Operator’s manual

Double-sided mower with central

suspension

“REWERS”

- 43 -

8.

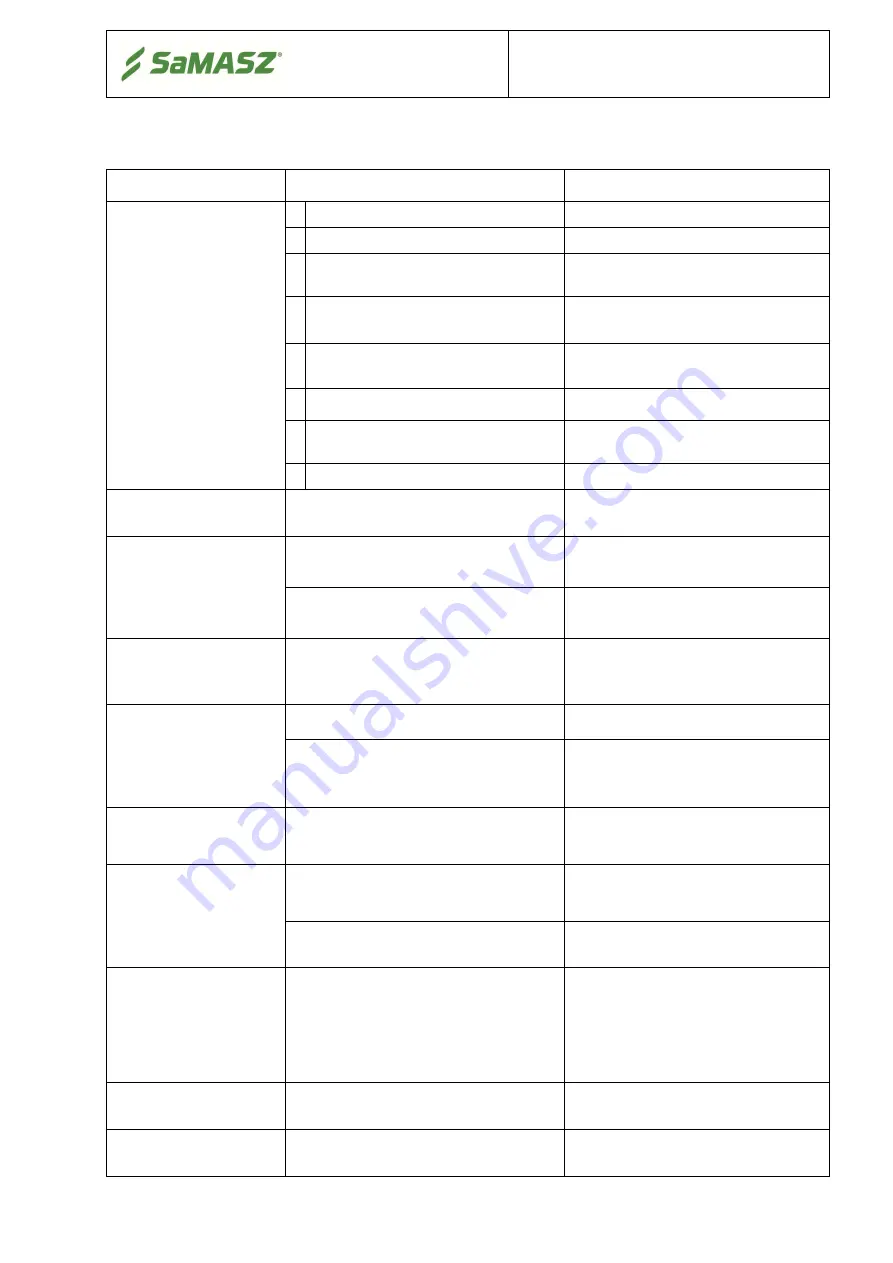

DEFECTS AND THEIR REPAIRS

Tab. 7.

Defects and their repairs

Defect

Reason

Repair

Mower stops working

(partly)– leaves stripes of

uncut grass between the

discs

1

Lack of knives

Put on knives

2

Worn knives

Replace knives

3

Improperly mounted knives

(left – right)

Put on knives strictly acc. to

instructions

4

Improper front inclination

Adjust inclination strictly acc. to

instructions

5

Too high PTO rpm

(The most frequent mistake)

Reduce PTO rpm

6

Too low work speed

Speed up to V

≥

10 km/h

7

Damaged tractor’s PTO

Repair

8

Lying grass

The inclination - the angle zero

The grass is wound on

the forming drums

Mowing lying grass without inclination

towards the front

Always mow low and fast –

inclination towards the front – 4 cm

Mower is blocked with

grass – no grass guiding

or guiding is uneven

Too low mowing speed

Increase the speed up to approx. 10

km/h or more

Swath guides are spaced too narrow

Space swath guides to their maximum

Safety device is working

often without clear

reason

Worn elements of safety device or

improper regulation

This repair must be done by SaMASZ

service

Mower is not mowing

even though drive is

transmitted from tractor

Damaged gear

Replace gear

Spline shafts – wrong rotational

direction of overrunning clutch

Check rotational direction

Mower is blocked

Damaged gears in the cutterbar.

Damaged bearings in the disc hub

This repair must be done by SaMASZ

service

Mower’s hydraulics does

not work

Damaged or dirty hydraulic cylinder

and check valve

Replace or clean hydraulic connector

and check valve

Tractor’s hydraulic system is damaged.

Check tractor’s hydraulic system

Leaking cylinder

Dirty oil in hydraulic unit of the tractor

Replace oil in hydraulic unit of the

tractor (recommended class of

cleanliness of oil according to NAS

1638 is minimum 9-10).

Purchase repair kit of the cylinder and

replace damaged sealings

Excesive vibration

during work

Damaged PTO shaft

Check the condition of PTO shaft and

if need be replace

Oil leak in gear

Not tight assembly

Examine tightness and check oil level