Index revision : A

16

7116

2.2. Function of the parts

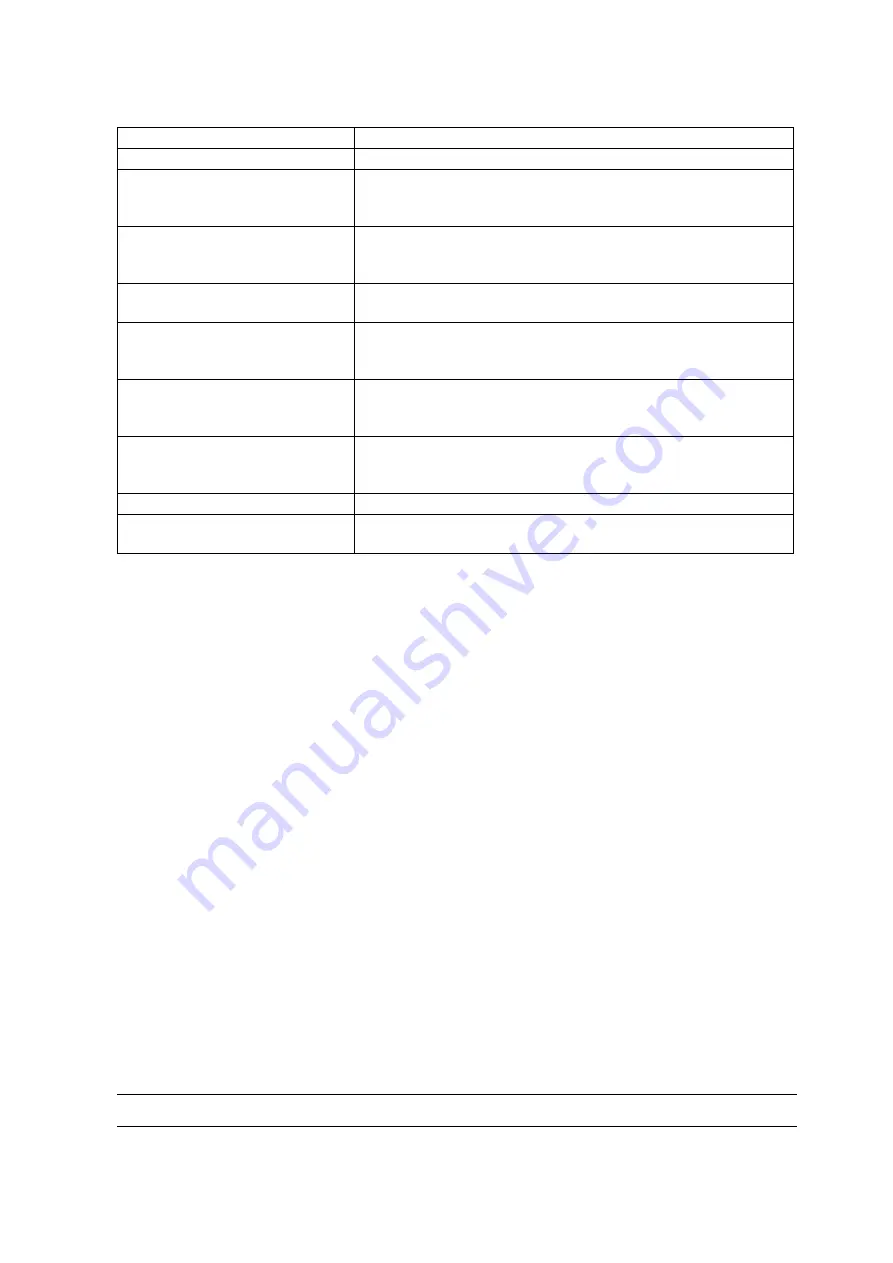

Part

Function

Bell cup

The bell cup atomizes all types of liquid products.

Shaping air assembly

(Outer cover / Shaping air

shroud)

These parts control the size and pattern diameter and transfer

the particles to the parts to be coated. They protect internal

components and allow easy cleaning.

Turbine

The rotation of the bell cup is produced by a pneumatic motor.

Atomization results from the centrifugal forces generated by

rotation of the bell cup.

Injector / Injector holder

The injector transfers products to the bell cup. The holder

retains the injector and allows it to be rinsed.

Body assembly

This part houses all fluid circuits and air/solvent microvalves

and nanovalves. It supports the turbine and the shaping air

assembly.

Nanovalve and microvalve

Air-controlled, 2-way, normally closed valves used for various

operations: product supply, product rinsing, bell cup exterior

rinsing, injector rinsing.

Quick-disconnect plate

Provides a sealed interface for intake of fluids and air prevent-

ing any contamination. Allows quick installation and removal of

the atomizer during production.

Nut

It secures the body on the support tube.

High voltage connection

Supply with high voltage the PPH 707 CHEM ICWB M TI

atomizer from the external high voltage unit.