Operator’s manual

Double-sided mower with central

suspension

“REWERS”

- 41 -

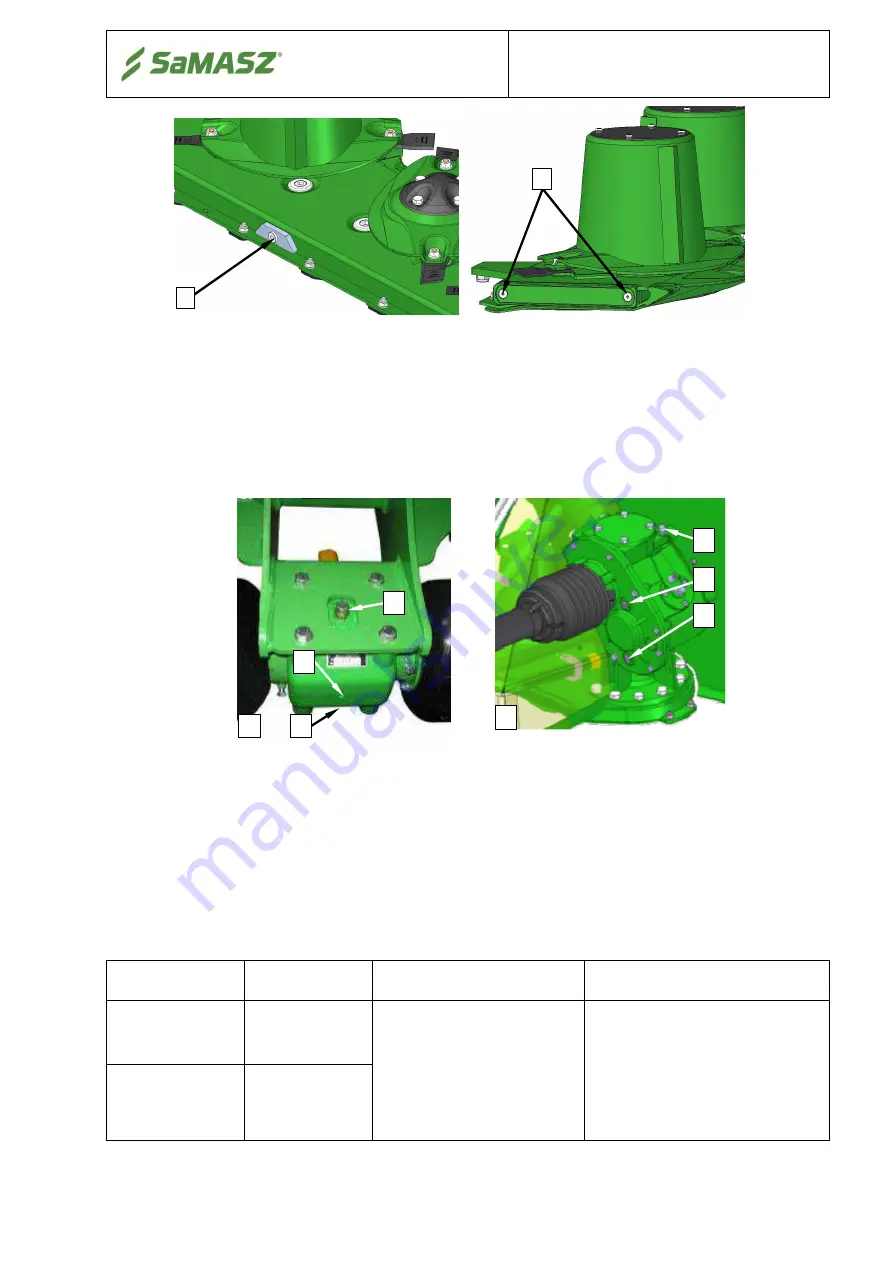

Fig. 38.

Points of oil inspection and replacement in cutterbar

7.3.

Intersecting axis gears

Everyday before starting work please check the oil level and, if needed, please refill after

having removed the vent

A

on the top of the gear (

Fig. 39

). The oil level can be checked through

check opening

B

on the side of the gear. Please refill the oil until it is visible in the check opening

B

. The oil capacity: about 1 liter. Check oil level when the cutterbar is on the ground. Removing

the worked oil from the gearbox is done through the outlet

C

.

Fig. 39.

Intersecting axis gears oil

To replace oil in gears:

Prepare an adequate tank for waste oil to be disposed of at a specialized plant,

Open refill vent

B

and drain vent

A

(

Fig. 39

),

Drain oils from the gear by opening drain vent

C

,

Close drain vent

C

,

Refill the oil level until it is visible in the check opening

B

,

Close refill vent

A

.

Tab. 6.

Oil capacities in intersecting axis gears

Model

Oil capacity

[l]

Oil type

Orrication frequency

All type

1

SAE 80W/90, API GL-4

After first 50 h of operation, then

after next 500 h

(or at least once a

year)

KDDR S/SL

Przekładnie:

052-02.0100AB.L

053-02.0100AB.L

2,5

a)

b)

A

B

A

B

C

C

B

A