17

Instruction Manual

4. Precautions

4.

使用时的注意事项

4. 사용상의 주의

1. The serrations of master jaws and joints

of T-nut should be cleaned when replace

the top jaws, otherwise, it may cause

poor accuracy.

2. Set the air pressure according to the

shape of workpieces and cutting

conditions, the pipe-shaped workpieces

will be deformed due to the high pressure

clamping.

3. Do not use the master jaws which

serrations are deferent from the top jaws,

the insufficient engagement will affect

the gripping force and accuracy,

moreover, damage the master jaws.

4. Do not clamp the workpiece on the chuck

when stop the machine for a long time.

5. When the tool or tool holder impact the

chuck due to the improper operation or

malfunction, stop the machine

immediately to check the top jaws, master

jaws, T-nuts, mounting bolts and gripping

accuracy are at normal conditions.

6. When use the special height top jaws,

the air pressure should be lower than

when standard top jaws used.

7. Lubricating the chuck is very important,

bad lubrication will cause insufficient

gripping force and abnormal abrasion.

8. The max. pressure can not exceed the

standard max. pressure limit of chuck.

(refer to page.25)

!

WARNING

!

WARNING

警 告

RTC Chuck is ideal for using on the NC

rotary table with intermittent rotating; if use

in the continuous revolution, the heat of dis-

tributor may increase or it may breakdown

due to seized even under the set value.

!

WARNING

경 고

RTC척은 연속적으로 회전하지 않고 간간히 회

전하는 NC 로터리 테이블에 적합 합니다. 연속

적으로 회전할 경우 디스트리뷰터에 열이 증가

하여 회전부가 늘러붙어 디스트리뷰터가 파손

될 수 있습니다.

1. 마스터죠의 세레이션과 T-너트는 탑죠를

교환할때 깨끗해야 합니다. 그렇지 않으면

정밀도가 감소됩니다.

2. 가공물 형상과 절삭 조건에 따라 공기 압력

을 설정합니다. 파이프 형상의 가공물은

고압으로 파악하면 변형될 수 있습니다.

3. 세레이션이 맞지 않는 마스터죠와 탑죠를

사용하지 마십시오. 파악력과 정밀도가 감소

하며, 마스터 죠가 손상될 수 있습니다.

4. 기계를 장시간 사용하지 않을 경우 척에 가

공물을 고정해 놓지 마십시오.

5. 부적합한 작동이나 오작동 때문에 툴이나

툴 홀더가 척에 충격을 가할 경우 기계 작동

을 즉시 중단하고 탑죠, 마스터 죠, T-너트

체결볼트 및 체결정밀도가 정상인지 확인

합니다.

6. 특수한 높이의 탑죠를 사용할 경우 공압은

표준 탑죠를 사용할 때보다 낮아야 합니다.

7. 척의 윤활은 매우 중요합니다. 윤활이

불량할 경우 파악력이 불충분하게 이루어져

비정상적인 마모가 발생합니다.

8. 최대공압력을 초과하여 척을 사용하지

마십시오.(페이지 25 참조)

!

WARNING

!

WARNING

警 告

!

WARNING

경 고

죠 의 결합 위치에 대해 주의

척의 T-너트는 마스터 죠 보다 튀어나오지 않

은 상태에서 사용하십시오.(Fig.7 우측) T-너트

가 돌출된 상태(Fig.7 좌측) 에서 사용하면 마스

터 죠, T-너트가 파손되고 공작물의 이탈(비산)

의 위험이 있습니다.

注意夹爪的连接位置

使用时, 夹头的四爪钉不应突出于主爪.

(Fig.7图)

若在四爪钉突出的情况下使用,则主爪和

四爪钉会损坏,并加工产品有可能被用出

去 (飞散) 的危险.

RTC卡盘不适于连续转动而是间或转动的NC

转台。如果连续转动,Distributor 热量

增加,转动部分被粘住,造成 Distribu-

tor 的损坏。

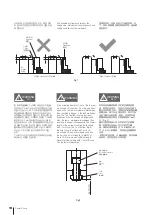

Position of Set Jaws

The T-Nut must not be protrude from the

master jaw(see Fig.7 right) Incorrect usage

will cause damage to the master jaw and

T-nut as well as inaccuracy. If T-nut is used

with it extruded(see Fig.7 left), it will cause

inaccuracy. Also the master jaw or T-nut will

be broken. The jaw or workpiece discharge

thus resulting in danger.

1. 卡爪座的 Serration(梳齿) 和 T-螺

母在更换 Top Jaw 时 应清洁。否则精

度会下降。

2. 根据工件形状和切削条件,设定空气

压力。管子形状的工件在高压握持时

会变形。

3. 不要使用 Serration(梳齿) 不合适

的卡爪座和Top卡爪。否则握持力精

度会降低,卡爪座受损。

4. 如果机器长时间不使用,不要将工件装

到卡盘上。

5. 如果因为不合适的操作或错误操作,导

致 Tool 或 Tool Holder 对卡盘造成

冲击,要马上停止机器,检查 Top 卡

爪,T-螺母的固定螺杆,紧固精度是

否正常。

6. 如果使用特殊高度的 Top 卡爪,空气

压力应小于使用标准 Top 卡爪时的

情况。

7. 卡盘的润滑十分重要。如果润滑不良,

握持力会不充分,发生非正常的磨损。

8. 使用卡盘时不要超过最大空气压力。

(参照25页)