4

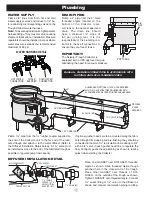

Plumbing

WATER

BLENDER

WATER HARNESS DETAIL

HOT WATER

CONNECTION

COLD WATER

CONNECTION

2" NPT DRAIN

AIR

GAP

WATER

BLENDER

WATER HARNESS DETAIL

HOT WATER

CONNECTION

COLD WATER

CONNECTION

2" NPT DRAIN

AIR

GAP

WATER SUPPLY

Plumb 3/4” lines from both hot and cold

water supply sources and reduce to 1/2” be-

fore attaching to corresponding valves on the

Trough Collector water harness.

Note: To assure against leaks, tighten water

harness fittings. They may come loose during

shipment, fabrication or installation. Pressure

regulators should be installed in areas where

water pressure exceeds the recommended

maximum of 80 psi.

DRAIN PIPING

Plumb a 2” pipe from the 2” male

threaded nipple located on the

bottom of the Collector reser-

voir tank to the nearest approved

drain. The drain line should

have a minimum 1/4” slope of

fall per running foot. It is the

responsibility of the plumbing con-

tractor to check all connections to

ensure they are free of leaks.

DIFFUSER INSTALLATION DETAIL

IMPORTANT!

The Salvajor Trough Collector is

equipped with a UPC approved air gap,

eliminating the need for vacuum breakers.

Plumb 1½” pipe from the 1½” rubber coupler supplied on

the end of the Collector unit to the far end of the fabri-

cated trough and attach it to the water diffuser (Refer to

the Diffuser Installation Detail below). A 1½” valve must

be installed as close to the end of the fabricated trough as

possible to regulate pump flow capacity.

If optional gusher heads are to be mounted along the fabri-

cated trough for scrapping and pre-flushing, they should be

connected to the main 1½” recirculation line reducing to 3/4”

with a 3/4” valve in each gusher head line to regulate the

flow. Configure gusher head plumbing as shown to reduce

splash when starting the Collector.

1

1

/

2

" FEMALE

THREAD to 1

1

/

2

"

SWEAT FITTING

ADAPTER (NF)

1

1

/

2

" UNION (NF)

#TVD3 GASKET

#TVD2 LOCKNUT

TROUGH SECTION

3”

MIN.

DIFFUSER #980061

Place one GASKET over DIFFUSER threaded

nipple as shown. Slide threaded nipple though

punched hole in the closed end of the trough.

Place other GASKET over threads of DIF-

FUSER, on the outside of the trough as shown.

Tighten LOCKNUT onto threaded nipple. Connect

1½” sweat fitting or 1½” union to the diffuser as

shown and connect recirculation piping to fitting.

GUSHER HEAD (OPTIONAL) 1-5/16” HOLE REQUIRED.

ALLOW 3 TO 4 FEET BETWEEN GUSHER HEADS TO

ACCOMMODATE ONE OPERATOR PER GUSHER HEAD.

DIFFUSER

2” HOLE

REQUIRED

3/4” VALVE (NF)

3/4” PIPING (NF)

1-1/2” VALVE (NF)

1-1/2” PIPING (NF)

45°

MAKE ALL PLUMBING CONNECTIONS IN ACCORDANCE WITH

NATIONAL AND LOCAL PLUMBING CODES.