Index revision : C - March 2016

62

7105

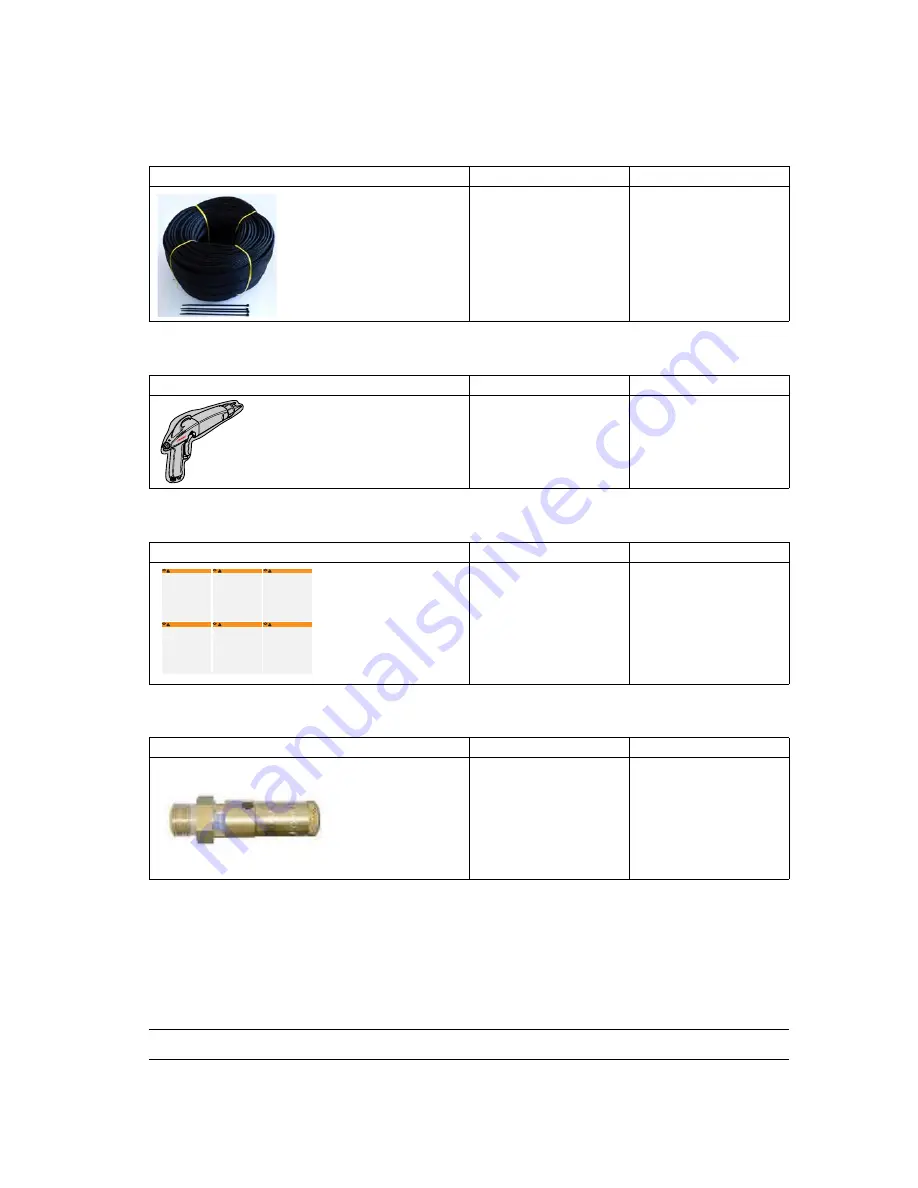

13.14. Appendices

13.14.1. Protective hose covering

This covering can be used to protect hoses and cables to ensure long life and flexibility.

13.14.2. Protective case for spray gun

13.14.3. Warning notice

13.14.4. Safety valve

Description

Part number

Unit of sale

Rilsan Protective hose

covering with 30 collars

910021086

50 m roll

Description

Part number

Unit of sale

Protective case

900011711

10

Description

Part number

Unit of sale

Warning

notice

1407684

1

Description

Part number

Unit of sale

Safety valve 6.5 bar

1/4 G

903080401

1

DES01269

N˚ Sames 1407684

This sign must be hung in the booth.

Manual electrostatic equipment for the application of paint or varnish

• This equipment must only be used by SAMES trained personnel.

• The command module must be located at least 1,5m from the booth openings.

• The use of the command module must be completely dependent upon the running

of the booth's exhaust fan.

• Regroup the cables and pipes arriving to the spray gun to prevent them from

dragging on the ground where they could be severed.

• Only metallic recipients must be used for cleaning liquids. They must definitely be

grounded.

• Use cleaning liquids with a flash point higher than ambient temperature.

• Correctly ground all of the metallic parts in the booth, as well as the parts to be

painted.

