Operator’s manual

Twin-rotor rotary rake

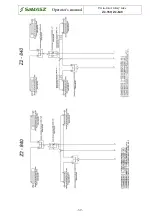

Z2-780; Z2-840

- 30 -

8.

LUBRICATION

8.1. Risks present when lubricating:

If risk of splashing is present, make sure to wear protective eyewear with side guards.

When lubricating protect eyes and skin against contact with the substance. Therefore use

adequate protective wear with long sleeves and protective footwear. Also use protective gloves.

In case of a contact with skin, immediately wash the infected area with plenty of water with

soap.

Do not allow the product to contaminate water outlets, water courses and soils.

In case of an unintentional release to the environment plug the leak, limit the spillage, and then

collect the oil with non-flammable absorbent material (e.g. sand).

The product is flammable. In case of fire, use adequate fire-extinguishing means (e.g. foam,

water mist, extinguishing powders). Do not use water jets.

Disposal of the used product must be made according to official regulations. Improper disposal

of the used oil poses danger to the environment.

8.2. Gearbox

Before daily work check the oil level and, if needed, refill. The oil level can be checked by the

check opening

B

(

Fig. 32

). Please refill the oil until it is visible in the check opening

B

. Vent

C

is

used for draining of oil.

To replace oil in gears:

Prepare an adequate tank for the used oil to be disposed,

Open fuel cap

A

and the drain plug

C

,

Drain oil from the gear,

Close drain plug

C

,

Refill the oil level until it is visible in the check opening

B

,

Close fuel cap

A

.

Fig. 32.

Lubrication points on gearbox

Tab. 6.

Oil capacities

Model

Oil capacity

Oil type

Z2-780

1.7 Gal US- Liquid for each one

SAE80W/90 API GL-4

Z2-840

2.2 Gal US- Liquid for each one

Every 50 hours of the rake’s operation, check lubrication points

D

and

E

on the gear

(

Fig. 33

) and apply grease

ŁT43

(or other lubricant designed for lubrication of rolling and sliding

bearings that are exposed to operating in the temperature range of -30°C and +130°C).

A

C

B