Doc.-ID: 160319-PT08BA-TG-ExCam IPQ1775 series_en_rev.01.docx, Seite 25 von 40

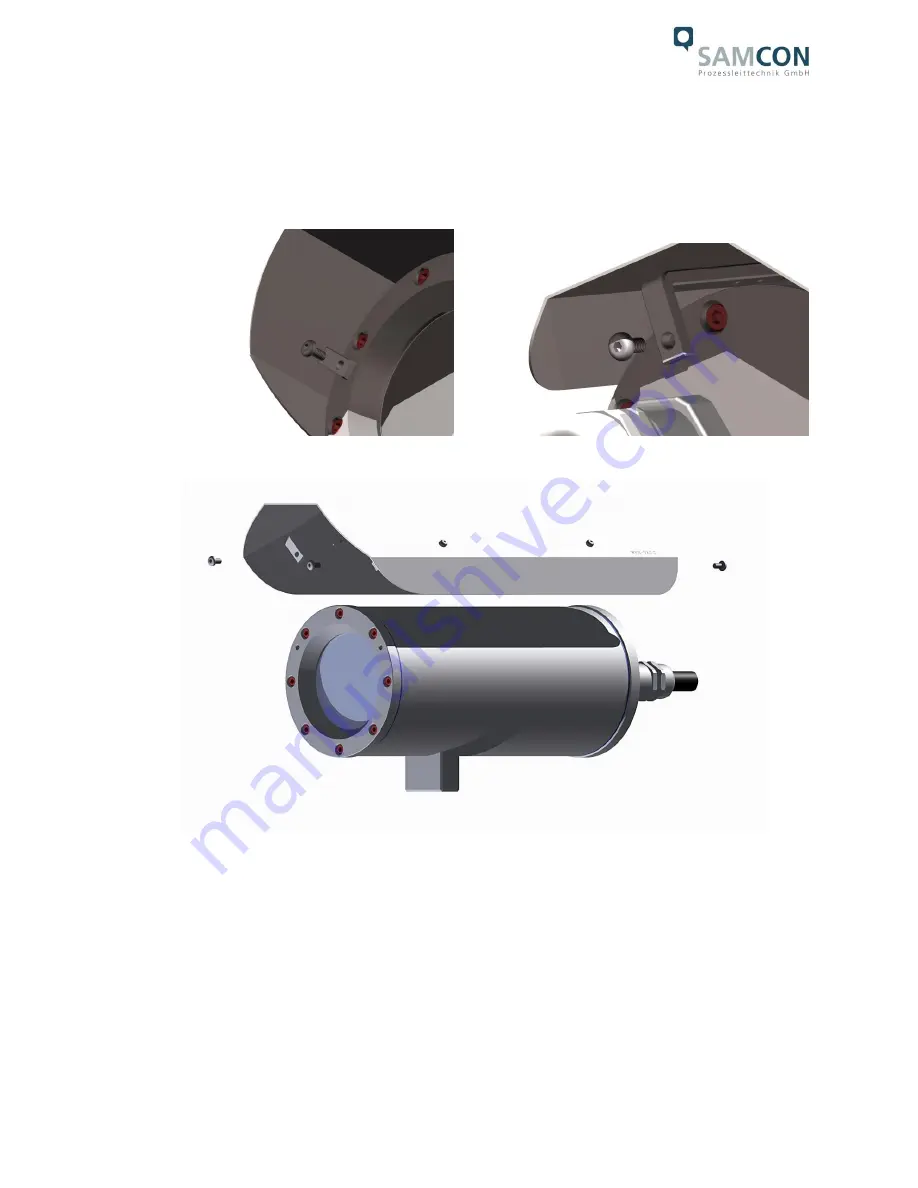

In case the T08 ExCam IPQ1775 is equipped with a protection roof, it has to be removed

first. To do so, loosen the four 8 mm lens head screws M4*0.7 at the front and back of

the bracket (figure 6.10 and figure 6.11).

Figure 6.10

– Removing the protection roof_1

Figure 6.11

– Removing the protection roof _2

To open the enclosure (T07 VA2.2) of the ExCam IPQ1775, loosen the four hexagon socket

screws (DIN 912/ ISO 4762) located at the cable gland flange of the stainless steel housing,

including the washer springs (DIN 127 A) (q.v. figure 6.10). Avoid skin or clothing contact

with the screw threads as they dispose o

f LOCTITE ® 243™ (chemical basis: Dimethacry-

latester). It is used to protect the screws from losing due to shocks, vibrations, but also for

sealing purposes.