Operator's manual

Arm

Flail head

- 48 -

6.5.

Operating hydraulics

Condition of hoses and hydraulic fittings should be examined periodically and in case of

finding damages replaced with new ones. Irrespective of the above hydraulic hoses should be

replaced with new ones every 5 years taking their storing period into consideration. In winter idle

period it is recommended to store the machine in dry, well vented room, paying attention

the hydraulic hoses are not deflected.

CAUTION:

Oil used in hydraulic circuits is toxic. Prior to performing any servicing,

oil replacement, the operator should wear protective clothing.

Strictly follow the binding provisions on hazardous waste. Used oils

should be drained to special containers and then taken to

a nearby oil

treatment plant

6.5.1.

Oil tank with equipment

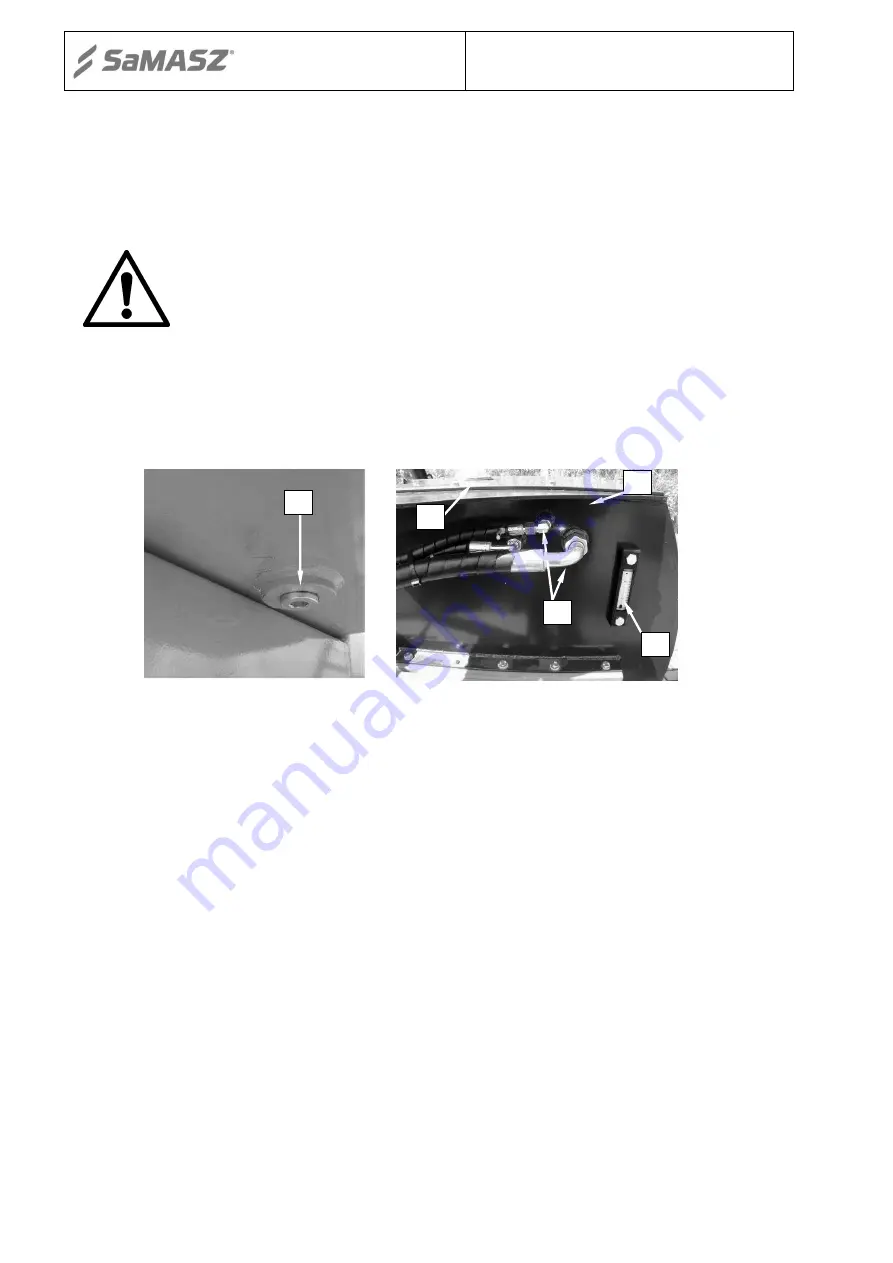

Tightness of tank's (9) welded joints should be examined as well as hoses connections. These

activities should be performed at least once a month (Fig. 58).

Fig. 58. Oil tank

Potential leaks shall be welded after the oil is drained. Drain plug (45) is located underneath the

tank (9). Damaged paintwork should be repainted and oil loss supplemented with HYDRAULIC

PREMIUM 46 HV oil group oil with similar properties. The tank holds approx. 150 l of oil – Koliber

400/450, 220 l of oil – Camel 900 and KWT 550/650/651. Refilling oil should be performed through

upper air vent filter (46). In order to perform this "can" should be dismounted from the tank, and only

special sieve shall remain inside, which collects impurities contained in oil. Oil level is indicated by

indicator plug, which should be unscrewed when oil is filled into the tank. Upon obtaining proper oil

level all plugs and filter should be tightened. Above the indicator plug there are hydraulic hoses

nozzles

–

tank fills (48).

The oil must conform with purity class: 15÷18 in conformity with ISO 4406, 9 in conformity

with standard NAS 1638. If the oil does not conform with the provided purity class then replace it. If

the oil purity is doubtful then it should undergo a purity test in corresponding testing authority.

6.5.2.

Oil shut-off valve

Tightness of joint connections at valve (49) should be controlled at least once a day. Leaks

should be removed by tightening nuts and /or band clips (50) (Fig. 59).

Open position

–

lifting set along feeding hydraulic hoses (ON).

Close position

–

lifting set perpendicular to feeding hydraulic hoses (OFF).

45

47

48

46

9