43

OPERATOR’S MANUAL

REAR DISC MOWER

KDT

7.3.

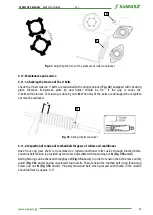

Roller conditioner’s gearbox

Before you check the lubrication of the gearbox, please remove the safety guard. Everyday before

starting work please check the oil level and, if needed, please refill after having removed the vent

A

on

the top of the gearbox (

) The oil level can be checked through the check opening

B

on the side

of the gear. Please refill the oil until it is visible in the check opening

B

. The oil level: about 0.13 US gal

lqd. Check oil level when the cutterbar is on the ground. Removing the worked oil from the gearbox is

done through the outlet

C

.

Tab. 8.

Oil capacities

Fig. 38.

Roller conditioner’s gearbox lubrication points

7.4.

Lubrication points

Every 50 mower working hours

lubricate tine/roller conditioner’s bearings (

) with

LT43

grease (or other designed to lubricate rolling and slide bearings, that work in -30

o

C do+130

o

C) and main

joints of the mower (

) with

STP

grease.

Fig. 39.

Bearing lubrication point with LT43 grease in roller conditioner

Model

Oil capacity

[US gal lqd]

Oil type

–

for gearboxes

Lubrication frequency

All models

0.13

80W90

After first 50 h of operation and then after

next 500 h (or at least once a year)

Lubrication

points

A

B

C