• The operator and persons working nearby must wear antistatic shoes.

• The operator's hand must be in contact with the spray gun grip.

• Work on an antistatic floor such as bare concrete or a metallic grating.

• Switch off the command module for any maintenance operation, in particular for the

cleaning of the nozzle and the cap, and for the rinsing of the paint circuit with the

cleaning liquid.

• If the spray gun is equipped with a trigger lock, it must be engaged during the

cleaning of the nozzle and the cap and during a prolonged stop.

• The electrostatic application equipment must be maintained on a regular basis and

repaired according to the instructions in the manual.

WARNING

GB

WARNUNG

Elektrostatisches Handgerät zum Auftragen von Farben/Lacken von

• Dieses Gerät darf nur durch von SAMES ausgebildetem Personal bedient werden.

• Das Steuermodul ist mindestens 1,5 m von den Öffnungen der Kabine entfernt

anzubringen.

• Die Inbetriebnahme des Steuermoduls muss vom Betrieb des Ventilators des

Abzugs der Kabine abhängig sein.

• Zur Lackierpistole führende Kabel und Schläuche gruppieren, um zu vermeiden,

dass diese auf dem Boden liegen, wo sie beschädigt werden können.

• Für Reinigungsflüssigkeiten sind ausschliesslich Metallbehälter zu verwenden. Diese

müssen zuverlässig geerdet werden.

• Reinigungsflüssigkeiten mit einem Flammpunkt über der Raumtemperatur

verwenden.

• Alle Metallteile der Kabine sowie die zu beschichtenden Werkstücke sachgemäss

erden.

• Das Bedienungspersonal und Personal, das in unmittelbarer Nähe arbeitet haben

antistatisches Schuhwerk zu tragen.

• Die Hand des Bedieners muss direkten Kontakt zum Griff der Pistole haben.

• Auf antistatischem Fussboden, wie roher Beton, oder Metallrostfussboden arbeiten.

• Vor Wartungsarbeiten ist das Steuermodul auszuschalten, insbesondere für die

Reinigung der Düse, des Aufsatzes und zum Spülen des Lackkreislaufs mit

Reinigungsmittel.

• Wenn die Lackierpistole mit einer Sicherheitssperrvorrichtung für den Abzug

versehen ist, ist diese bei Reinigung de Düse, des Aufsatzes und einer längeren

Unterbrechung zu verriegeln.

• Die elektrostatische Beschichtungsanlage ist regelmässig zu warten und unter

Einhaltung der Anweisungen im Benutzerhandbuch zu reparieren.

Dieses Schild muss in der Kabine angebracht werden.

DE

WAARSCHUWING

Elektrostatische handapparatuur voor applicatie van verf/vernis

• Dit apparaat mag alleen door SAMES opgeleid personeel worden gebruikt.

• De bedieningsmodule moet zich op minder dan 1,5m afstand van de

cabineopeningen bevinden.

• De inwerkingstelling van de bedieningsmodule moet onderworpen zijn aan de

inschakeling van de zuigventilator van de cabine.

• Groepeer de kabels en leidingen die bij het pistool uitkomen zodat ze niet over de

grond slepen, waar ze kunnen worden afgesneden.

• Gebruik alleen metalen bakken voor de reinigingsvloeistoffen. Zij dienen op veilige

wijze op de grond te worden gezet.

• Gebruik reinigingsvloeistoffen met een vlampunt dat hoger is dan de

omgevingstemperatuur.

• Zorg voor een degelijke aardaansluiting van alle metalen cabine- onderdelen en alle

verfbare delen.

• De gebruiker en het personeel in zijn nabijheid dienen antistatisch schoeisel te

dragen.

• De hand van de gebruiker heeft direct contact met de kolf van het pistool.

• Werk op een antistatische grond zoals beton of een metalen rooster.

• Schakel de bedieningsmodule uit voor alle onderhoudshandelingen, vooral bij

reiniging van de loop of de beschermkap en bij spoeling van het verfcircuit met de

reinigingsvloeistof.

• Als het pistool is uitgerust met een trekkervergrendeling, dan dient u deze te

gebruiken tijdens reiniging van de loop of de beschermkap en tijdens langdurige

uitschakeling.

• De elektrostatische applicatieapparatuur dient regelmatig te worden onderhouden

en gerepareerd volgens de aanwijzingen in de gebruikshandleiding.

Bevestig deze plaat in de cabine.

NL

ADVARSEL

Manuelt udstyr til elektrostatisk påføring af maling/lak

• Udstyret må kun anvendes af personale, der er uddannet af SAMES.

• Betjeningsmodulet skal være anbragt mindst 1,5m fra kabinens åbninger.

• Betjeningsmodulet må kun kunne tændes, når kabinens udsugningsventilator er i

gang.

