SAMES KREMLIN

- 1 -

N° : 578.026.110-UK-1708

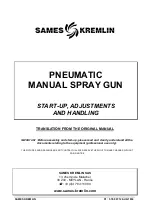

DISTORTED SPRAY

Slightly unscrew the aircap retaining ring and rotate the aircap by

one half turn. If the defect is reversed, one of the lateral air holes

is plugged up or deformed. Clean the gun aircap with solvent and

unclog the air holes with a compressed air. If the defect is not

reversed, it means that the fluid nozzle is damaged.

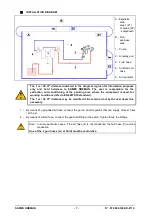

DISPLACED SPRAY

This comes from a defect in the central fan. Clean the aircap and

the fluid nozzle. Make sure that :

- the aircap is correctly centered on the nozzle,

- the nozzle is not too big for the needle,

- when work is done with a large needle opening and the needle

almost closed, the spray pattern is not even in all directions.

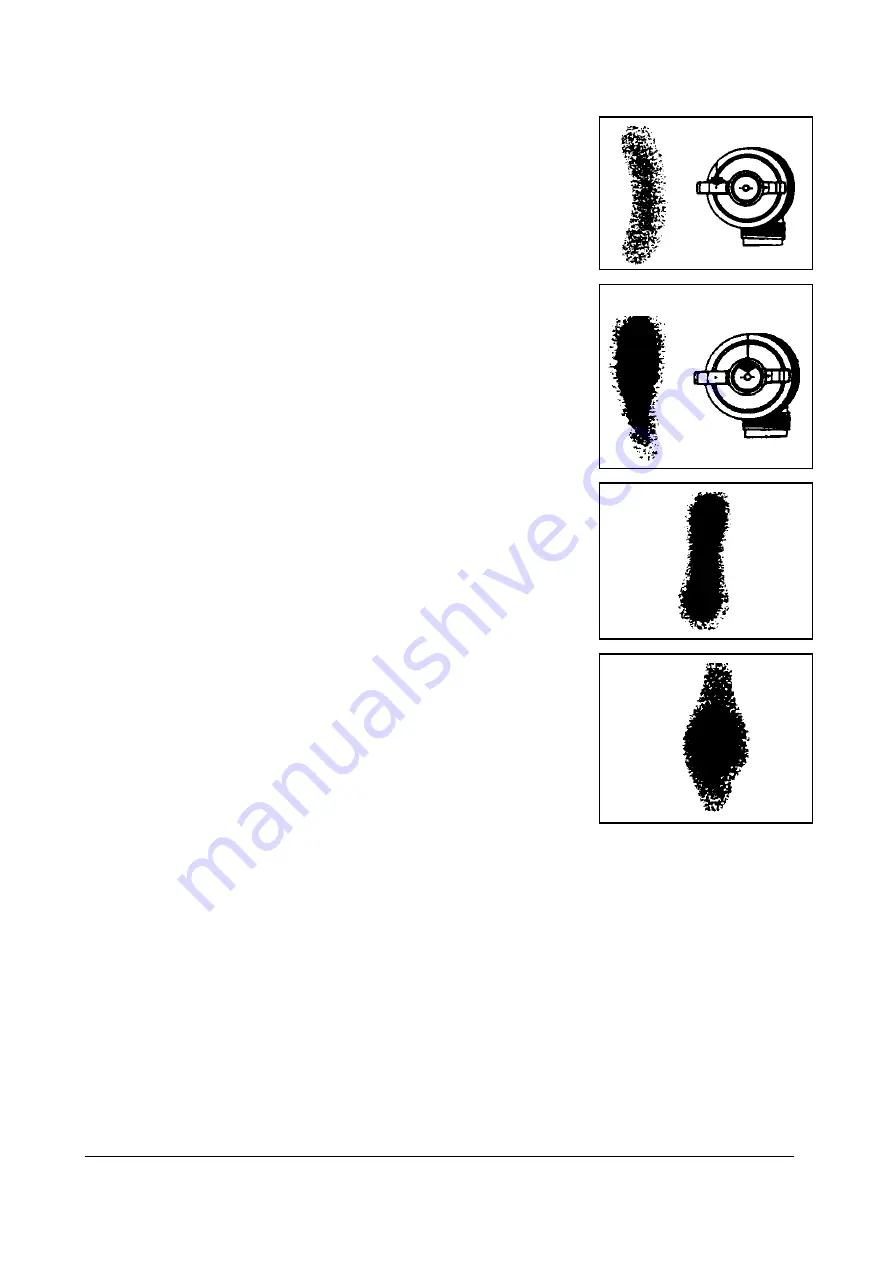

FRAGMENTED PATTERN

The fan air pressure is too high at the holes in the air cap horns :

- turn the fan air control clockwise to reduce the fan air pressure,

- increase the paint output.

FAN TOO THICK IN THE CENTER

This is the reverse of the above defect :

- the paint output is too high for the selected air pressure :

increase the spraying air pressure and reduce the paint output.

- if the paint is too thick, dilute it.

INTERMITTANT SPRAY PATTERN

An air inlet in the paint circuit creates an intermittant pattern when :

- the paint cup is nearly empty,

- when the nozzle is not tightened on its seat : clamp it.

If the problem persists, remove the nozzle and clean it. Check that the seat and the cone are not

damaged, remove the nozzle and clamp it.

Check that : the cup cover air hole is not blocked and the paint is homogeneous and fluid enough

(use the viscosity cup).

Check that the ‘pressure’ gun is not used with a ‘suction’ cup.