19

OPERATOR'S MANUAL

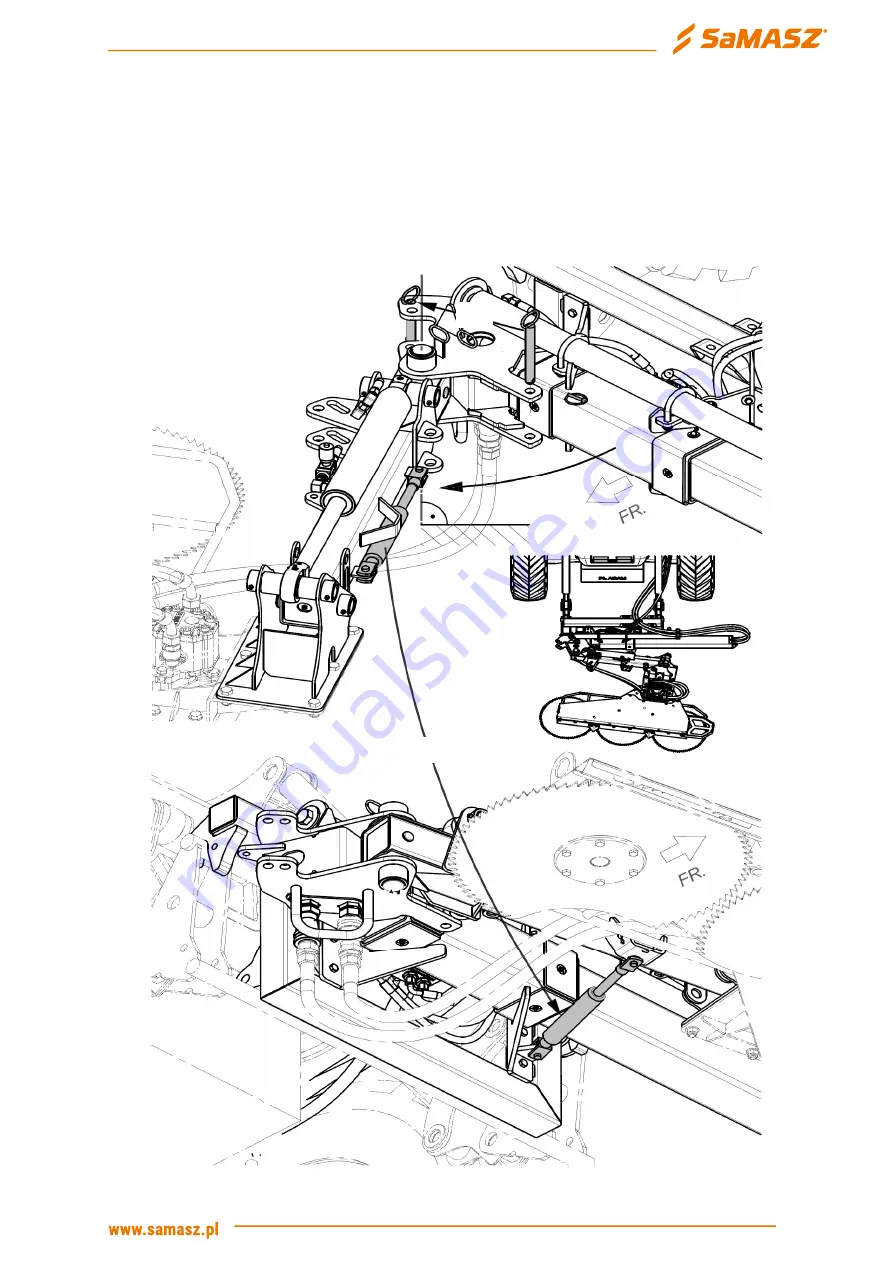

HYDRAULIC FRONT-LOADER EXTENSION

ARM

FISHER

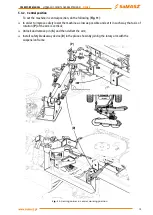

5.4.2.

Central position

To set the machine in central position, do the following (

❑

In order to improve safety lower the machine as low as possible and set it in such way that axis of

rotation (

P

) of the arm is vertical;

❑

Unlock and remove pin (

S

), and then deflect the arm;

❑

Install safety breakaway device (

D

) in the place shown by joining the rotary arm with the

suspension frame.

Fig. 11.

Setting carrier in central working position

(S)

(D)

(P)