www.larius.com

10

GHIBLI 30:1/40:1

REV.

. 01 - 03/2020 - Cod. 150088

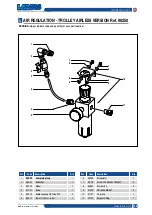

"AIR

ASSISTED

AIRLESS"

H2

H1

AIR ASSISTED

AIRLESS

H5

H3

H3

H4

H6

AIRLESS

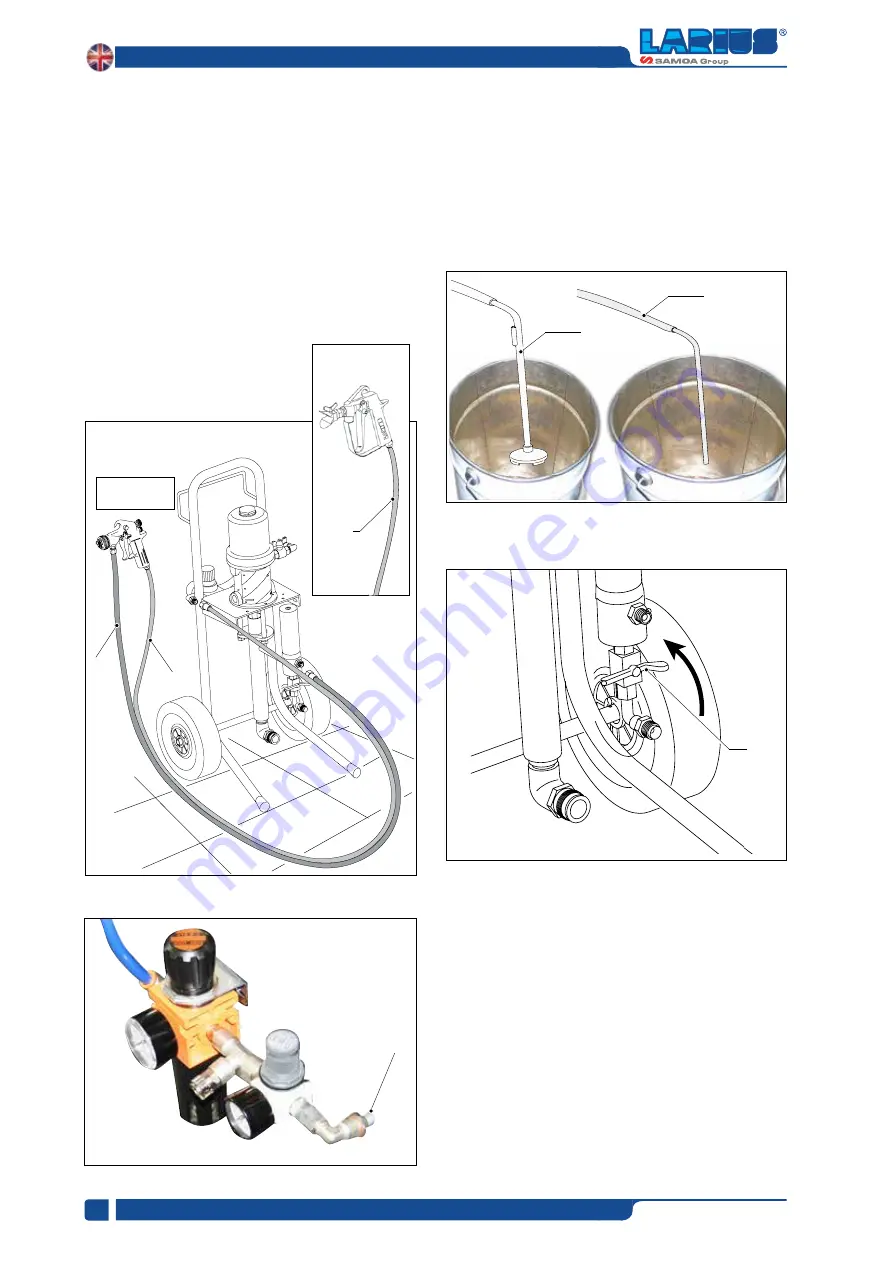

CONNECTION OF SUCTION AND RECIRCULATING PIPES

AIRLESS version

•

Connect the high pressure flexible hose

(H3)

to the pump and

to the spray gun, paying attention to tighten the fittings strongly

(

the use of two spanners is suggested

).

Do not use sealant agents

for fitting threads.

• Make sure the spray gun is without the atomization nozzle.

"AIR ASSISTED AIRLESS" version

For the "AIR ASSISTED AIRLESS" version, connect tube

(H3)

,

as well as the air supply hose

(H4)

,

to the air reducer unit

(H5)

.

WASHING OF THE BRAND-NEW EQUIPMENT

• The equipment has been tested at our plant with light mineral

oil left inside of the pumping element as protection. Therefore,

before sucking the product, carry out a washing using a diluent.

• Dip the suction hose

(H1)

into the tank of the washing.

• Insert the recirculating pipe

(H2)

into a container (

a metal

container is suggested

).

• Open the recirculating cock

(H6)

.

• Set the pump feed pressure at about 3 bar and open the air

passage valve.

• The pump will start working and will drain oil from the recirculating

pipe. Close the recirculating cock as soon as the clean solvent

has come out.

• Lift the solvent tank’s suction tube.

• Lean the spray gun against the rim of the container

(H7)

a

nd

drain the residual oil pressing the trigger. Release the trigger as

soon as the clean solvent comes out.

• Point the spray gun at the tank of the solvent and press the

trigger so as to recover the clean solvent left inside the pump.

• As an accelerated working of the pump (

the pump "idles"

)

appears, close the air passage valve.

Fig. 3H

Fig. 4H

Fig. 5H

Fig. 6H