• Alle kabler og slanger, der er forbundet til pistolen, bør samles for at undgå, at de

flyder på gulvet, hvor de risikerer at blive skåret over.

• Rengøringsvæskerne må kun opbevares i metalbeholdere. Disse skal være sikkert

forbundet med jord.

• Der skal bruges rengøringsvæsker med et flammepunkt over stuetemperatur.

• Alle metalliske dele i kabinen såvel som emnet, der skal males, skal jordes korrekt.

• Operatøren og de personer, der arbejder i nærheden, skal bære antistatisk fodtøj.

• Operatørens hånd skal være i direkte berøring med pistolskæftet.

• Der skal arbejdes på et antistatisk underlag, såsom rå beton eller metalriste.

• Betjeningsmodulet skal sættes ud af drift inden al vedligeholdelse, specielt ved

rengøring af dysen eller hætten og rensning af malingskredsløbet vha.

rengøringsvæsken.

• Hvis pistolen er udstyret med en anordning til aflåsning af aftrækkeren, skal denne

være slået til under rengøringen af dysen eller hætten og ved længerevarende

standsninger.

• Udstyret til elektrostatisk påføring skal vedligeholdes regelmæssigt og repareres

ifølge forskrifterne i brugsvejledningen.

Dette skilt skal være anbragt i kabinen.

DK

VARNING

Manuell elektrostatisk utrustning för applikation av färg/lack

• Denna utrustning får endast användas av personal utbildad av SAMES.

• Manövermodulen skall vara belägen minst 1,5 m från hyttöppningana.

• Igångsättningen av modulen skall förutsätta inkoppling av hyttens utsugningsfläkt.

• Samla ihop kablar och slangar som går in på pistolen så att de inte ligger i vägen

på golvet, där de riskerar att skäras av.

• Endast metallbehållare får endast för rengöringsvätskor. De skall jordas på säkert

sätt.

• Använd rengöringsvätskor med en flampunkt som ligger över

omgivningstemperaturen.

• Jorda på korrekt sätt alla metalliska delar av hytten, liksom de delar som skall

målas.

• Operatören och personer som arbetar i närheten av de metalliska delarna skall

bära antistatiska skodon.

• Operatörens hand skall vara i direkt kontakt med pistolkolven.

• Arbeta på ett antistatiskt golv av typ bar betong eller en metallisk gallerdurk.

• Koppla bort manövermodulen vid varje underhållsarbete, i synnerhet vid rengöring

av munstycket, hatten och sköljningen av målningskretsen med rengöringsvätska.

• Om pistolen är utrustad med en avtryckarlåsning, skall denna vara ilagd vid

rengöringen av munstycket, hatten och vid ett långvarigt stopp.

• Den elektrostatiska applikationsutrustningen skall underhållas regelbundet och

repareras i enlighet med anvisningarna i användarmanualen.

Denna skylt skall placeras i hytten.

SE

VAROITUS

I n Käsikäyttöiset sähköstaattiset maalaus-/lakkausruiskut

• Laitteita saa käyttää vain SAMESin kouluttama henkilöstö.

• Ohjausmoduuli on sijoitettava vähintään 1,5 m päähän maalauskopin aukoista.

• Ohjausmoduulin toiminta on kytkettävä maalauskopin imutuulettimen

käynnistymiseen.

• Katkeamisvaaran välttämiseksi maalausruiskun johdot ja letkut on sijoitettava siten,

että ne eivät laahaa maata.

• Puhdistusaineille käytettävä ainoastaan metallisäiliöitä. Säiliöiden maadoitus on

varmistettava.

• Käytettävä puhdistusaineita, joiden leimahduspiste on korkeampi kuin ympäristön

lämpötila.

• Kaikkien maalauskopin metalliosien sekä maalattavan kappaleen asianmukaisesta

maadoituksesta on huolehdittava.

• Laitteiston käyttäjän ja sen läheisyydessä työskentelevien on pidettävä antistaattisia

jalkineita.

• Käyttäjän käden on oltava suorassa kosketuksessa maalauspistoolin peräosan

kanssa.

• Työskentelytasona on oltava antistaattinen pinta, kuten paljas betoni tai metalliritilä.

• Ohjausmoduulista on katkaistava virta kaikkien huoltotoimien ajaksi, etenkin

puhdistettaessa suutinta tai suojakupua ja huuhdottaessa maalikiertoa

puhdistusnesteellä.

• Jos pistoolissa on liipaisimen lukitustoiminto, sitä on käytettävä puhdistettaessa

suutinta tai suojakupua ja laitteiston ollessa pitempään käyttämättä.

• Sähköstaattinen maalauslaitteisto on huollettava säännöllisesti ja korjaukset on

tehtävä käyttöohjeiden mukaisesti.

Tämä kilpi on sijoitettava maalauskoppiin.

FI

DES00790