Operating manual

Rear disc mowers with central suspension

- with hydro-pneumatic or spring suspension

- 2 2 -

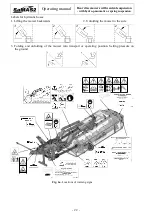

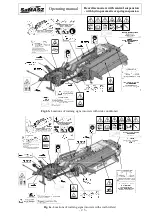

Labels for hydraulic hoses:

1. Lifting the mower backwards

2. Unfolding the mower to the side

3. Folding and unfolding of the mower into transport or operating position. Setting pressure on

the ground.

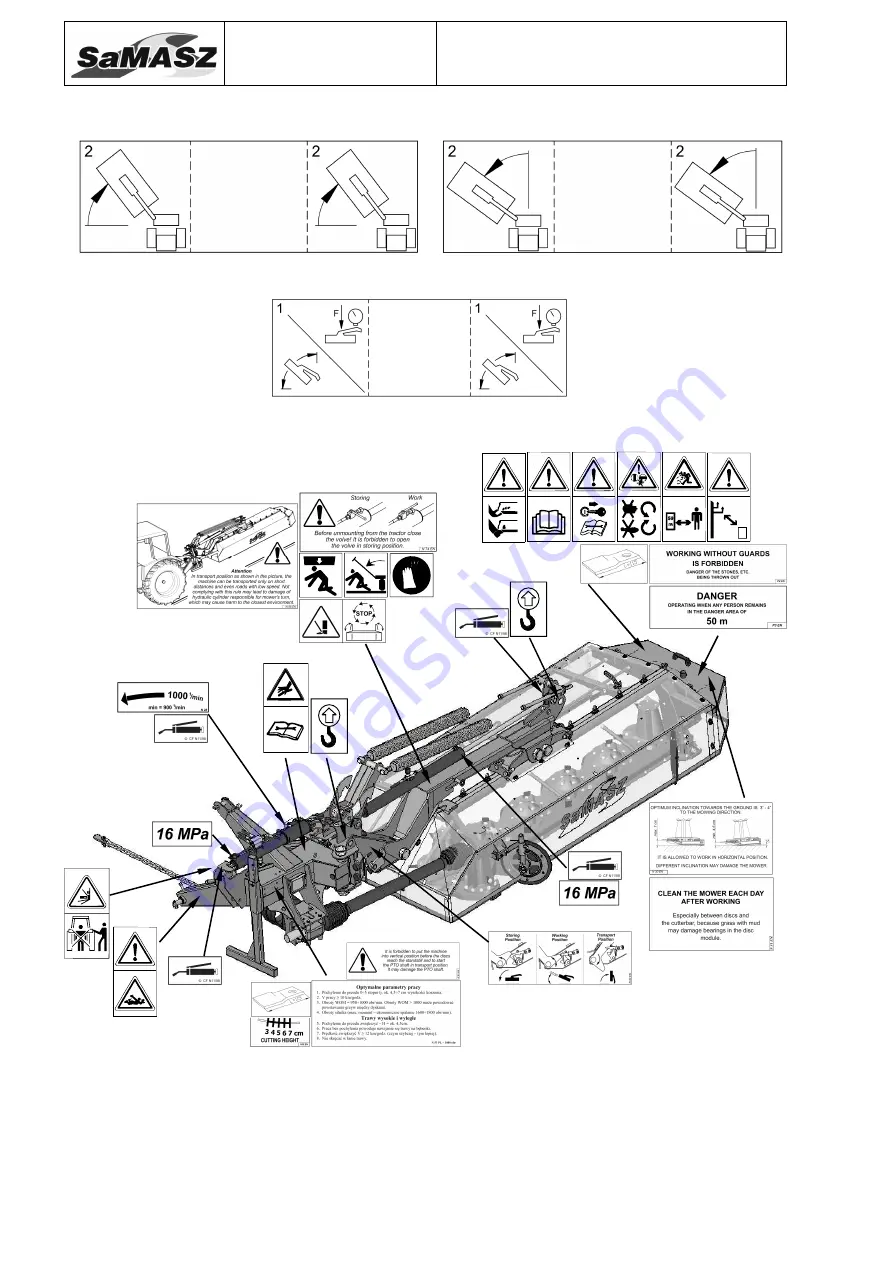

Fig. 6a. Locations of warning signs