23

Instruction Manual

5-2

5-2

5-2

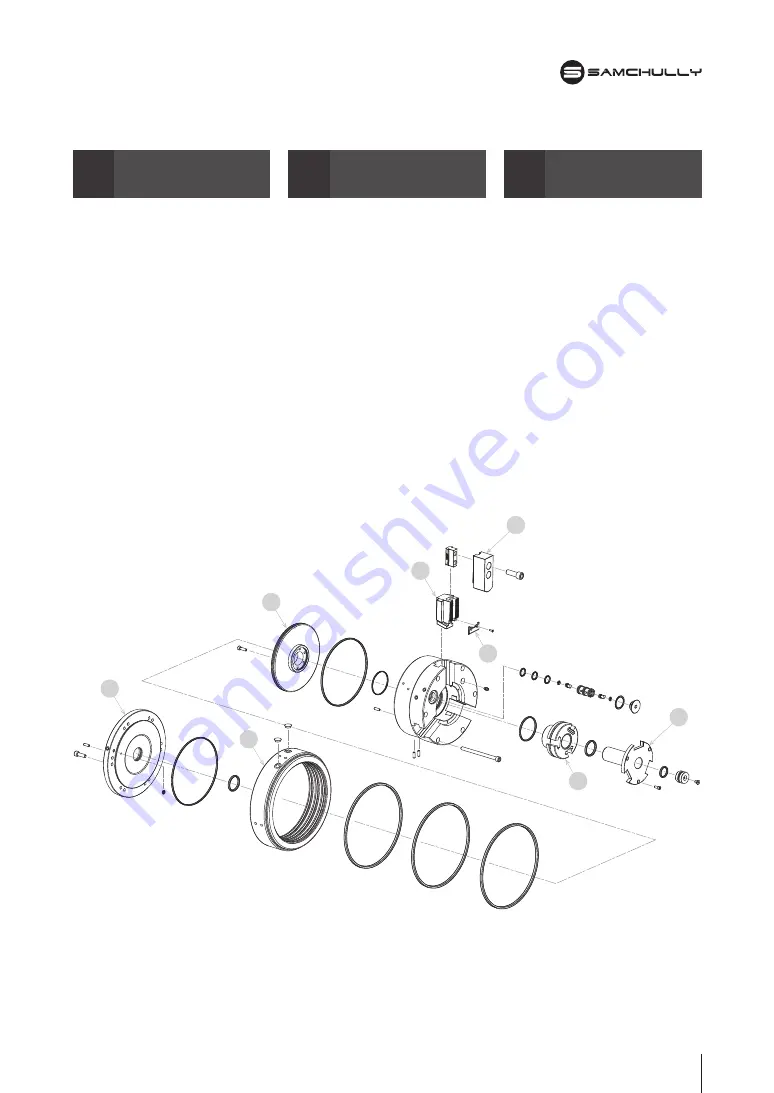

Disassembling

steps

分解顺序

분해순서

1. Loosen the screws of the top jaw, and

remove the top jaw and T-nuts.

2. Loosen the screws of the seal cover, and

remove the seal cover.

3. Loosen the screws of the back plate, and

remove the back plate.

4. Remove the distributor.

5. Remove the piston plate.

6. Loosen the screws of the cover, and

remove the cover.

7. Remove the wedge plunger.

8. Remove the master jaw.

Fig.10

1

6

2

7

3

4

5

8

1. 탑죠의 나사를 풀고 탑죠와 T-너트

를 분리합니다.

2. 씰 커버의 나사를 풀고 씰 커버를

분리합니다.

3. 백 플레이트의 나사를 풀어 백 플레이트를

분리합니다.

4. 디스트리뷰터를 분리합니다.

5. 피스톤 플레이트를 분리합니다.

6. 커버의 나사를 풀어 커버를 분리합니다.

7. 웨지 플런저를 분리합니다.

8. 마스터 죠를 분리합니다.

1. 松开 Top 螺丝,拆卸 Top 卡爪和 T-

螺母。

2. 松开 密封塞 螺丝,拆开 密封塞。

3. 松开 后盘 螺丝,拆卸 后盘。

4. 拆卸 Distributor。

5. 拆卸 活塞盘。

6. 松开 盖子 螺丝,拆开 盖子。

7. 拆卸 模柱塞。

8. 拆卸卡爪座。