Index revision : A

21

7129

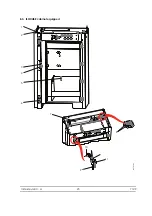

5.1.1.3. Receptacle

• The receptacle may be cleaned when it is outside the cabinet using a pressurised water

spray (max. 130 bar, temperature 40°C).

If using a rotating nozzle, make sure you do not damage the surface of the equipment,

which would make it increasingly difficult to clean over time.

• Dry very carefully with compressed air on all the surfaces, particularly the edges and

cavities.

5.1.2. Electro-pneumatic strip

• Clean with a cloth soaked in water. If there is heavy dirt, the front and the windows of the

air pressure indicators may be cleaned with a cloth soaked in water or non-aggressive,

non-greasy and non-flammable solvent. Do not use butyl-glycol.

In this case, make sure that the solvent does not come into contact with the electric but-

tons and lights, or with the pressure regulator buttons or with the front panel's metal sheet

.

• Dry by wiping with a dry cloth. While compressed air is not prohibited, it must only be used

at moderate pressure (max. 2 bars - 30 psi) on this part of the cabinet.

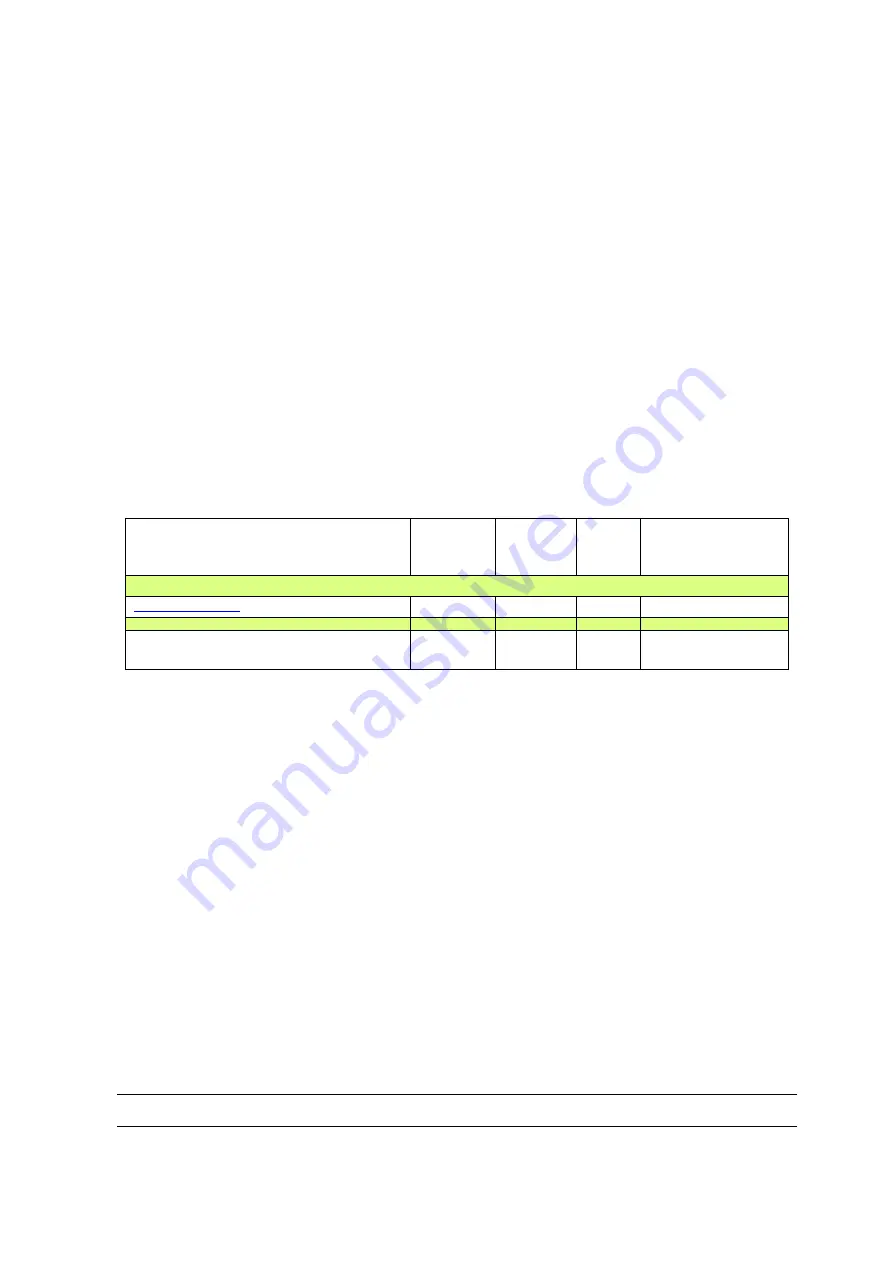

6. Maintenance

* Fuse characteristics:

10*38 500V 4A class gG.

Detail

Preven-

tive

measure

Correc-

tion

Dura-

tion

Frequency

Short circuiter 100 kV

Replacement of the electro-pneu-

matic box fuse*

X

5 mn

-