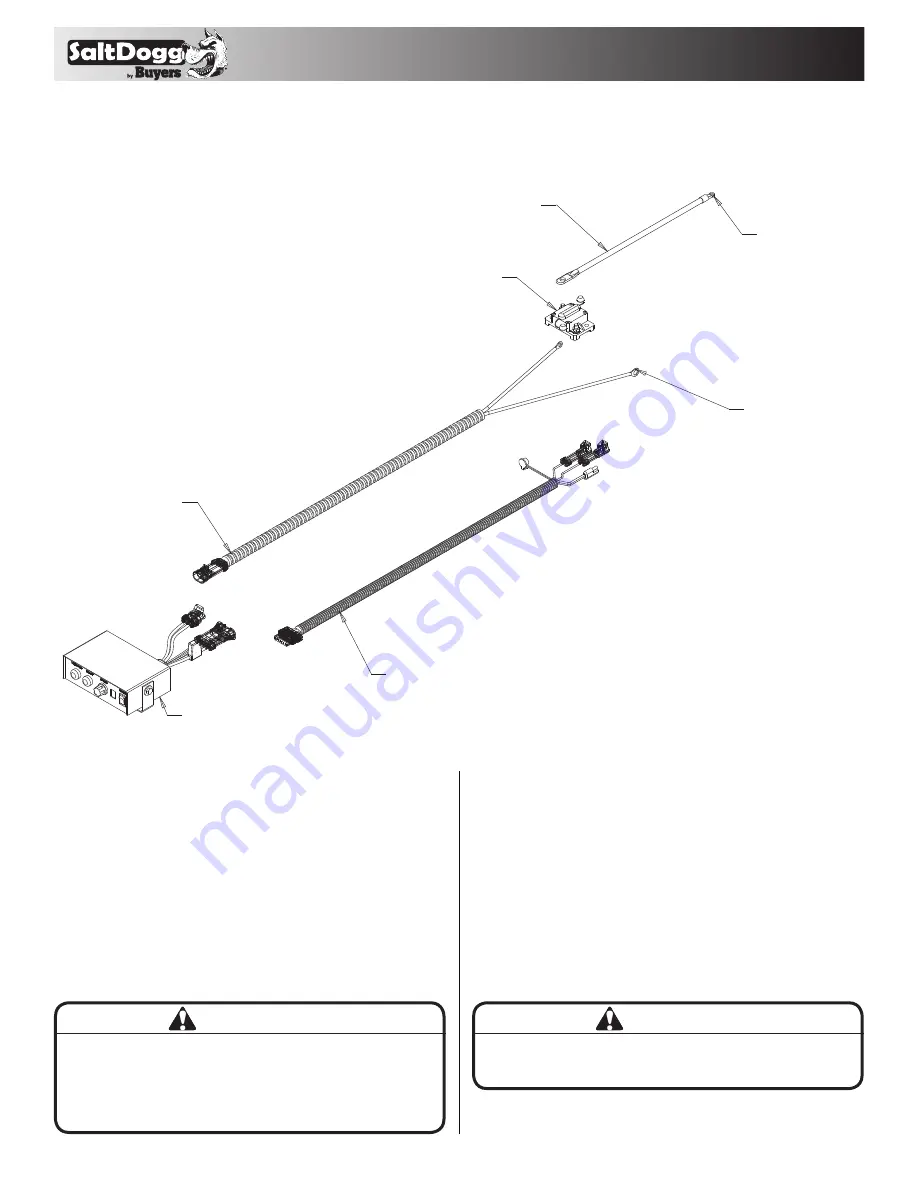

Fig. 2

Observe spinner direction of rotation. The correct

direction is counter clock wise when looking inside

hopper from the top. If direction is clock wise reverse

wires between Motor and Wire Harness.

Spreader Maintenance

1.

This spreader is designed to use loose free floating

materials such as #1 dry Rock Salt. Using different

grades and/or wet material will affect spreader

performance. Wet material can “bridge" and stop

floating onto spinner disk.

3011864

3008620

3035934

CB50PB

3001379

BATTERY POSITIVE

BATTERY NEGATIVE