REVISED 5/19/2017

© SAM CARBIS SOLUTIONS GROUP, LLC, 2017, WITH ALL RIGHTS RESERVED

PAGE 18

iii)

TRACK AND CARRIAGE OPTION WITH TCG-S910.1 TRACK LOCK MECHANISM

For existing platforms, use customer-supplied hardware to mount the tracks to the platform.

For Carbis-supplied platforms, Carbis will drill the bolt holes and supply the hardware for mounting the

tracks.

Install the track and carriage per the following sequence. For Carbis-supplied platforms with built-in

tracks, skip steps (1) and (2):

(1)

Bolt track section(s) to platform.

(2)

Tighten track mounting bolts only after all track sections have been installed.

(3)

Insert track stop components at one end of the track run.

(4)

Slide gangway into the track section.

(5)

Insert track stop components at opposite end of the track run.

(6)

With the gangway locked in the upright stored position, push the manual track lock lever down to

engage the brake to prevent the gangway from free-rolling along the track.

(7)

Disengage the chains from holding the gangway in the stored position, and reposition the chains

with the next to the last link engaged in the slot of the chain lock to begin operation.

(8)

For retrofit of the TCG-S910.1 Track Lock Mechanism on an existing gangway, see section

7)

MAINTENANCE

for the installation procedure.

iv)

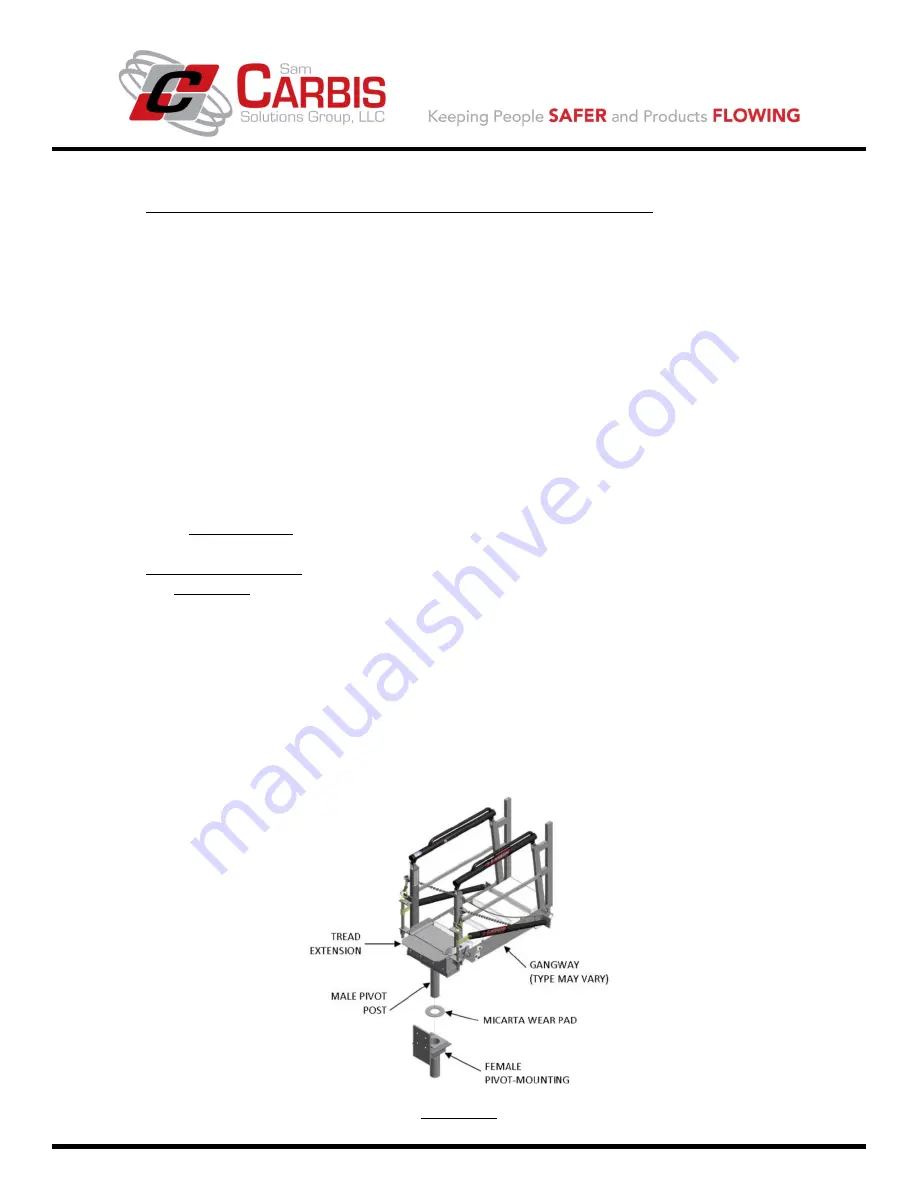

PIVOT MOUNT OPTION

See

FIGURE 5-1

below.

If Carbis supplies the platform for pivot-mounted gangways, then Carbis will supply the mounting

hardware; otherwise, use customer-supplied hardware to install the pivot mount per the following

sequence:

(1)

Attach the pivot mount receiver sleeve support component (face mounted or underslung mounted)

to the platform structure.

(2)

Install the wear pad on the top of the sleeve opening.

(3)

Insert the base tread pivot post into the sleeve.

(4)

Disengage the chains from holding the gangway in the stored position, and reposition the chains

with the next to the last link engaged in the slot of the chain lock to begin operation.

FIGURE 5-1