4

1.

SAFE INSTALLATION AND USE

The controller is designed only for household

and similar use.

Before installation, service or maintenance

and prior to making any connections, always

disconnect power supply and make sure that the

terminals and electric wires are not energized.

When the controller is switched off using

keyboard, the controller terminals are still

under dangerous voltage.

Controller may be used only for its

intended purpose.

It is required to use auxiliary protection

automatics to protect hot water system (in

case of controller or software malfunction).

Programmable settings must be selected

suitably to your system type, taking into

account all of its operating conditions.

Wrongful settings may cause the collector

or reservoir malfunction (e.g. collector

overheating, etc.).

Programmed settings may be modified

only by a person who read and understood

this manual.

Use only in heating systems that are set

up in accordance with valid regulations.

Electric system to which the controller is

connected must be protected with a cut-

out device suitable for expected loads.

Never use the controller when its casing is

damaged.

In any case do not alter the controller

components.

The controller has micro-disconnection for

connected

devices

(operation

2.B

according to PN-EN 60730-1). It means

that at 230V voltage supply the pump

outlets have dangerous voltage, even if

the pumps are not controlled.

Do not allow children access to the

controller.

Before you open casing, first disconnect

power supply from the unit.

The controller must be installed in

accordance to the requirements of EN

60335-1 standard, by qualified and

authorized technician.

Do not install the unit when connected to

voltage.

Do not operate the unit when it is

malfunctioning or was repaired by

unauthorized persons.

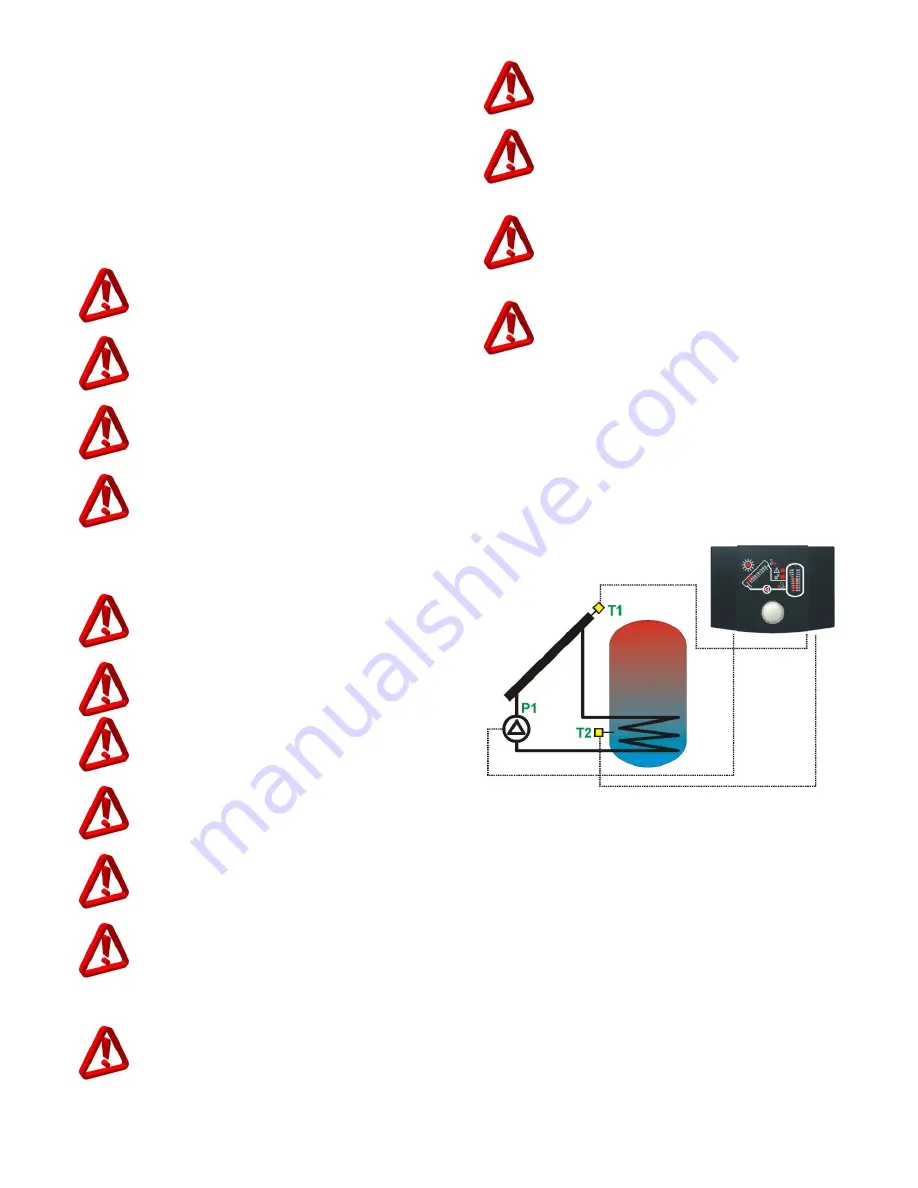

2.

GENERAL

PCSol 150 is an advanced electronic

temperature controller designed for heat

distribution from solar collectors to hot utility

water reservoir. The controller is used to control

solar circuit systems accordingly to indications

from temperature sensors to recover highest

possible energy from the collector.

Fig. 2.1 Functional diagram

Summary of Contents for PCSol 150

Page 2: ......

Page 6: ...6...

Page 7: ...OPERATING MANUAL PCSol 150...

Page 13: ...INSTALLATION MANUAL PCSol 150...

Page 22: ......

Page 23: ......

Page 24: ...SALUS Controls Made in Poland...