7

OPERATOR’S MANUAL

TRAILED ROTARY TEDDER

P10-1200

3.3.

Standard equipment and spare parts

The tedders are sold with the following standard equipment

:

❑

warranty card,

❑

operator’s manual with spar

e parts list and Declaration of Conformity,

❑

PTO shaft,

❑

slow travelling vehicle board,

❑

spray paint (150 ml).

Tab. 2.

Recommended PTO shafts for rotary tedders

Model

Power

Length

Moment

Symbol

Clutch

Manufacturer

KM

mm

Nm

P10-1200

21

1210-1733

270

8G5T085CE007001

friction

Bondioli & Pavesi

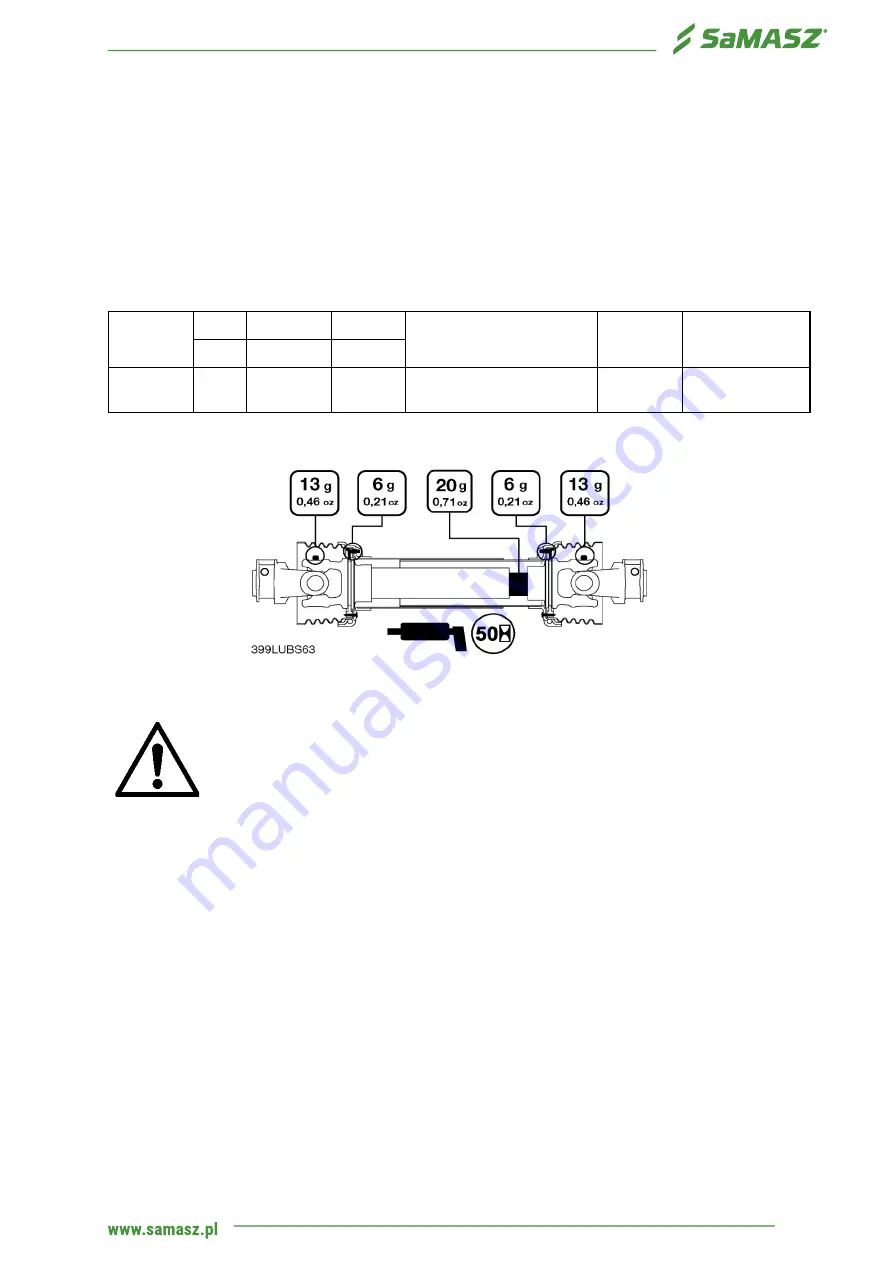

Fig. 4.

PTO shaft lubrication points

WARNING!

The frequency of lubrication of the articulated telescoping shaft should be

carefully adhered to. Points shown in

should be lubricated every 50 hours.

The articulated telescoping shaft should also be lubricated before and after

longer periods of disuse

.

PTO shafts of other brands with equivalent parameters could be used after SaMASZ permission.

4.

SAFETY ADVICE

4.1.

Safety rules and regulations

❑

Operation without safety guards as well as with the damaged guards is not allowed.

❑

Start tedding only when the tractor’s PTO reaches its nominal rpm

.

❑

Nobody is allowed to remain within the danger area of at least 50 m. Particular caution is necessary

when operating near roads and in stoney areas.

❑

Any maintenance and adjustment work should only be done after the drive has been disconnected

and the rotors are in standstill.

❑

When driving on public roads always comply with local traffic regulations, especially concerning

warning lights.

PTO shaft’s end without clutch

–

To be mounted on the

tractor’s side

PTO shaft’s end with

friction clutch

–

To be

mounted on tedder’s side