Operating manual

Tractor mounted snow plow

Smart (K), Lite 150, Uni

-

18

-

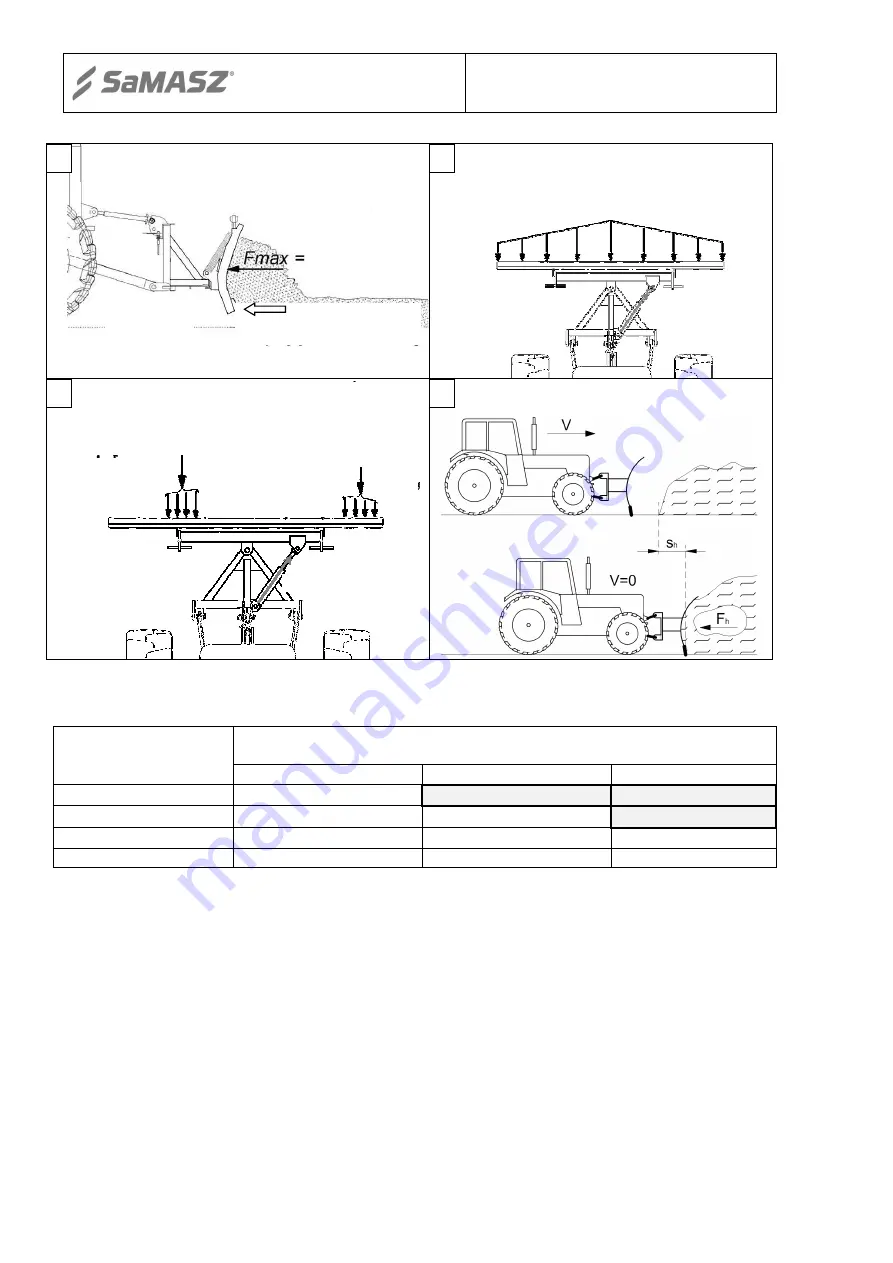

Tab. 4.

Schematic visualization of the permissible loading of the Smart plow

Tab. 5.

Approximate force

F

h

acting on the plow, at speed

V

and stopping distance

S

h

with a tractor weight

equal to 3 tons – according to Tab. 4d

Braking distance

S

h

= [cm]

Estimated head force

F

h

= [T], for braking of tractor with mounted plow at

speeds

V

.

5 km/h

10 km/h

20 km/h

10 cm

1

11

16

20 cm

0,5

3

8

30 cm

0,3

1,2

3

40 cm

0,2

0,5

2

The table above is a demonstration to show the operator how suddenly the forces change

depending on speed and stopping distance.

The initial force under which the moldboard starts to tilt depends on the initial spring

setting. The initial spring setting can be adjusted in the range of

0

to approximately

60 mm

using

the four tension bolts located in the upper part of the moldboard. As evident in

Tab. 6

this force is

not constant as the moldboard tilts but rather changes unevenly. The table above shows the

working of the blade with the initial spring setting at

30 mm

. The greatest resistance force

Fu

is

created in the moldboard between tilt angles of

35

o

and

45

o

from starting position. By increasing

the initial spring setting the

Fu

is also increased along with the pressure on the entire plow, which

can lead to damage of the plow especially with greater operating speeds. If the initial spring

setting is high then great care should be taken to maintain low plowing speed, since in the event of

encountering an obstacle this will allow the operator to quickly stop the tractor.

Lateral coping is achieved thanks to the oval, vertical openings in the mountings of the front

TPH of municipal tractors. If the front TPH is not equipped with this solution then care should be

taken during plowing, especially on uneven terrain.

a)

Schematic of the permissible loads

affecting the Smart plows

up to 3 tons

Ground

Fu - Force tilting

the blade

Distribution of permissible loads of the Smart

plows with SJ2F-50-28x200

actuator - up to 3 tons

F=3 tons

Schematic of the permissible loads of the

Smart plows

Option 1

Option2

F=3 tons

up to 1500 kg

Fmax up to

800 kg

b)

c)

d)