8

Special Chuck

Special Ch

uck

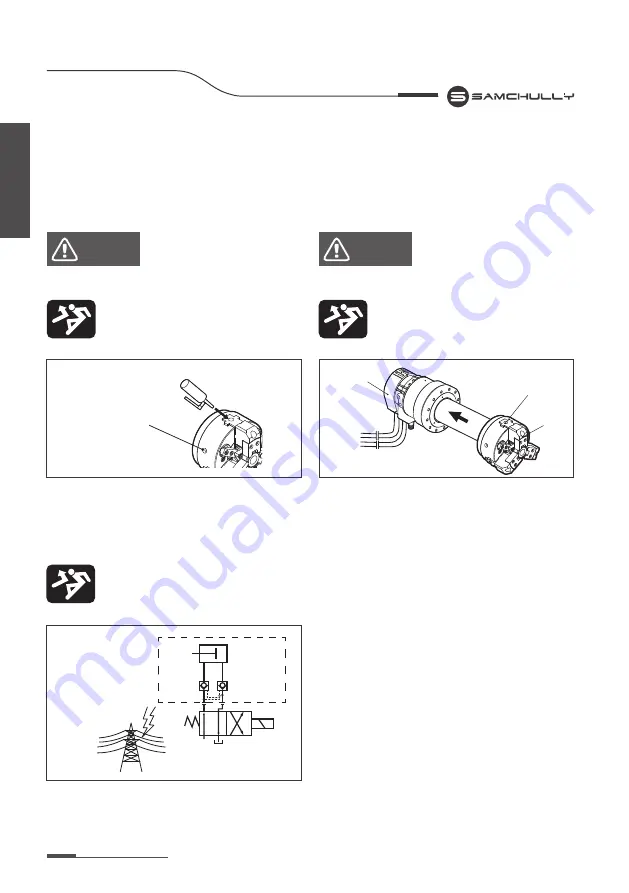

실린더 추력은 허용치 이내로 조절하여 주십시오.

Do not exceed Max. permissible input force

related with plunger input force.

请在允许值范围内调整气缸的推力。

윤활유 (그리스) 부족시 파악력이 저하되어 공작물 이탈 (비산) 위험이 있습니다.

Danger by discharge of workpiece related with lowering gripping force

caused by unsufficint lubrication.

启动液压不足时,夹持力会降低,加工产品有可能被用出 去(飞散) 的危险。

과다한 추력으로 실린더가 파손될 수 있습니다.

Excessive force may cause damage to the cylinder.

用力过大可能会导致损坏气缸。

조작 실린더는 로크밸브, 릴리프밸브 내장형 사용시 루프 솔레노이드 밸브를 정전시에도 파악하는 회로로 하십시오.

In cases of power failure Samchully Cylinders are fitted with check valves and pressure release valves. When

power is restored the solenoid valve resumes its normal function.

操作气缸是在使用带锁阔门、泄放阔内装型时请把电磁阔用于停电时夹持的电路。

Do not forget to grease chuck.

请准确地加油。

윤활은 확실히 행하여 주십시오.

낙뢰, 정전시에 파악된 공작물의 이탈 (비산) 위험이 있습니다.

파악 위치를 맞게 설정하십시오.

Gripped workpiece may discharge by lighting or interruption.

Set work to correct gripping position.

打雷、停电时夹持的加工产品有可能被用出去(飞散)的危险

o 请妥善设定夹持位置。

실린더

입력

척

죠

Cylinder

Input force

Chuck

Jaw

气缸

输入力

卡盘

爪

언클램프

실린더

클램프

Unclamp

Cylinder

Clamp

松开

气缸

夾持

솔레노이드 밸브

낙뢰, 정전

Solenoid valve

Lighting, Interruption

电磁阀

打雷, 停電

그리스 주입기

그리스 니플

Grease gun

Grease nipple

黄油枪

油嘴

WARNING

경 고

WARNING

警 告

Summary of Contents for PHD

Page 1: ...Special Chuck PHD PHDN Instruction Manual...

Page 31: ......