SAMES KREMLIN

- 1 -

N° : 578.023.120-UK-1903

1.

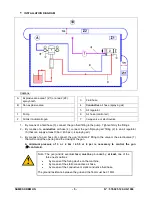

AIRMIX® ATOMIZATION PRINCIPLE

The spray air cap of the AIRMIX

gun is composed of 2 functional elements : a spray tip and an air cap.

Atomization takes place in two phases :

1. The fluid is pre-atomized by going through the spray tip under pressure.

2. Atomization is improved by means of very low pressure atomizing air jets.

The end results is a fine uniform atomization that guarantees an excellent finish without excessive

overspray. This results in very important air and fluid savings and cleaner working conditions - in

comparison with a conventional air spray gun.

2.

OPERATING

Safety instructions :

•

Never try to stop the spray fan with any part of the body (hands, fingers…) or with

rags. Never point the spray gun at anyone or at any part of the body.

•

The operator will need medical attention if the high pressure material spray is in

contact with the the body (eyes, fingers…).

•

Always lock the gun trigger with the safety device when not operating the gun.

•

Always depressurize air and hoses

before carrying out any servicing on the

gun.

In order to protect the operator, protective clothing (gloves, respirator

mask, glasses, hearing protective earplug, clothes…) are required.

Use the equipment in a properly ventilated area.

1 - Prime the pump.

2 - Unscrew the air adjuster on the base of the gun.

3 - Select a spray tip (refer to AIRMIX® spray tip chart).

4 - Make sure white seal (or micro-filter) is in place in the spray tip.

5 - Carefully press the spray tip into the air cap back being certain the locating pins are aligned with

mating recesses of the tip.

6 - Insert the air cap with its tip into the retaining ring. Screw retaining ring and air cap firmly onto the

spray gun positioning the air cap to obtain the desired pattern orientation.

7 - Adjust the air pressure for the desired flow rate.

8 - If tails or heavy deposits of sprayed material occur at the ends of the pattern, increase the

atomizing air pressure until the pattern is even.

9 - If using an adjustable air cap, pattern width can be optimized with the air adjusting knob.

Nota : if more material or less material are required, select another spray tip (refer to AIRMIX® spray tip

chart).