www.larius.com

14

L400

REV.

02 - 02/2020 - Cod. 150085

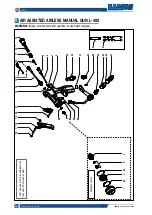

• Connect the flexible hose of product delivery

(P4)

to the gun

(P8)

.

Tighten the nut

(P9)

with a suitable wrench

(P7)

.

Fluid flow rate is controlled at the pump. Adjust the pump pressure

to obtain the desired flow rate; use lowest pressure necessary.

The pressure adjustment will depend on hose length, the viscosity

of the fluid, and the nozzle size. To dispense fluid with the gun,

start the supply pump, disengage the trigger lock, and squeeze

the trigger in all the way. Fluid flow begings with the slightest

pressure and stops when trigger is released.

• At this point, the product will flow until reaching the gun and

you can start working.

START OF THE PAINTING OPERATIONS

• Use the equipment only after performing all the SETTING UP

operations described above.

To reduce the risk of serious injury, including

fluid injection or splashing in the eyes or on skin,

always follow the PRESSURE DISCHARGING

PROCEDURE whenever the dispensing equipment

is shut off, when checking or servicing any part

of system, when installing or changing nozzles

and whenever you stop dispensing.

Always engage the trigger lock when the gun is not

in use to prevent accidental triggering of the gun.

CONNECT PRODUCT HOSE

• Connect the flexible hose for product delivery

(P4)

to the fitting

(P5)

of the pump. Tighten the nut

(P6)

with a suitable wrench

(P7)

.

NEVER use sealants on fittings’ threads. It is

recommended to use the hose provided with the

standard kit. NEVER use a damaged or a repaired

flexible hose.

OPERATION

Q

Before starting the pump it is important that

a small amount of atomizing air is sent to the

spraygun.

Product delivery

hose

Air hose

P7

P4

P5

P6

P7

P4

P9

P8