www.larius.com

27

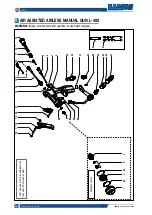

L400

REV.

02 - 02/2020 - Cod. 150085

* to order only the nozzle seal use the part num ber 21854. Air assisted airless nozzles codes are listed in chapter T.

** code 21832: spring 0-100 bar

code 21833: spring 0-250 bar

code 21834: spring 0-150 bar

Pos.

Code

Description

1

21811

Ring nut

2

21892

Air cap

3

*

Nozzle *

4

21920

Coupling group

5

21895

Complete coupling

6

21896

Gun body

7

21828

Valve guide

8

21897

Needle

9

21898

Air Valve

10

21831

Needle

11

18867

Spring

12

**

Spring

13

21835

Cap

14

12103

Ring UNI 7434-4

15

21899

Air adjusting fitting

16

21826

Air adjustment

16A

21806

Air adjustment - mod. mistclean

17

21849

Trigger pivot

18

21848

Trigger

19

21871

Nut

Pos.

Code

Description

20

21845

Trigger low pin

21

21846

Trigger lock

22

21836/1

Gasket

23

21837

Material house

24

270

Filter 100 mesh

25

21870

Fitting filter holder

26

7021

Gasket

27

11155

Revolving fitting

28

5338

Screw

29

4006

Quick connection

30

12572

O-ring

31

21863

O-ring

32

21877

Fitting

33

21865

O-ring

34

21823

Needle guide

35

21812

Gasket

36

21860

O-ring

37

21858

Tool

38

21890

Tool

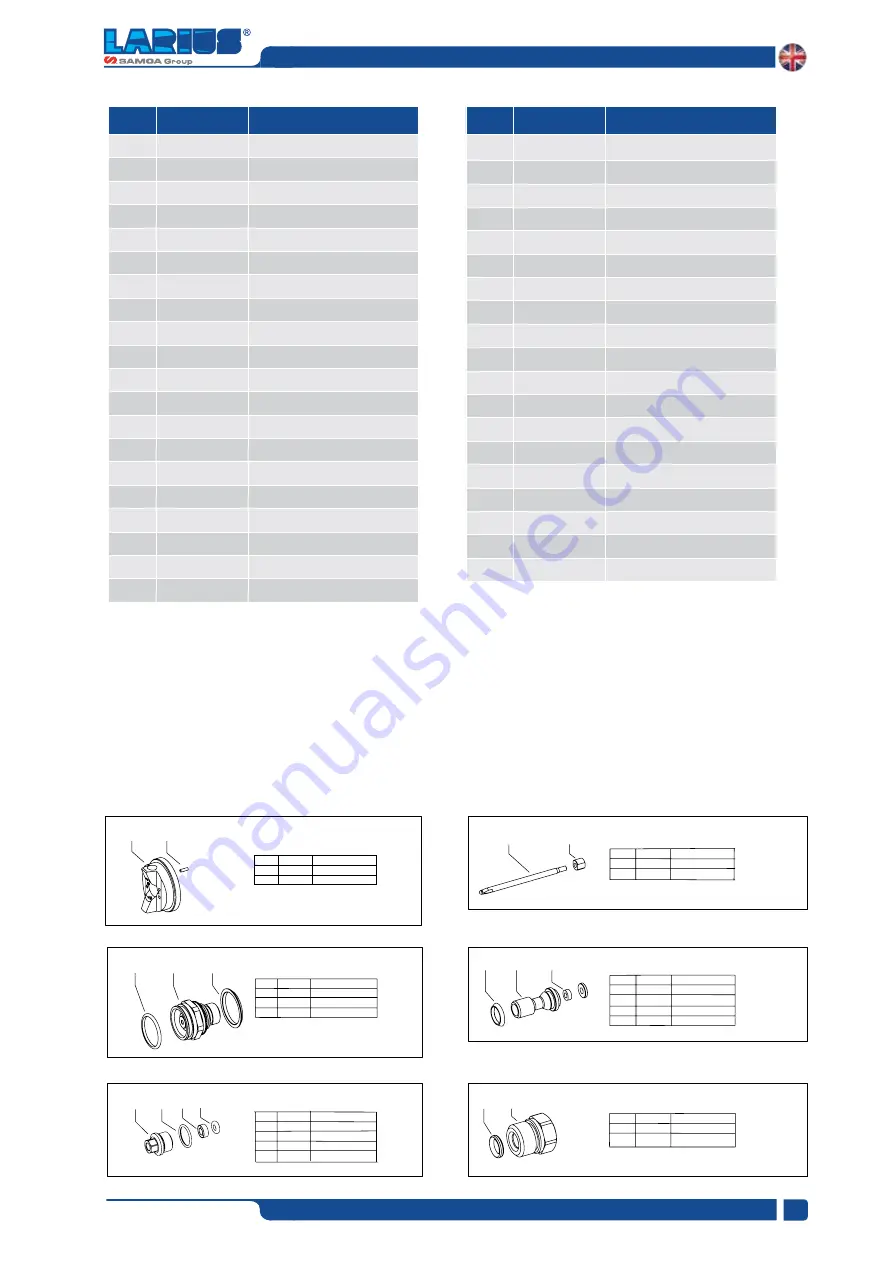

4a

4b

4c

5a 5b 5c

9a 9b

9c 9d

15a 15b

8a

8b

2a

2b

5d

POS. PART NO. DESCRIPTION

2a

21873

Air Cap

2b

21874

Nozzle Pin

POS. 4 - CODE 21894 - COUPLING GROUP

POS. PART NO. DESCRIPTION

4a

O-ring

21864

4b

21922

Coupling

4c

21818

Gasket

POS. 5 - CODE 21895 - GASKET GROUP

POS. PART. NO. DESCRIPTION

5a

21874

Seat Gasket

5b

21862 O-ring

5c

5d

11955

4077

POS. 8 - CODE 21897 - NEEDLE

POS. PART NO. DESCRIPTION

8a

21827

Needle

8b

21857

Nut

POS. PART NO. DESCRIPTION

9a

21829

Gasket

9b

21830

Valve

9c

21885

Gasket

9d

21830/1

Block

POS. 9 - CODE 21898 - AIR VALVE GROUP

POS. 15 - CODE 21899 - ADJUSTING FITTING GROUP

POS. PART NO.

DESCRIPTION

15a

301013

O-ring

15b

21824

Air Adjusting Fitting

POS. 2 - CODE 21892 - AIR CAP GROUP