Version B June, 2020

49

MagnaRam-SK

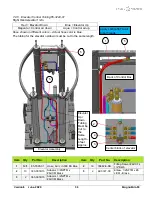

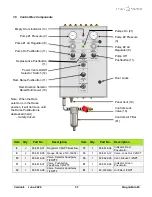

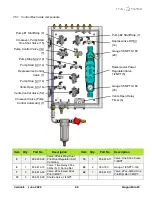

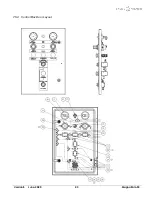

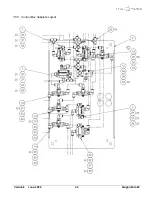

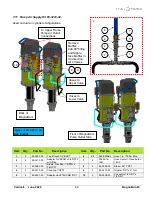

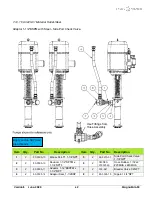

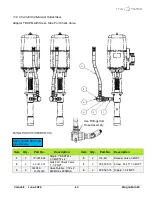

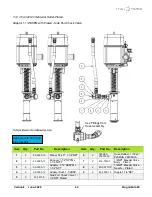

7.9 Upper Frame Pneumatic Assembly 65-3225-01

The Pneumatic Assembly is bolted to the Upper Frame.

Pilot regulators are 1:1 ratio Maximum Psi 87 Psi (6 bar)

Item Qty.

Part No.

Description

Item Qty.

Part No.

Description

1

1

82-1100-20

Elbow, 3/8NPTx3/8Tube

15

1

82-3667-00

Reducer, 1”NPT x 1/4”NPT

2

1

85-5595-03

Reducer,

1NPTx3/8Npt St.

16

1

KQ2U07-35S

Y Fitting ¼”NPT x ¼”Tube

3

4

361-127AQ

Tee, HP 1NPT

17

8ft.

668-030-136

Tubing, Polyethene ¼”O.D.

4

3

82-3661-00

Adapter, Hex 1Jic x 1NPT(M)

18

2

85-5595-05

Elbow, 1”NPTF Galv.

5

2

82-3683-00

Muffler 1NPTM

19

2

82-1100-14

Elbow, 1/4NPT x ¼ Tube

6

2

82-5358-07

Channel 1-5/8 x 1-5/8 x 1ft.

20

2

350-328AQ

Elbow, St. 90º 1”NPT

7

5

82-3663-00

Nipple, Hex 1NPT

21

1

85-5633-02

Nipple 1”NPT x 3.5” Galv.

8

2

365-130

Pilot Regulator,Air Valve 1NPT

22

1

85-5633-01

Bushing 1”NPT x ½”NPTF

9

1

72-3098-02

U-Bolt, Sq. 3in. 3/8-16 Thd.

23

1

65-3313-00

Coil Hose, ½ I.D. ½”NPTM

10

2

82-5357-03

Clamp, Tube 1-5/16” Strut

24

2

85-5682-02

Nipple, Close 1”NPT Galv.

11

1

85-5595-04

Nipple, Pipe 1”NPT x 14” Galv.

25

1

85-5633-04

Ball Valve,1”NPT-Lock/Exh

12

1

82-3668-01

Nipple, Pipe 1”NPT x 36” Galv.

26

1

365-132

Muffler, Sintered ¼”NPT

13

1

72-3098-01

U-Bolt, Sq. 6in. 3/8-16 Thd.

27

2

85-5633-03

Ball Valve,1”NPT-Lock

14

1

82-2004-06

Plug, 3/8” Push Lock

28

1

906-333-102

Pipe Plug, 1/4NPTM Plated

18

22

26

24

18

4

23

24

21

25

7

x5

10

6

13

12

3

x4

2

16

15

3

x4

1

10

6

9

11

4

3

x4

5

8

20

7

x5

5

19

27

27

20

4

8

7

x5

14

28

Apply Loctite 567 to all

pipe threads.

Summary of Contents for Magna-Ram

Page 1: ...USER MANUAL Magna Ram 300 Gallon Elevator and Controls...

Page 17: ...Version B June 2020 17 MagnaRam SK 3 2 Ram Retracted 3 3 Ram Extended...

Page 18: ...Version B June 2020 18 MagnaRam SK 3 4 Load Height...

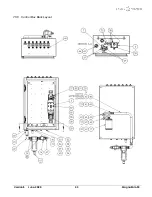

Page 43: ...Version B June 2020 43 MagnaRam SK 7 6 4 Control Box Door Layout...

Page 44: ...Version B June 2020 44 MagnaRam SK 7 6 5 Control Box Subplate Layout...

Page 45: ...Version B June 2020 45 MagnaRam SK 7 6 6 Control Box Back Layout...

Page 80: ...Version B June 2020 80 MagnaRam SK 10 Control Drawings 45 0538 00 Drawings...