9

OPERATOR’S MANUAL

ROTARY RAKE

UNO

4.2.

Qualifications of operator

To provide safe machine operation each person being the machine operator must meet the

following requirements:

❑

Operator should hold driving license, have ability to drive vehicles safely and know road traffic rules.

❑

Operator must be in proper physical condition to be able to operate the machine.

❑

Operator must not be under the influence of alcohol, drugs and medicines, which all have influence

on vehicle driving and machine operation.

❑

Operator should be familiarized with this manual and follow its provisions.

❑

Operator should be familiar with working principles of both the tractor and the machine, and be able

to recognize and avoid hazards resulting from operation of the aggregate.

4.3.

Conditions of mounting mower on tractor

❑

Prior to the mounting operation, check whether the tractor's and the mower's hitch categories are

compatible and make sure that tractor's hitch load is adequate for the machine aggregated.

❑

Prior to mounting the machine, examine technical condition of the mower's hitch assembly and

tractor's 3-point linkage.

❑

Use only genuine pins and cotters to mount the mower on a tractor.

❑

Once the machine is mounted on tractor check stability and manoeuvrability of the latter. Load on

the front axle should be approx. 20% of the weight of tractor. Otherwise, ballast front of the tractor.

4.4.

Transport

❑

Any modifications in the rake's position are possible only if no unauthorized personnel is around

(children in particular).

❑

When transported the rake shall have mobile warning light device and warning triangle mounted for

slow driving vehicle.

❑

When transported the rake should always be set in transport position. See chapter 5.2.

❑

Prior to putting the rake to transport position make sure, that the tractor PTO is disconnected and

all the rotating parts in complete standstill.

❑

Driving speed should always be adjusted to current road conditions.

❑

Driving speed should always be adjusted to current road conditions and traffic code applicable in

your country.

NOTE:

When transporting the rake on even road, do not drive faster than 25 km/h.

Whenever any unevenness is on the way, reduce the speed. Exceeding speed or

not adjusting it to road conditions may cause damage to the machine.

4.4.1.

Putting machines onto another vehicle for transport

Both the carrier and the driver shall be responsible for the rake transport safety. Any equipment

and parts must be secured properly for transport.

In order to have the rakes relocated safely onto another vehicle, please follow these rules:

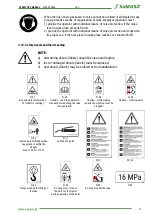

❑

The rake should be seized by any lifting device only in places indicated on the machine by the hook

sign.

❑

Transport belts, belt suspensions, ropes cannot be damaged. Whenever damages to these parts

are spotted replace these with new ones.