16

FISHER

HYDRAULIC FRONT-LOADER EXTENSION ARM

OPERATOR'S MANUAL

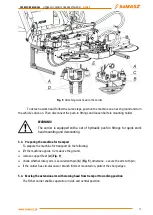

After having mounted the carrier, connect hydraulic hoses (

A

) for side shift and tooling rotation

supply and hoses (

B

) for work head supply (PT circular saw, PG branch grinder) (

). Remember to

adjust oil flow rate [L/min] to work head's demand

–

see Tab. 1.

WARNING!

If FISHER is aggregated with PT circular saw, the motor of which has no third oil

separation pipe, then the return hose (B - female connector) must be connected

to a connector on a vehicle with pressure-less return line. Otherwise hydraulic

motor can be damaged.

If the vehicle has no hydraulic connector with pressure-less return line, refer to

the instruction manual, or consult the vehicle's manufacturer where pressure-

less return line can be connected to the tank.

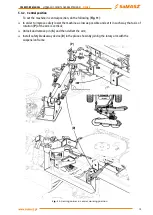

Depending on the type of vehicle, with which the carrier is aggregated, it is allowable to replace

connectors or extend hydraulic hoses on the user's own. If the oil flow rate is not adequate, SaMASZ

offers ZH hydraulic power pack to be mounted on the rear 3-point linkage, Cat. II with maximum flow of

130L/min

–

pressure 200bar.

WARNING!

Extending or using too thin hydraulic hoses for work head supply can lead to

overheating the pack, improper operation of the tooling attached or its damage.

Connect 3-pin controller plug (

C

) to corresponding socket on the machine, and lighter outlet (

D

)

to 12V cigarette outlet.

WARNING!

When connecting hydraulic hoses and electric cables to front loader's arms, in

machine rotation points, provide and leave some allowance, so that during the

operation they are not damaged.

5.2.

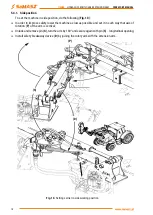

Attaching work head to the carrier

The Fisher carrier enables aggregation of the following work heads: PG 150, PG 200, PT3-190, PT4-

250. To attach a work head to the carrier:

❑

position the vehicle and the carrier set, so that the holder with mounting plate (Fig. 2,

item 6

)

overlaps the head's plate;

❑

using six M14 bolt connections (

B

) joint the two plates together. Tighten the bolts with torque

corresponding to their property classes (

). Central M30 bolt connection (

C

) is not required,

howev

er it facilitates the head rotation by 180°, if needed;

❑

connect hydraulic connectors (

D

) and secure the hoses by clipping them with chain (

E

) (