5

R. 09/20 855 867

SAMOA Industrial, S.A. · Pol. Ind. Porceyo, I-14 · Camino del Fontán, 831 · 33392 - Gijón - Spain · Tel.: +34 985 381 488 · www.samoaindustrial.com

2020_09_24-12:30

EN

This pump is self-priming.

To prime it the first time, you must connect the air pump supply to a low pressure using the pressure regulators while keeping the outlet valve open.

When fluid begins to flow from the pump outlet, the pump is primed. For regulation of fluid pressure, the unit must be supplied with an air pressure between

22 and 115 psi (1,5 and 8 bar), Hytrel

®

and Santoprene

®

betwween 36 and 115 psi (2,5 and 8 bar). Adjust the discharge valve on the discharge side to

control flow. For the performance characteristics of the pump see the capacity curve shown on page 6.

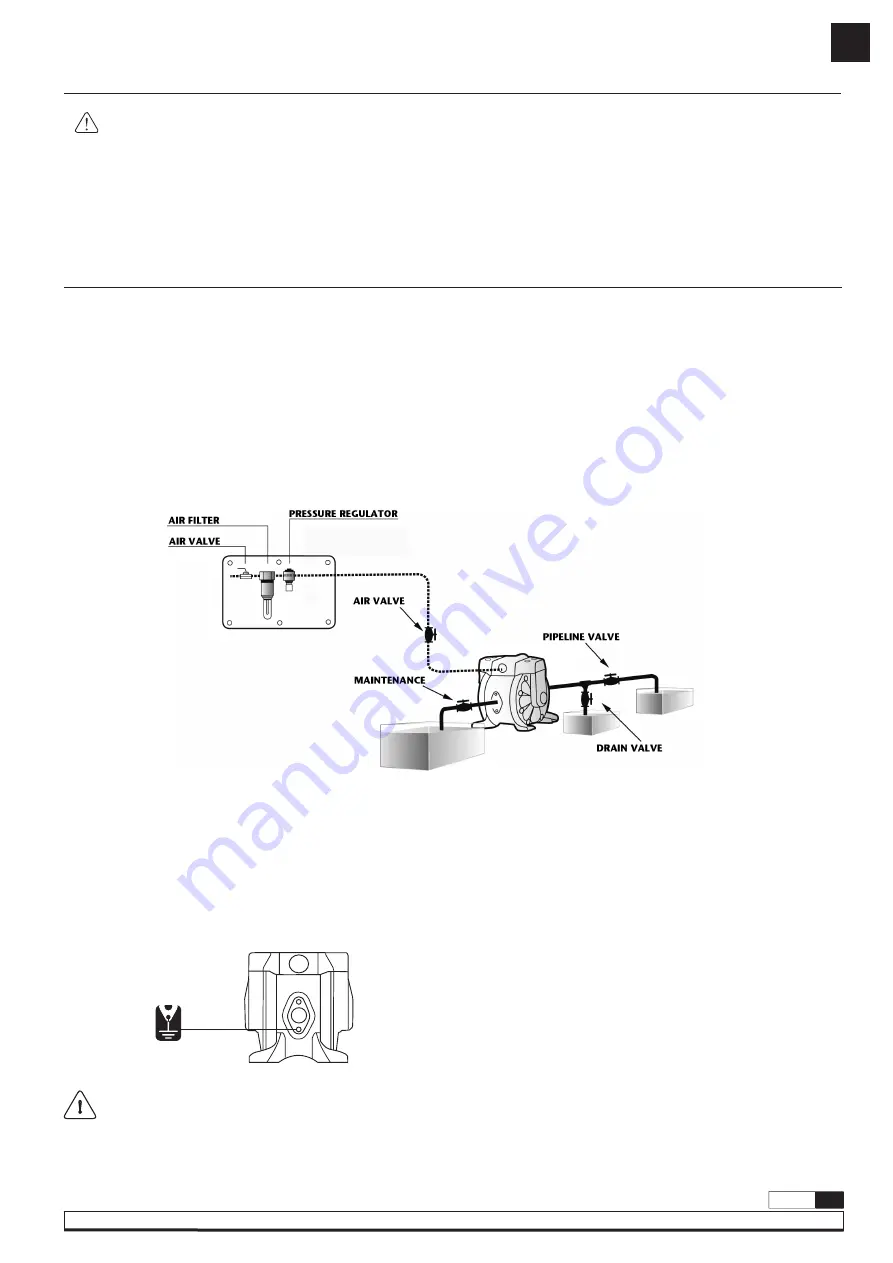

To ensure that the air supply is sufficient to meet the demand of the pump,

the diameter of the pipe must be equal to the diameter of the supply port of

the pump. Choose auxiliary air treatment equipment and fittings with

sufficient airflow to exceed the air consumption of the pump. In addition,

peripheral air treatment equipment must be installed as close as possible to

the pump unit.

The use of a coupler to connect the hoses aids future operation and

maintenance tasks.

• Close the inlet valve of the pump.

• Open the air valve of the pump, turn on the pump and flush the remaining fluid.

• Close the discharge valve on the discharge side, then begin to slowly open the drain valve and discharge pressure fluid.

• After ensuring that the pump was turned off and the pressure was released, fully open and close the regulator valve and drain valve of the pump.

• When installing the pump, be sure to perform grounding in the specified

location.

• Also connect ground wires for the auxiliary equipment and piping.

• Use a grounding cable of at least 12 gauge (2.0 mm

2

).

STICKER THAT SHOWS

THE POSITION OF THE

GROUND WIRE

WARNING: Connect grounding wires to the pump, piping and all other equipment too.

When the pump operates ungrounded or with an incorrect connection, friction between parts and abrasion caused by some fluids that flow

inside the pump, can generate static electricity. Moreover, according to the type of fluid pump and the installation environment (such as gases

in the air or the type of the surrounding facilities) static electricity can cause fire or electric shock.

INSTALLATION

WARNING

AIR CONNECTION

OPERATING INSTRUCTIONS

STOPPING THE PUMP

GROUNDING THE PUMP