16

Vise

The following maintenance must be carried

out at adequate intervals in accordance with

operating conditions and frequency.

(1) Check the flatness of the bottom face of

vise so as to be free from damage and

dirt. Coat this face and upper face with

machine oil regularly.

(2) Clean vise and around.

(3) Clean T-shape slide way and clamp

screw. Coat them with high-pressure

grease. Optimal longtime PDI(Nippon

Perkerlizing Co.) is applied before

shipping.

작동조건이나 빈도에 따라 적절한 주기로 보수

점검 해 주십시오.

(1) 본체 상면이 이물질에 손상되지 않았는지

확인하시고 사용시 오일을 공급해 주십시오.

(2) 제품 및 주변을 청결하게 사용해 주십시오.

(3) 스크류바와 T-홈 부에는 고압용 그리스를

사용해 주십시오.

5. Maintenance

and inspection

5.

维修

5. 유지보수

0.010

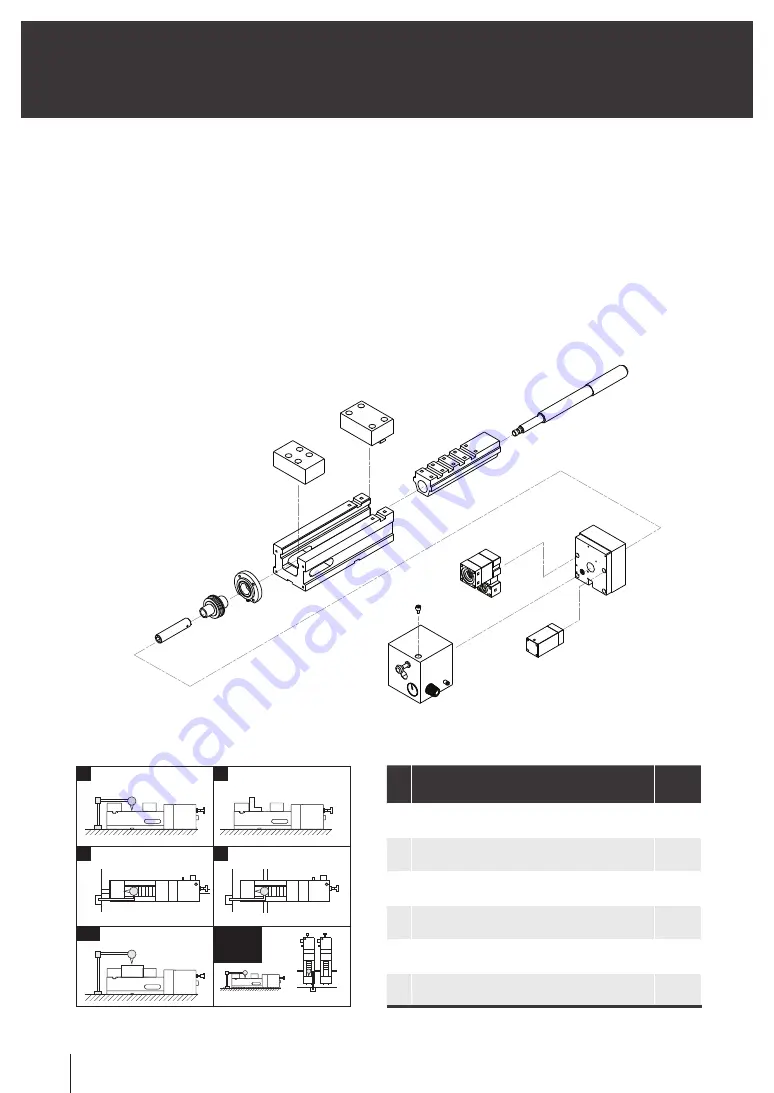

1

2

3

5, 6

4

병렬사양

Parallel use

并列规格

0.010

Fig.7

Fig.8

需要根据工作条件和频率,按适当周期定

期维修。

(1) 检查本体上面是否受异物损伤,然后

照样使用。

(2) 清洁虎钳和周围。

(3) 丝杠和T槽要使用高压用润滑油。

정도규격 / Accuracy standard /

精度规格

No.

검사항목

Inspection list

检查项目

허용치

Tolerance

允许值

1

몸체 밑면과 상면의 평행도

Parallelism between top and bottom face

本体底面与平行度

0.010

2

고정죠 및 이동죠와 몸체 상면과의 직각도

Squareness between jaws and top face

固定卡爪与移动卡爪跟本体上面的垂直度

0.010

3

몸체의 가이드 블록과 고정 죠와의 직각도

Squareness between guide block (key) and fixed jaw

本体的导块与固定卡爪的垂直度

0.015

4

몸체의 가이드 블록과 고정죠와의 평행도

Parallelism between guide block (key) and fixed jaw

本体的导块与固定卡爪的平行度

0.010

5

파악시 몸체와 테스트 블록과의 평행도

Parallelism between guide block (key) and body during

clamping

夹持时本体与测试块之间的平行度

0.015

6

파악시 몸체와의 테스트 블록과의 부상량

Lifting between body and test block during clamping

夹持时本体与测试块之间的浮上量

0.015

Summary of Contents for APV-125

Page 2: ......

Page 4: ...4 Vise 1 7 2 10 2 2 10 3 11 4 13 4 1 13 4 2 13 4 3 15 5 16 6 17 7 18 8 20 9 21...

Page 6: ...6 Vise 1 7 2 10 2 2 10 3 11 4 13 4 1 13 4 2 13 4 3 15 5 16 6 17 7 18 8 20 9 21...

Page 22: ...n o t e...

Page 23: ...n o t e...

Page 24: ...n o t e...

Page 25: ......

Page 26: ......

Page 27: ......