19

Instruction Manual

1) 조정하기 전에 테이블의 공작물, 지그 등을 제거하고 테이블의 수평을 맞

추십시오. (그림 6)

2) 배출구에서 윤활유를 제거합니다.

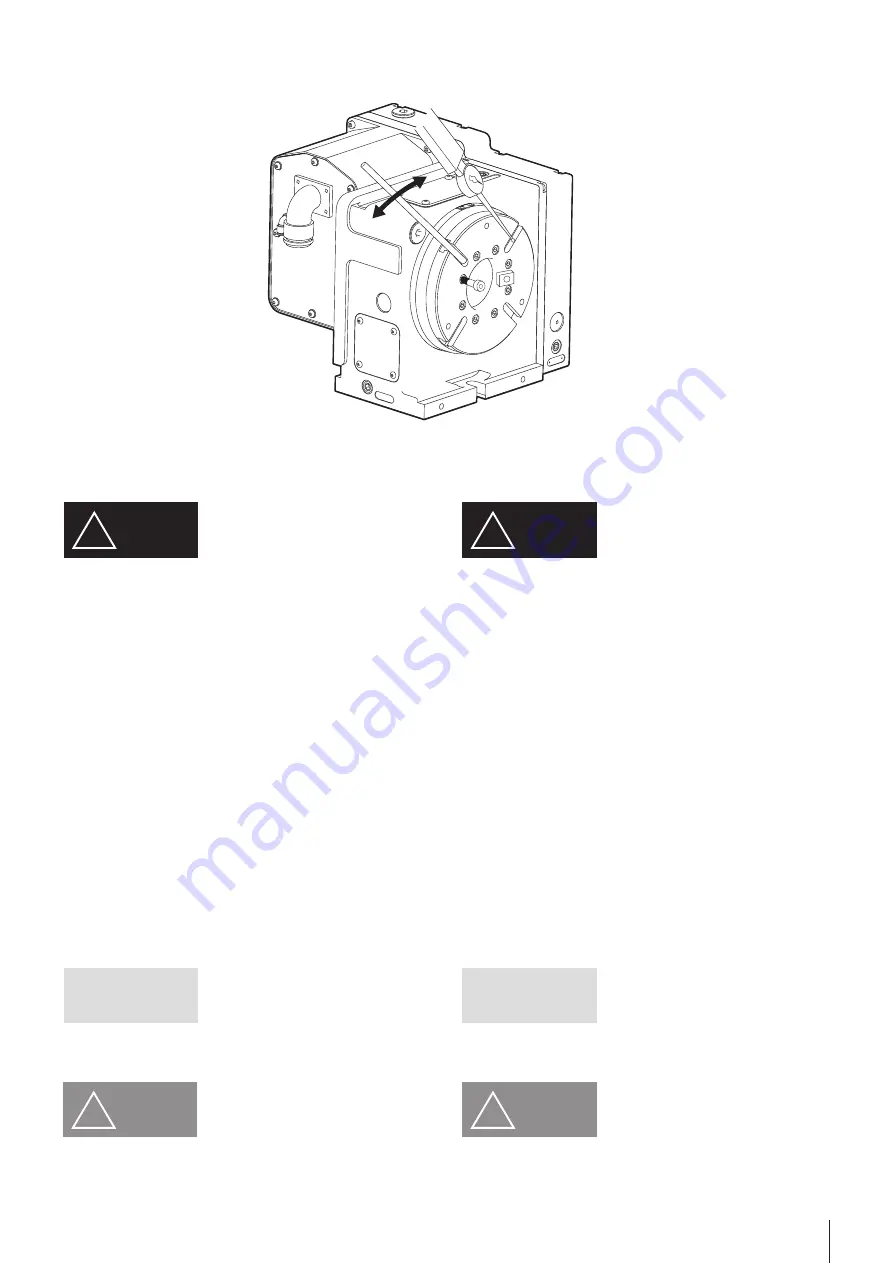

3) ①HOUSING COVER를 제거합니다.

4) ②HOUSING PLUG를 제거합니다.

5) ③HOUSING 정면에 체결된 ④SETSCREW 3개소를 느슨하게 풀고

③HOUSING 정면에 체결되지 않은 곳에 BOLT를 2개소 부분에 체결합니

다. (HOUSING 회전에 필요)

6) ③HOUSING에 체결한 BOLT를 손으로 잡고 회전하여 백래시량을 조정

한 후 ⑤WORM SHAFT 육각 홈 부분에 T-WRENCH를 삽입하여 백래시

량의 정도를 확인합니다. (참고: 백래시량 측정방법은 본 설명서 18 Page

WORMGEAR BACKLASH 조정법에 기재되어 있으니 확인하시기 바랍니

다. 백래시는 시계방향으로 회전할수록 작아집니다.)

7) 백래시 조정이 완료되면 ③HOUSING 전면에 체결된 ④SETSCREW 3개

소를 완전히 잠그고 BOLT 2개소 제거합니다.

8) 백래시 조정을 종료합니다.

1) Before adjusting backlash, remove the workpiece and jig from the

table, and set the table in horizontal position. (Fig 6)

2) Remove lubricant from the exit.

3) ①Remove the housing cover.

4) ①Remove the housing plug.

5) Loosen three ④screws on the front of the ③housing. Install bolts

into the two taps on the front of the ③housing where there is no bolt

(Required for turning the housing).

6) Adjust the backlash by turning the housing ③with the bolts using

hands. Insert a T-wrench into the hexagonal recess of the ⑤worm

shaft. (Note: refer to Worm Gear Backlash Adjustment, page 18 of

this manual. The backlash is reduced when the housing is turned

clockwise.)

7) When the backlash has been adjusted, tighten the three ④screws on

the front of the ③housing, and remove the two bolts.

8) Backlash adjustment is completed.

7.1.2 웜 기어 백래시 조정

7.1.2. Adjusting backlash of worm gear

IMPORTANT

유의사항

HOUSING을 시계방향(CW)으로 1회전하면 백래시는 작아집니다.

백래시 조정을 할 경우에는 반드시 제어장치의 전원을 OFF, 또한 NC 로터리

테이블을 언클램프 상태로 한 후에 조정해 주십시오. 회전중에 잘못하여 손

이나 의복이 기어에 닿으면 말려들어가 큰 사고로 연결될 염려가 있으니 주

의하십시오.

IMPORTANT

The backlash is reduced when the housing is rotated by on turn

clockwise.

When adjusting backlash, the power of the controller must be turned

off and the NC Rotary Table must be unclamped. Your body or clothes

can be caught in the machine during rotation, which leads to a serious

accident.

!

DANGER

위 험

!

DANGER

!

CAUTION

주 의

백래시를 성급하게 조정하지 마십시오. 천천히 조심스럽게 조정하십시오.

!

CAUTION

Do not adjust the backlash abruptly. Adjust it slowly and carefully.

[ 그림 / Fig.5 ]

Summary of Contents for SR-200

Page 2: ...2 NC Rotary Table...