Operating manual

Tractor mounted snow plow

Smart (K), Lite 150, Uni

-

8

-

The

Smart

plows have been designed so that there remains a possibility to mount them on

the small municipal tractors, which because of the special construction of the front three point

hitch (TPH) cannot accept mounts of the cat. I TUZ type (mounting pin distance

683 mm

).

The municipal mounting system

(mounting pin distance

400 mm

) has been designed for

the purpose of replacing the standard mounting system (

Fig. 5

).

Fig. 5.

The

Smart 150 K

plow (with the municipal mounting system)

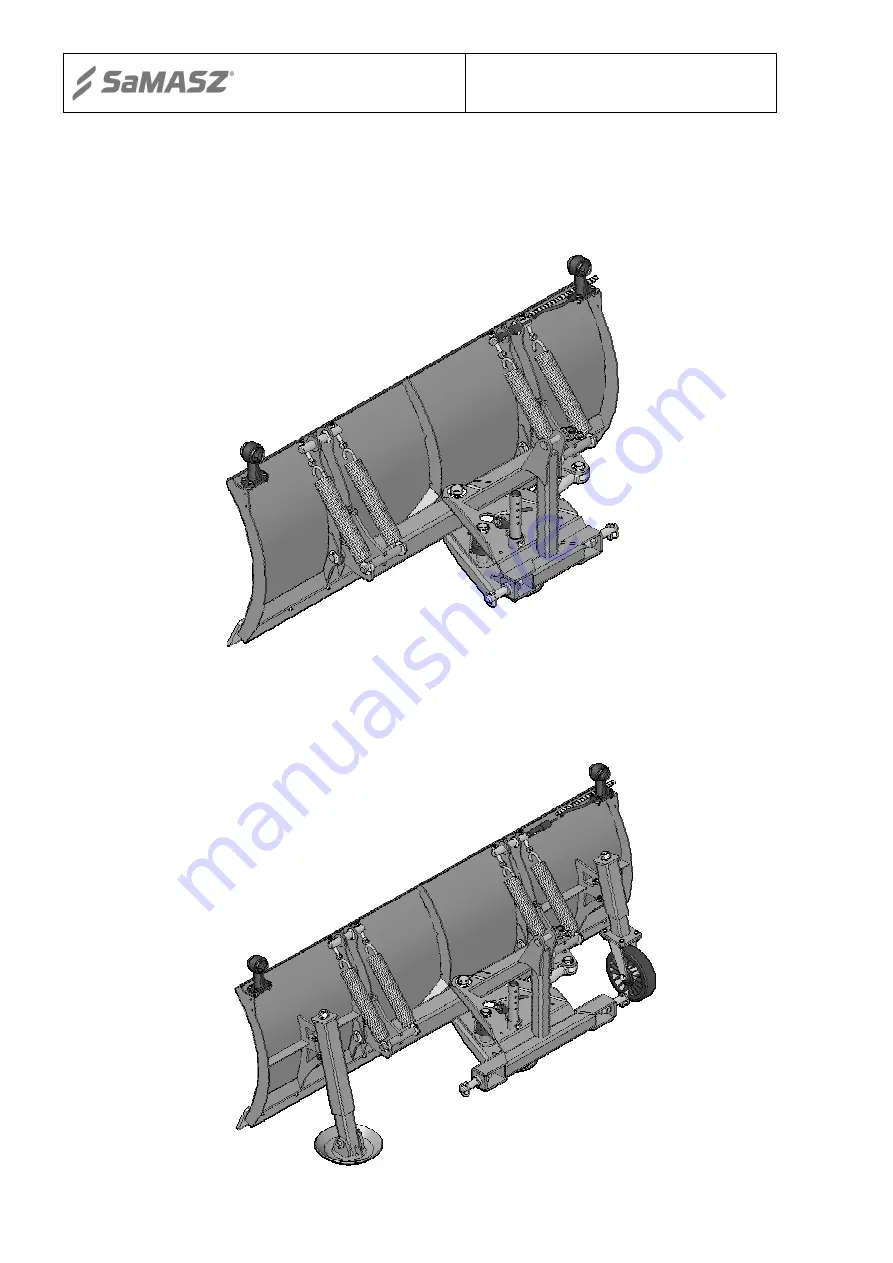

Additionally as optional equipment for the

Smart 180 (K)

plow support wheels or skids

may be purchased, reducing the pressure of the plow on the ground which extends the life span of

the rubber blade inserts or the metal blade inserts (

Fig. 6

).

Fig. 6.

The

Smart 180

plow with the support wheel and support skid installed