23

Maintenance kit FStart Pressure / Suction 129.756.902 composed of:

A

Needle packing

129.756.903

B

Trigger set + air adjusters

129.756.905

C

Rear line assembly

129.756.904

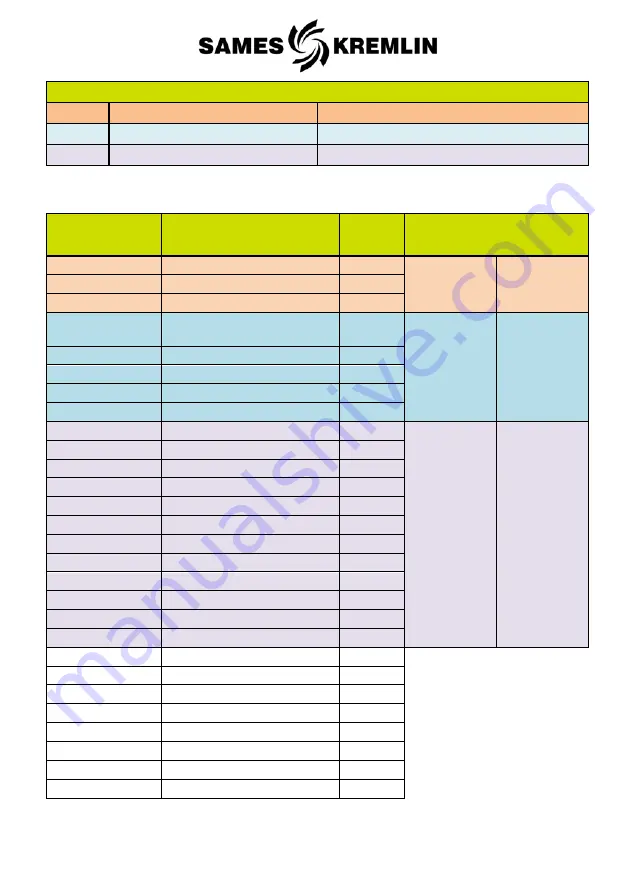

16.2

Parts list and FStart Pressure / Suction maintenance kit

(spare parts)

Positions

Designation

Quantity

Included in maintenance kit

129.756.902

4

Needle packing

1

129.756.903

Needle

packing

A

5

Packing gasket

2

6

Needle packing screw

1

7

Pattern adjustment valve

set

1

129.756.905

Trigger set

+ air

adjusters

B

21

E-ring

1

22

Trigger

1

23

Trigger stud

1

25

Air adjustment valve set

1

8

Gasket

1

129.756.904

Rear line

C

9

O-ring

1

10

Sleeve

1

11

Packing bushing

1

12

Air valve packing

1

13

Air valve set

1

14

Spring

1

15

Spring seat

1

16

O-ring

1

19

Spring

1

20

Fluid adjustment screw

1

27

O-ring seal

1

1

Aircap ring

1

2

Nozzle

1

3

Gun body

1

17

Fluid adjustment seat

1

18

Needle set

1

24

Fluid connector

1

26

Air connector

1

28

Cup

1