SAMES KREMLIN

- 1 -

N° : 578.007.120-UK-1707

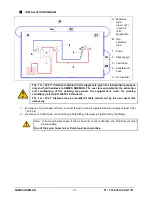

1.

START-UP

Safety instructions :

Never try to stop the spray fan with any part of the body (hands, fingers…) or

with rags. Never point the spray gun at anyone or at any part of the body.

The operator will need medical attention if the high pressure material spray is in

contact with the the body (eyes, fingers…).

Always depressurize air and hoses

before carrying out any servicing on the

gun.

In order to protect the operator, protective clothing (gloves, respirator

mask, glasses, hearing protective earplug, clothes…) are required.

Use the equipment in a properly ventilated area.

1- Unscrew the needle adjustment knob at the back of the gun.

2- Unscrew the air adjuster(s) (except for the Fpro Lock P spray gun).

3- Select the desired projector ( needle) best suited for the job at hand.

4- Screw on the nozzle, then the aircap to the gun.

We advice you to put the gun in the ‘OPEN’ position to prevent any damage to the needle while

fitting the nozzle

5 -Before tightening up firmly the aircap ring, position the aircap for the best spray. The fan is vertical

when the 2 ‘ears’ of the aircap are horizontal.

6 - Trigger the gun.

2.

ADJUSTMENT

This professional spray gun features 3 controls :

SPRAYING FINENESS

It is realized by the central air. The air is adjusted by means of the air regulator mounted upstream of

the gun on the network and more finely by means of the knob at the bottom of the gun handle of

some manual guns (optional for the Fpro Lock P spray gun).

FAN WIDTH (optional for the Fpro Lock P spray gun)

Can be adjusted by using the knurled knob. It controls the air going to the horns on the aircap. In this

way, the air is controlled through the fanned air outlets and allows the fan to change from flat (wide

open) to round (closed).

FLUID OUTPUT

Having selected the proper fluid nozzle / needle assembly and the fluid pressure, it is possible to

further control the output by changing the travel of the needle (needle stop knob) (optional for the

Fpro Lock P spray gun).

Optimal set-up is usually obtained when the product needle is completely open. When this needle is

nearly closed, a regular flow of product can not be guaranteed.