11

OPERATOR’S MANUAL

ROTARY RAKE

UNO

❑

Possible inclination of the shaft depends on shape and size of the guard. Before operation check if

guards in any position are not damaged or locked.

❑

Always pay attention to the recommended overlap of the PTO shafts in working and transport

positions.

❑

Before you start work, you must make sure that the PTO shaft is spinning in the right direction and

that the tractor PTO RPM matches the permissible RPM levels of the machine.

❑

When using the power PTO shaft there must be nobody in the danger zone of the rotating telescopic

joint shaft or PTO shaft.

4.7.

Hydraulic assembly

❑

Caution! Hydraulic assembly is under pressure! Hydraulic oil under pressure may penetrate skin and

cause serious injury. Skin and eyes should be protected in particular. In case of injuries caused by

a liquid under pressure, call a doctor immediately.

❑

Hydraulic hoses can be connected to the tractor's hydraulics provided t

hat both the tractor’s and

the rake's hydraulic assemblies are not under pressure. To remove the pressure from the hoses,

start the tractor's hydraulic valves several times with the tractor off.

❑

When unmounting the machine from the tractor, set the equipment used aside, deflate the pressure

from hydraulics and turn the tractor's engine off.

❑

When inspecting the hydraulic assembly for malfunctions and oil leaks, do not touch any potential

leaks as the assembly is under pressure.

❑

Note! Use only hydraulic oil featuring oil purity class 9 - 10 in accordance with NAS 1638.

When using hydraulic hoses:

❑

Avoid stretching the hoses when operating.

❑

Do not allow hydraulic hoses to get deflected.

❑

Do not expose hydraulic hoses to contact with any sharp edges.

❑

If damaged or worn, replace the hoses with new ones.

❑

Useful life for hydraulic hoses is 5 years from their production date.

4.8.

Tires

❑

The air pressure in the wheels must be regularly checked and maintained at the appropriate level

recommended by the manufacturer.

❑

Repair work on the machine’s tyres and wheels may only be carried out by qualified personnel with

the appropriate tools for this type of work.

❑

When carrying out maintenance and repair work on tyres and wheels, ensure that the machine is

properly parked and secured against rolling away (use wedges).

❑

Disassembly and assembly of the wheels requires appropriate skills and equipment.

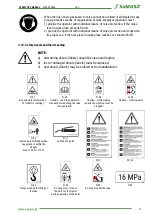

4.9.

Residual risk

Despite the fact, that SaMASZ company

–

the manufacturer of the rake takes the responsibility

for the rakes design and manufacturing, in order to eliminate hazard, certain risk when operating the

machine is unavoidable. When keeping such recommendations as:

❑

thorough familiarizing with operator’s manual,

❑

no persons remaining on the machine when operating and during drives,

❑

no persons remaining within the rake operation range,