Instruction manual

Fodder wagons OptiFEED

18

After making adjustments to distributor’s lines, lock the nuts again. It is important to

periodically check distributor’s lines proper adjustments on your own.

8.9.

OIL LEVEL IN THE GEARBOX

Every week oil level in the gearbox should be checked. It should oscillate between signs

MIN and MAX.

Change the oil every 6 months. Make sure there is no water in the oil.

Oil used by manufacturer: Gearbox oil F-15.

8.10.

REPAIRS: WELDING

Under no circumstances should the electric current flow through parts of weighing control

system. Open the box; disconnect wires of weight control system and sensor cords. Moreover,

welder clamps should be placed in the near vicinity of the welded place.

8.11.

STRUCTURAL CHANGES

No kind of structural changes should be made in OptiFEED fodder wagon without prior

arrangement with the manufacturer. Manufacturer is not responsible for damages, breakdowns, or

improper functioning caused by structural changes made.

8.12.

ELECTRONIC CONTROL *

*

Applies to mixer feeders equipped with optional electronic control.

Electronic control for mixer feeder OptiFEED is offered as optional equipment. Regardless

of the model and size, each mixer feeder can have electronic control to facilitate and improve the

machine control while preparing a uniform feed mix.

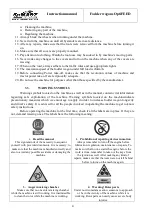

Controlling individual stages in the operation of the mixer feeder equipped with optional

electronic control is done by means of a clear-view control panel. The control panel also has push-

buttons with markings showing their corresponding functions.

Fig. 16. Electronic control panel for mixer feeder