32

Member of Exel group

DRT7133

D - 2023/01

6. Maintenance

Preventive maintenance is an essential part of production and ensures the reliability of the installation. As a reminder,

the performance of equipment can only be guaranteed if a minimum of control and cleaning operations are performed

on this equipment.

Soiling and wear of the Inogun A projectors caused by the passage of powder

depend on the

operating and application conditions and the production rates

Switch off the power supply to the control module before connecting the spray gun. Before

disconnecting the spray gun, switch off, disconnect the power supply to the Inocontroller or

Inobox (otherwise, a malfunction may occur).

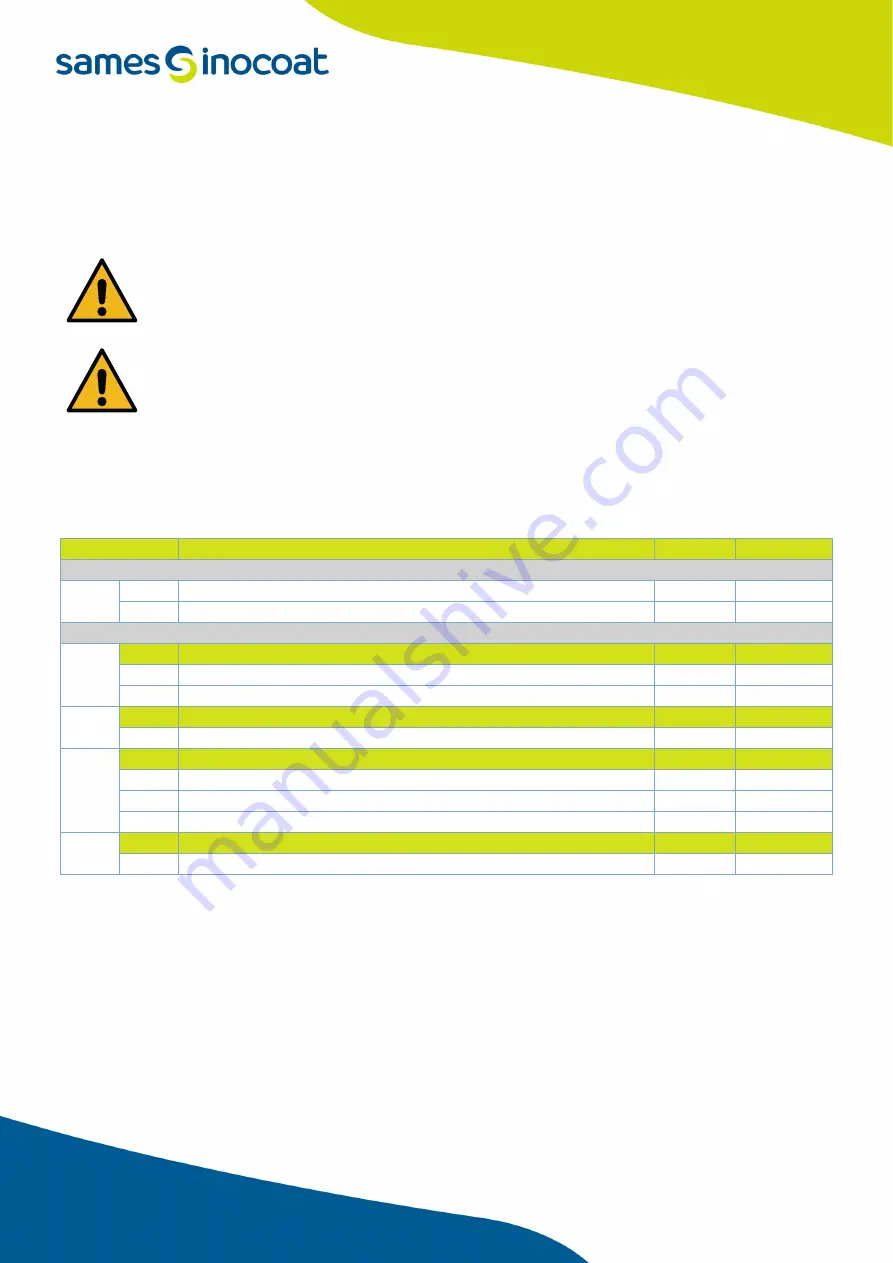

6.1. Summary table of maintenance operations

The maintenance intervals indicated in the procedures below are only indicative. The user will have to create his own

maintenance schedule as he use

Sames

equipment.

Procedure

Detail

Duration

Frequency

Cleaning

A

A1

Cleaning of projector exterior

2 min

8 hours

A2

Cleaning of electrode support and deflector

2 min

8 hours

Replacement

B

Holding flange maintenance

B1

Replacement of air nipple

2 min

-

B2

Replacement of o-ring

2 min

-

C

Rear body maintenance

C1

Replacement

5 min

-

D

Gun assembly maintenance

D1

Powder tube and penetrant testing version powder tube

2 min

-

D2

Protective cover assembly

2 min

-

D3

Replacement of HVU

5 min

-

E

Maintenance of 60° and 90° nozzle adapters

E1

Replacement of o-rings and 60° and 90° elbows

5 min

-

Summary of Contents for inocoat Inogun A

Page 1: ...Instruction manual DRT7133 D 2023 01 Inogun A FCC Standard and Robotic Versions...

Page 78: ...78 Member of Exel group DRT7133 D 2023 01 10 Appendices 10 1 Preventive maintenance plan...

Page 82: ...79 DRT7133 D 2023 01 Member of Exel group 10 2 EU and UK declarations of conformity...

Page 87: ...Sames 13 Chemin de Malacher 38240 Meylan France 33 0 4 76 41 60 60...