53

Member of Exel group

DRT582221110

B - 2023/01

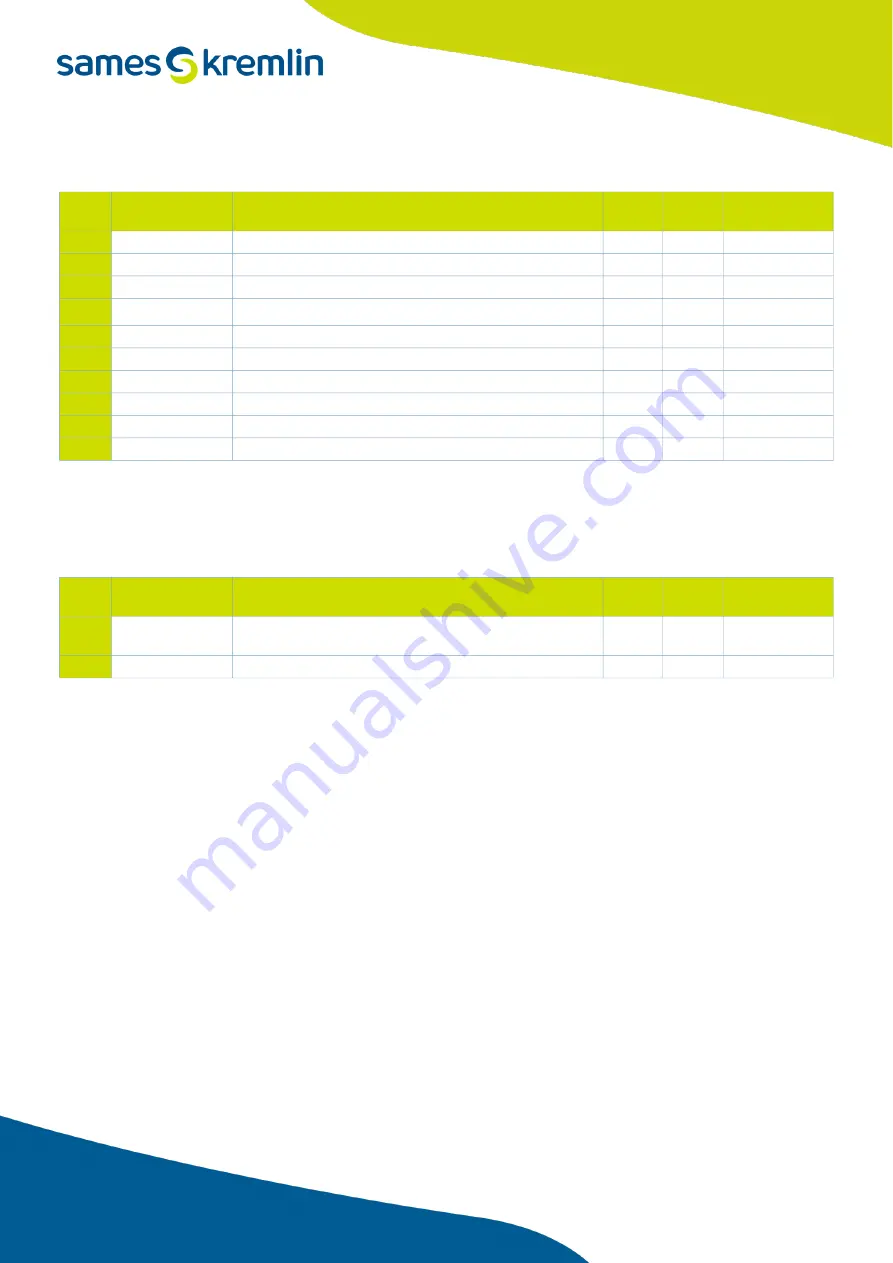

Specific parts for

Xcite

®

+ Gun

(*)

Level 1: 1st emergency parts

Level 2: Wear parts

Specific parts for

Xcite

®

+ Light Gun

(*)

Level 1: 1st emergency parts

Level 2: Wear parts

Item

Part number

Description

Qty

Sales

unit

Spare parts

level (*)

20

129 520 370

Cup and nut assembly

1

1

-

20.1

029 520 306

• Nut

1

1

-

20.2

029 520 372

• Filter body

1

1

-

21

129 720 085

Assembled product tube without tank Xcite

®

1

1

-

21.1

029 720 083

• Screen support

1

1

-

21.2

129 609 908

• Screen n°6 (package of 5)

1

1

1

21.3

129 529 918

• Seal PTFE (package of 10)

1

1

1

21.4

934 081 332

• Screw stainless steel

1

1

-

21.5

-

• Protective tube

1

0

-

21.6

029 670 072

• Spacer

1

1

-

Item

Part number

Description

Qty

Sales

unit

Spare parts

level (*)

16

905 210 709

Stainless steel fitting, double male 1/2 JIC

500 bar / 7252 psi

1

1

-

17

129 209 902

Seal, tip (package of 5)

1

1

1