1

2

3

4

5

1

2

3

5

4

www.larius.com

32

ED. 04 - 04/2021 - Cod. 150183

LARIUS GHIBLI MIX 2K

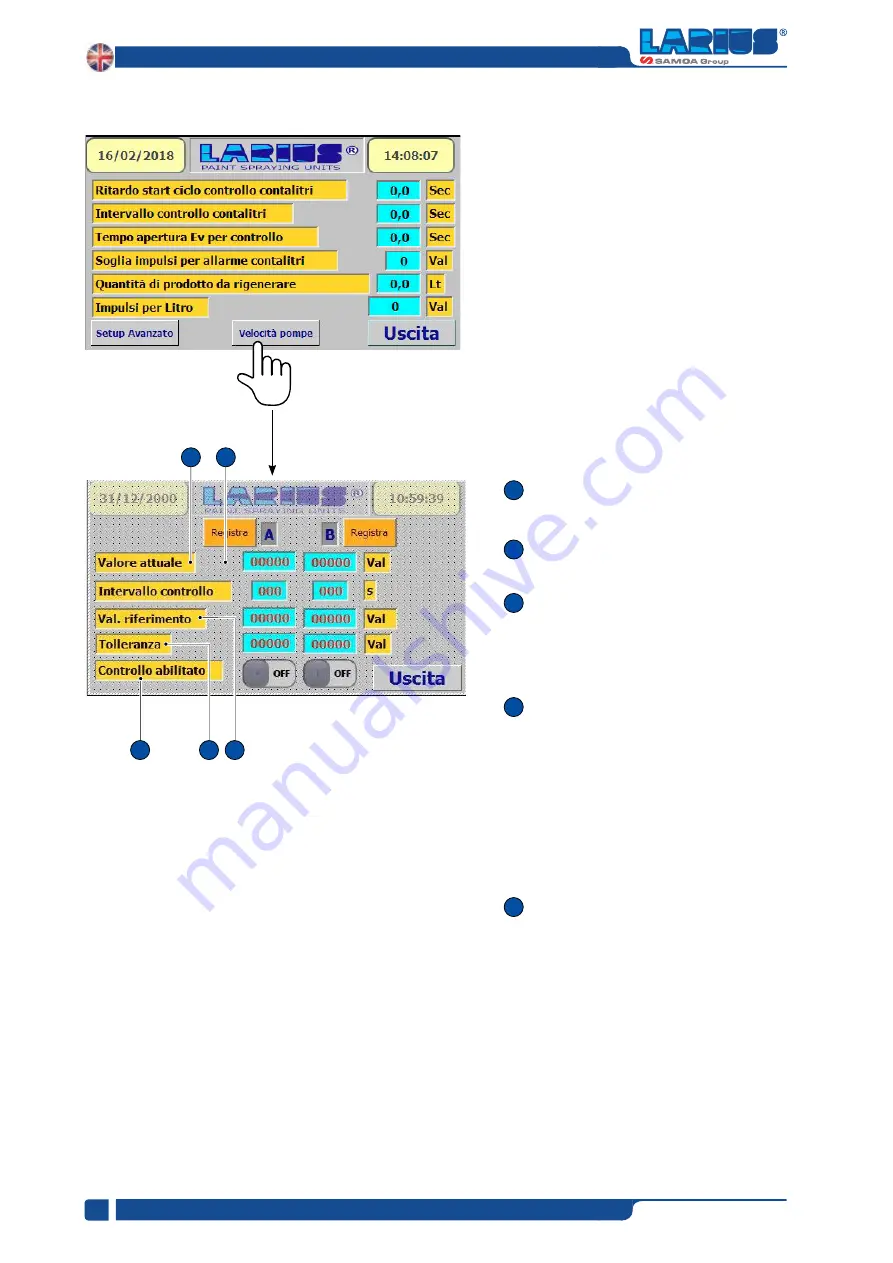

PUMPS CALIBRATION

Current value:

The value displayed when the

machine is in automatic mixing conditions.

Control interval:

Time, in seconds, between

repeated reading of the current value.

Reference value:

press this button to record the

field value (current value). The current value will

be recorded in the Reference val. box.

The value can also be entered directly onto the

virtual keypad.

Tolerance:

Value of the tolerance that the machine

considers more with respect to the reference value

which determines the pump speed alarm.

For example,

reference value: 1000; tolerance

value: 220, maximum value: 1220. If the current

value is higher than 1220, the machine alarm is

ON after the time set on the next page.

Check enable:

Control enabled; the control is

enabled by moving the cursor to the right and the

message ON appears.

Procedure for storing values:

- set the control “pause control” (i.e. 5 seconds).

- With the machine in automatic mode and while

the operator is carrying out normal piece painting

operations, make sure that “check enable”is set

to the “OFF” position

- press the “Record A” button. The value read in

“Setpoint value” will be transferred to the “Current

Value” box.

Fix a tolerance value (i.e. 50).

Repeat this operation for pump B.

Enable the controls using the cursors, setting

them to

ON.

It allows you to record the pumping speed, in working condition after

having set all the parameters relating to the type of ratio A:B forecasts

of work type of nozzle used, in order to determine the increase in speed,

index of malfunction of the system product suction.

Example: no product or suction filters clogged.

In these conditions, the pump cavitates, increasing the speed.