Instruction manual

Rear - front and rear flail mowers

MIDO, GRINO, VINO, MAMUT

-

6

-

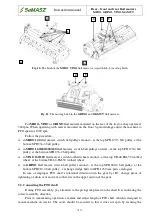

Fig. 2.

Overview of the mower

1 – Suspension frame

2 – PTO shaft

3 – Driving shaft

4 – Runner

5 – Belt gear

6 – Angle gear

7 – Guards

8 – Plate

9 – Cleaning plate (re: VINO)

10 – Counter knife (re: VINO)

11 – Copying shaft

12 – Flail shaft

13 – Flail blade

14 – Steel skid

3.3. Equipment and spare parts

The mowers are sold with the following standard equipment:

warranty card,

instruction manual along with a catalogue of spare parts and Declaration of Conformity,

additional set of flail blades,

hardened sliding skids,

protective metal sheet guards,

telescoping articulated shaft,

spray paint (150 ml).

Additional equipment (purchased separately):

additional set of flail blades,

additional set of bearings for the coping and working shafts,

additional set of seals for the bearings of the coping and working shafts,

protective chains – re:

MIDO

,

GRINO, MAMUT

hitch with hydraulic movement – one-sided or double-sided – re: MIDO, VINO,

additional row of counter cutters – re: MIDO, MAMUT,

LED warning plate - re:

MAMUT

,

mechanical suspension lock

–

re:

VINO, MIDO,

relief – re

MAMUT.

WARNING!

Optional extra equipment should be ordered separately.

1

2

5

6

7

14

4

8

9

10

11

13 12

3