Instruction manual

Fodder wagons OptiFEED

14

Fodder’s quality depends on adequate sharpening of auger’s blades. In order to keep

fodder’s quality high, avoid overloading the tractor and the wagon during the work, increase its

longevity and reduce fuel consumption, check auger’s blades sharpness once a month. Damaged

blades should be replaced as soon as possible. Blades on the auger are not subject to warranty.

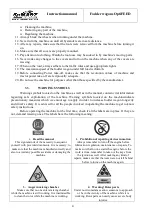

WARNING!

SCREWS AND NUTS MUST BE TIGHTENED AFTER FEW HOURS

OF NEW MACHINE’S WORK. THIS PROCEDURE SHOULD BE

USED AFTER EACH REPAIR AND INTERIM REVIEWS – AT

LEAST ONCE A MONTH.

Tightening torques for nuts and bolts MA

8.5.

CLEANING

Never use high pressure water to clean parts of weighing system. Remember to remove

remaining of the fodder containing grain seeds enriched with caustic soda that is located on the

external parts of the machine. After cleaning the machine with pressurized water, make sure that it

did not get to the oil.

8.6.

LUBRICATING

Make sure that the machine was properly lubricated before turning it on.

Lubricant type: High quality universal lubricant.

PTO should be lubricated once a week. Pay attention to PTO’s profile sliding tubes. They

must be able to perform longitudinal moves, even at high torques. Failing to lubricate profile pipes

will result in great increase of axial force which in turn may damage the power take-off and other

transmission shafts.